Dedusting device for construction site

A construction site and dust removal device technology, applied in the direction of separation device, liquid separation agent, membrane technology, etc., can solve the problems of dust floating outside, increase people's labor intensity, etc., and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

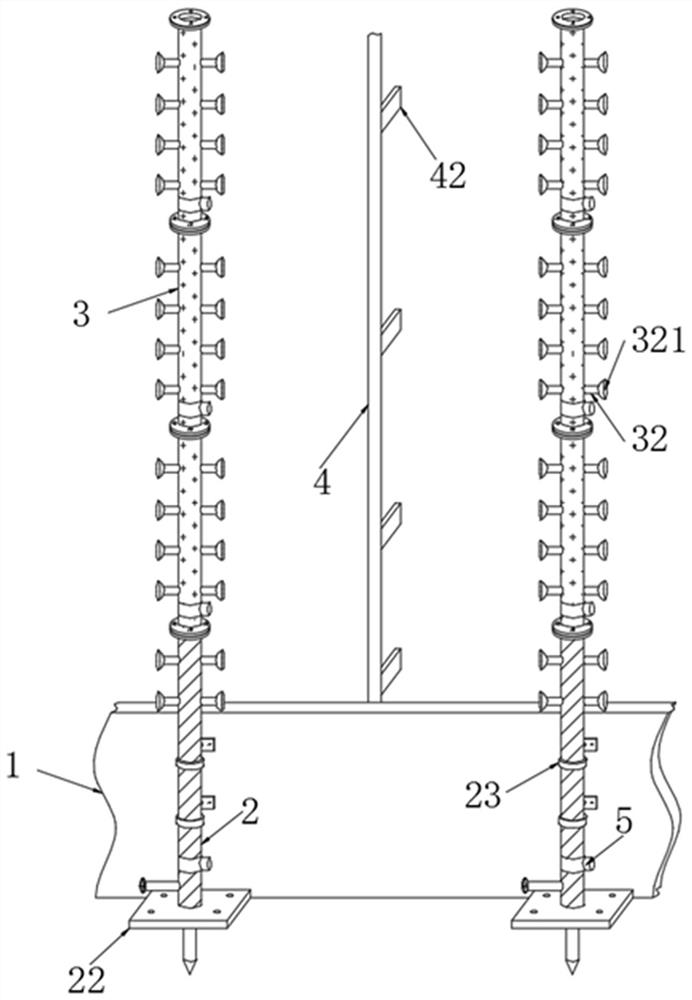

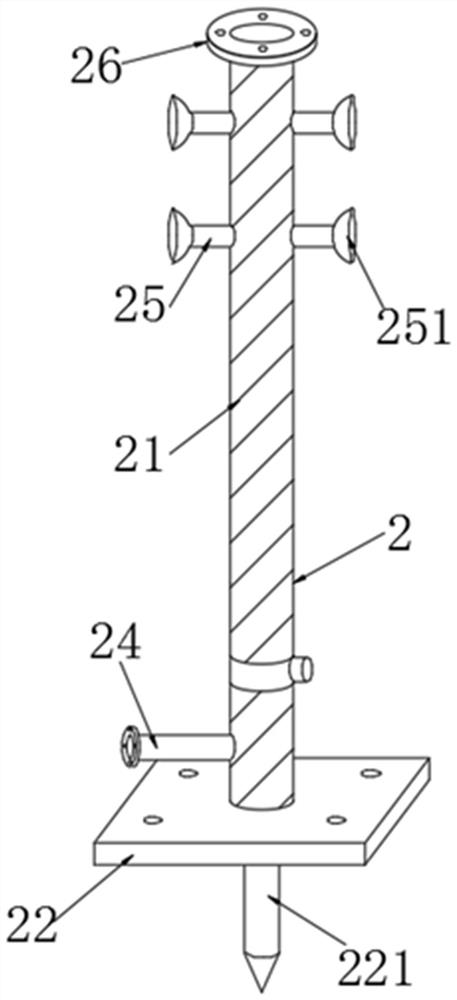

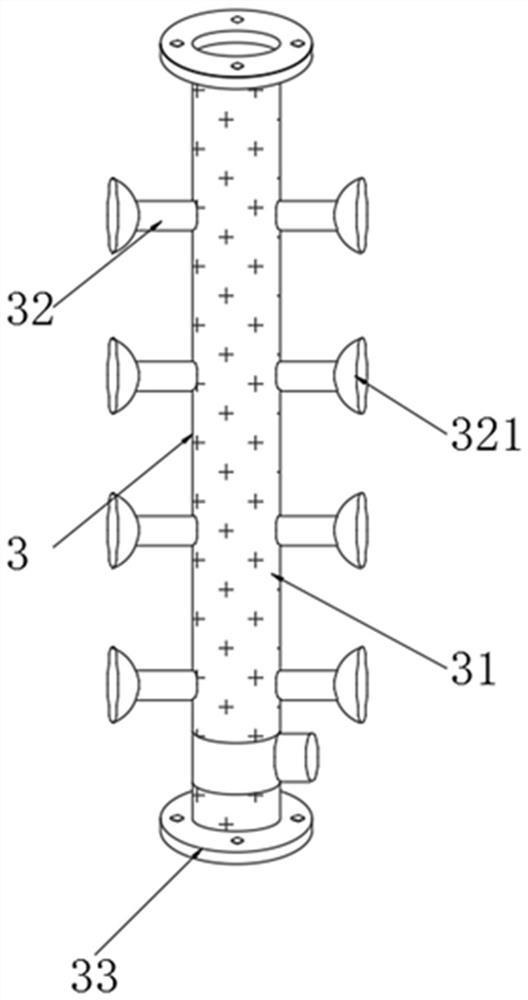

[0025] see Figure 1-6 , in an embodiment of the present invention, a dust removal device for a construction site, including a construction site enclosure wall (1), a support bottom pipe (2), a water delivery pipe (3) and a detection rod (4), the support bottom pipe (2) is located in the building On one side of the construction site wall (1), the bottom of the support bottom tube (2) is fixedly connected with the installation base plate (22), and the outer wall of the support bottom tube (2) is covered with a fixed collar (23), and the outer wall of the fixed collar (23) is fixed A fixed rod (231) is connected, and the end of the fixed rod (231) close to the construction site wall (1) is fixedly connected with a fixed plate (232), and the fixed plate (232) is detachably connected with the construction site wall (1) to support the bottom pipe (2) The bottom is fixedly connected with the water inlet pipe (24), and the water inlet pipe (24) is connected with the external water pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com