Metal gasket blanking die for machining

A metal gasket and mechanical processing technology, applied in the direction of pushing out equipment, etc., can solve the problems of accumulation inside the blanking hole, unsmooth discharge, easy scratching of the wall of the blanking hole, etc., so as to avoid accumulation and facilitate discharge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

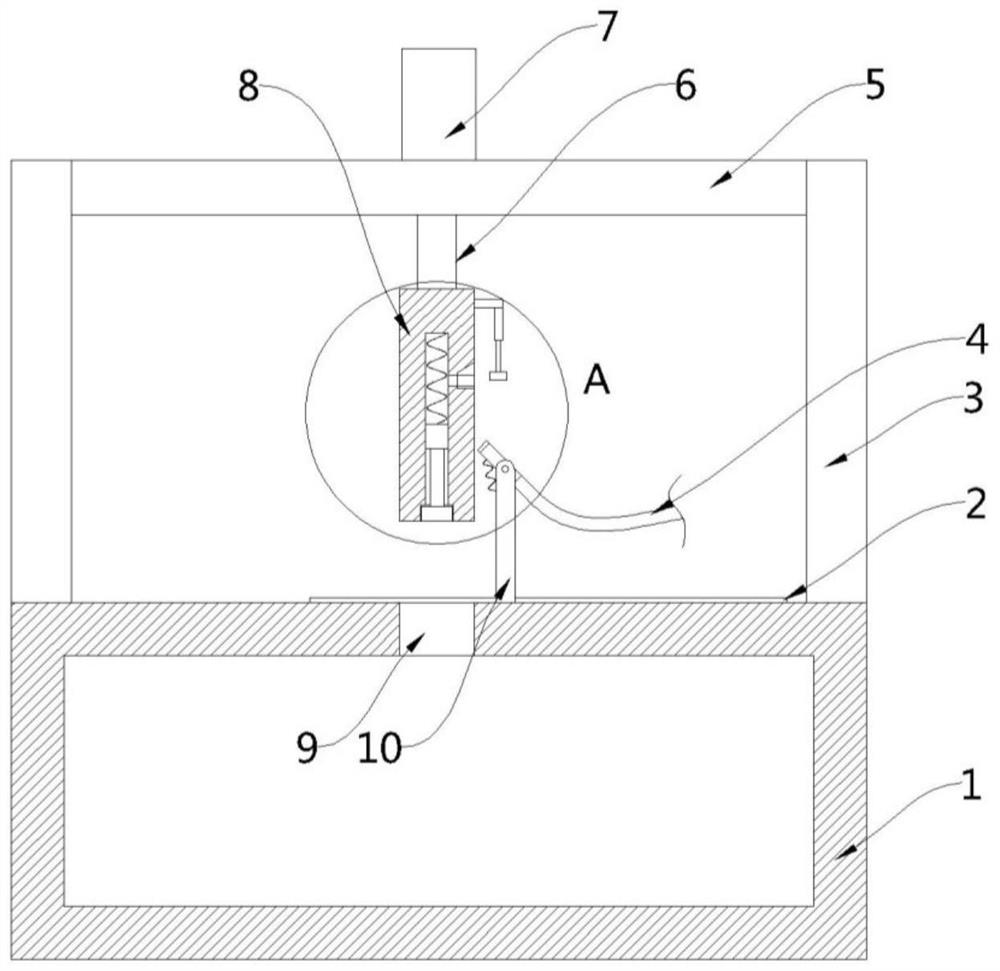

[0024] see Figure 1-3 , this embodiment provides a metal gasket blanking die for mechanical processing, including a bottom box 1, a blanking hole 9 is opened in the upper middle of the bottom box 1, and two groups of mutually symmetrical holes are fixed on the upper edge of the bottom box 1 Support vertical plate 3, two groups of support vertical plate 3 tops are connected by support horizontal plate 5, between two groups of support vertical plate 3, be provided with punching tool 8 corresponding to described blanking hole 9, described support horizontal plate 5 A power assembly for driving the punching tool 8 to move downward is installed on the top, a limiting groove 15 is provided at the bottom of the punching tool 8, and an installation channel 11 communicating with the limiting groove 15 is arranged inside the punching tool 8 , the inside of the limiting groove 15 is movably embedded with a pusher head 16, the inside of the installation channel 11 is movably provided wit...

Embodiment 2

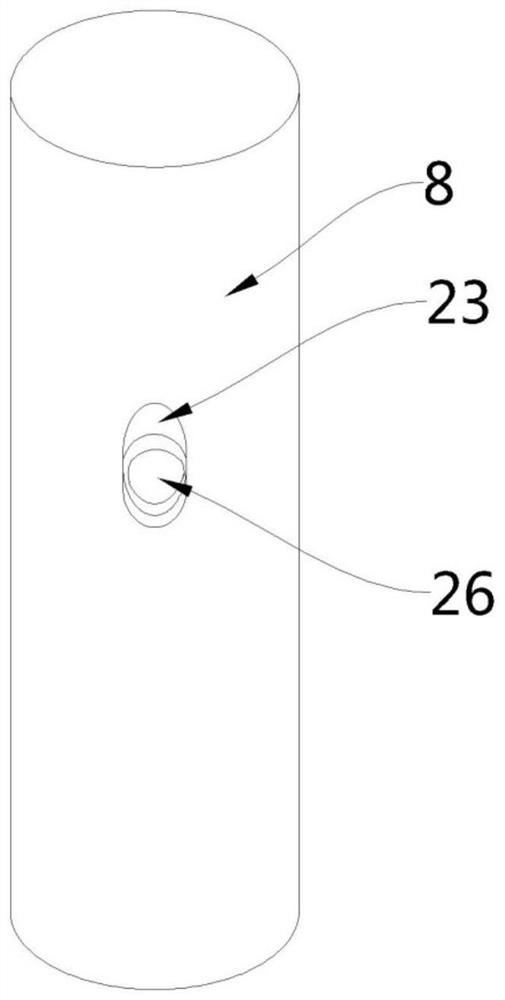

[0033] see figure 2, a metal gasket blanking die for mechanical processing. Compared with Embodiment 1, the end of the intake hard pipe 17 away from the intake hose 4 is also provided with a sealing ring 20 in this embodiment. 17 is transferred from the wedge-shaped notch 23 to the inside of the air intake hole 26, and the sealing ring 20 abuts against the inner wall of the air intake hole 26, thereby improving the sealing effect and ensuring that the compressed air can smoothly drive the piston 13, The connecting rod 14 and the pushing head 16 move down.

[0034] Specifically, the sealing ring 20 is made of rubber material.

[0035] In the embodiment of the present invention, after the blanking tool 8 punches the metal substrate 2, the pressure tube assembly can drive the intake hard tube 17 to rotate, so that one end of the intake hard tube 17 is docked with the air intake hole 26, and the external supply is used to The pneumatic equipment injects compressed air into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com