Electrostatic protection circuit and wire stripper

A technology of electrostatic protection and wire stripper, which is applied in the direction of emergency protection circuit devices, circuit devices, emergency protection circuit devices for limiting overcurrent/overvoltage, etc., which can solve the problem of interfering with the operation of the single board CPU and inability to accurately guide the knife adjustment The angle and position of the wire stripper need to be repeatedly debugged to achieve the effect of reducing differential mode interference, reducing interference energy, and realizing a safe closed loop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] An embodiment of the present invention is an electrostatic protection circuit and a wire stripper, which are used to ensure that the electrostatic interference between the equipment itself and the overhead line generated during the rotation of the wire stripper can be effectively discharged and isolated.

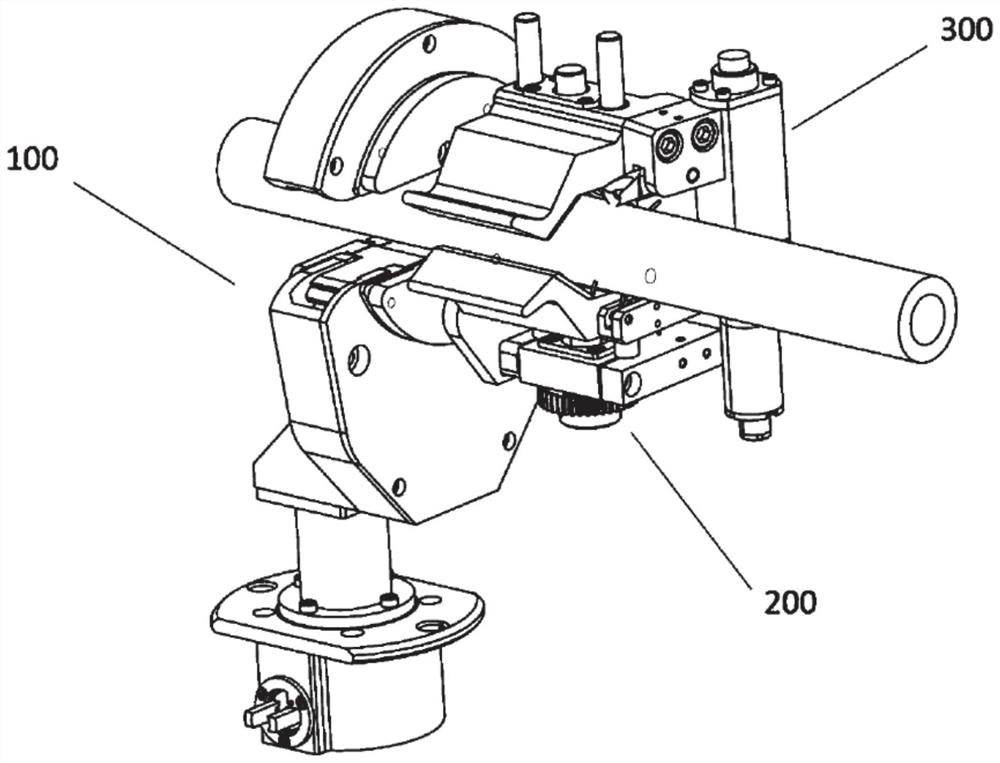

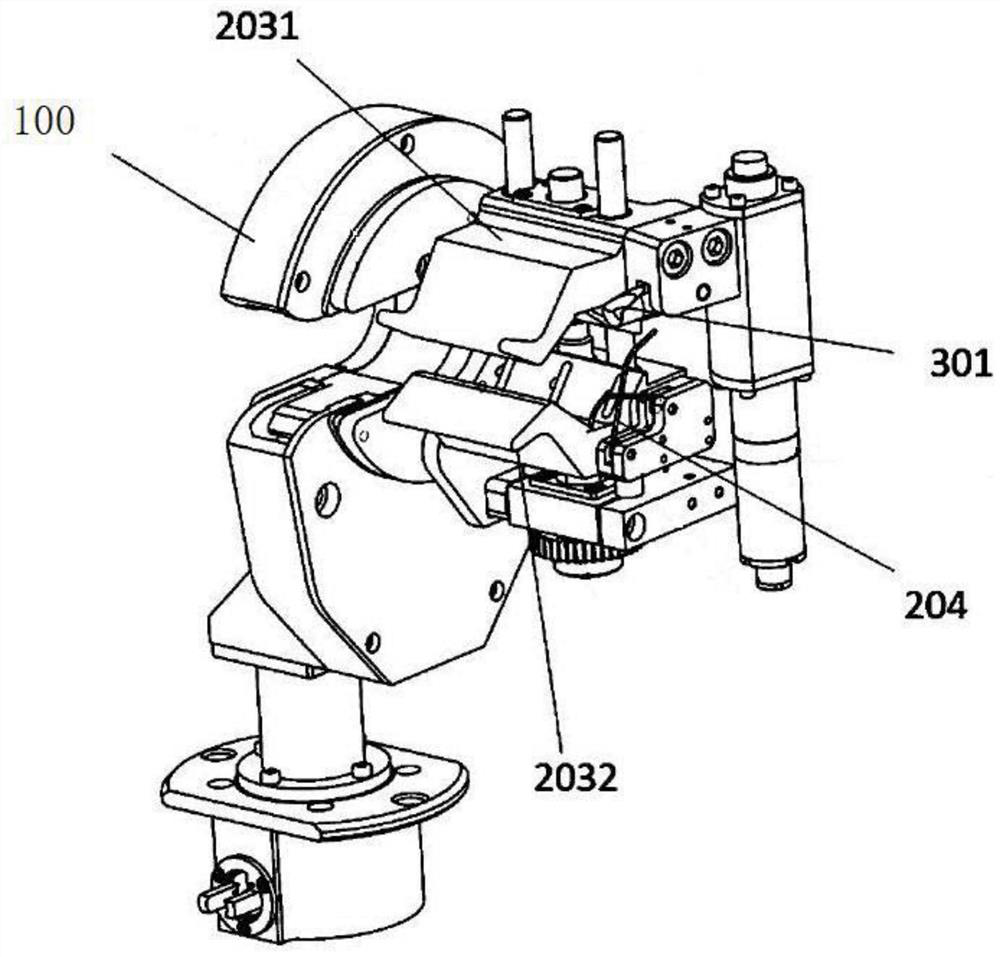

[0034] Such as Figure 1~3 As shown, the wire stripper using the electrostatic protection circuit of this embodiment is used to dynamically adjust the angle of the cutter head for stripping on a 10KV overhead line, including:

[0035] The wire clamp module 200 includes an upper clamping block 2031 and a lower clamping block 2032 for clamping the wires. The clamping surfaces of the upper clamping block 2031 and the lower clamping block 2032 are provided with several mutually parallel clamps inclined toward the wires and the incoming wire direction. Bump 2034;

[0036] The stripping module 300 includes a cutter head 301 for stripping, and the cutter head 301 is parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com