Method for quickly analyzing landing load of support arm type undercarriage

A rapid analysis and landing gear technology, applied in geometric CAD, design optimization/simulation, special data processing applications, etc., can solve problems such as unexisted, low use requirements, complex landing gear design, etc., to achieve simple derivation process and meet engineering requirements Design requirements, effective and reliable effects of landing loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

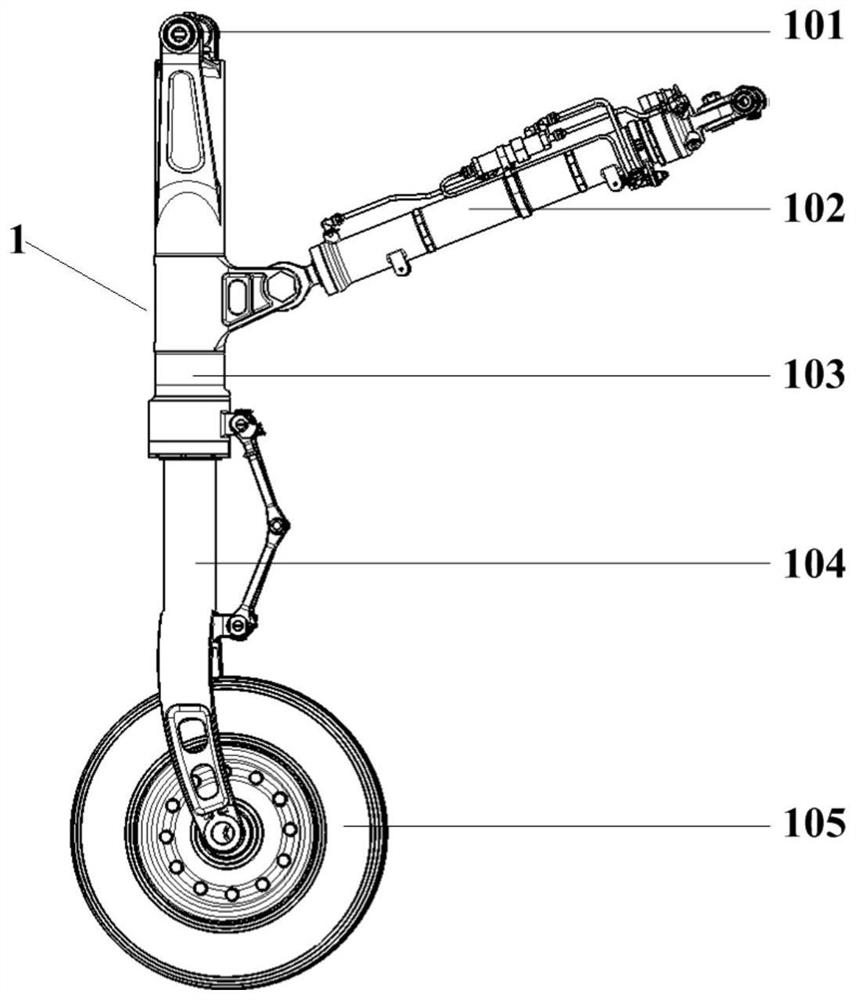

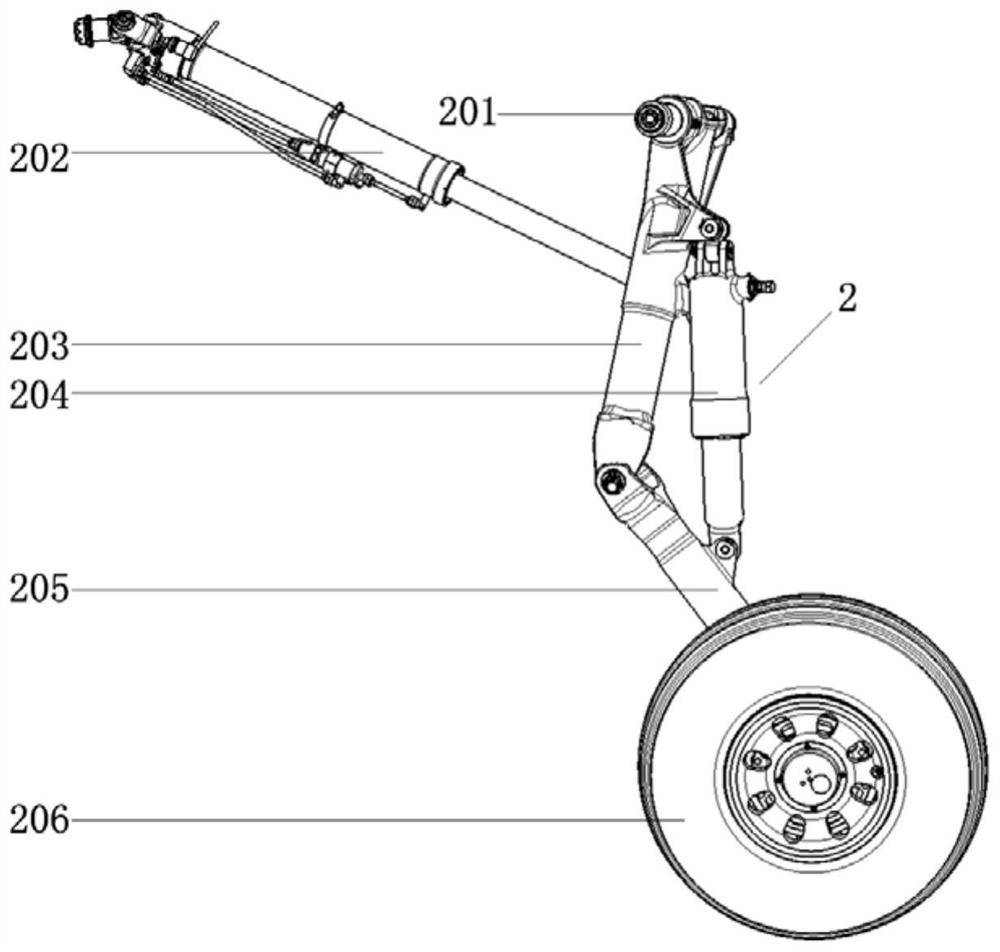

[0057] The invention deduces a fast engineering calculation method for the maximum landing load when the landing gear lands, thereby providing a simple and effective engineering method for calculating the landing load of the large-side-angle support arm type landing gear.

[0058] The specific implementation process of the rapid analysis method for the landing load of the outrigger landing gear proposed by the present invention is as follows:

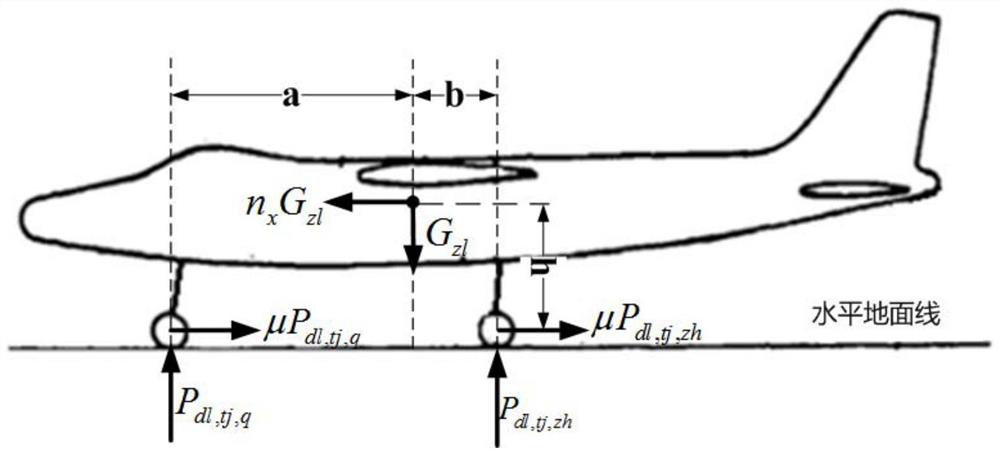

[0059] (1) For the cantilever landing gear structure, there is also an energy conservation equation: total energy A = tire absorbed energy A lt +Structure deformation of outrigger landing gear absorbs energy A zb + Body structure deformation absorbs energy A jt .

[0060] In the later stage of the landing gear drop test, if the maximum vertical load P measured in the drop test exceeds the load design requirement, and the design variable of the large-side angle support arm type landing gear is limited, only through the Minimize tire p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com