Rubber head shape-preserving device and method for bonding of precision optical-mechanical system

An opto-mechanical and bonding technology, which is applied in the field of precision opto-mechanical design and assembly, can solve the problems of affecting the shape of the bonding area of the bonding area, affecting the surface quality of optical parts, and difficult to constrain the shape of the adhesive, so as to ensure the strength and reduce the Uncontrolled risks, the effect of improving controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

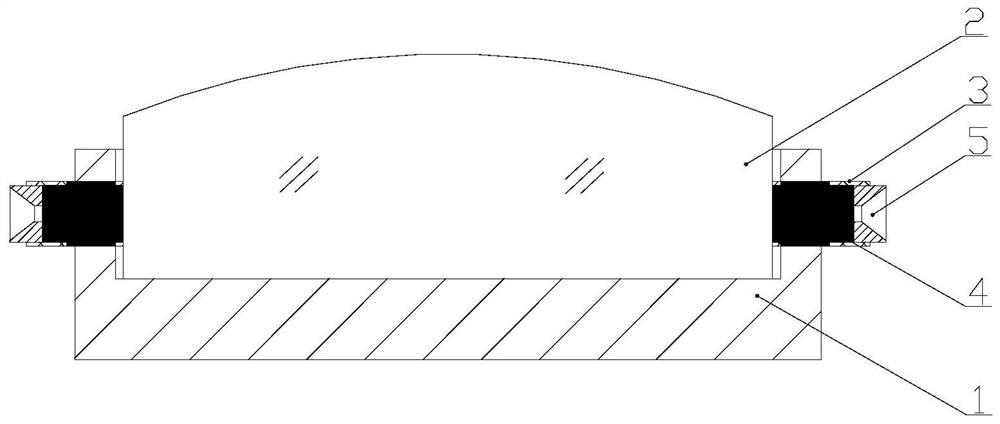

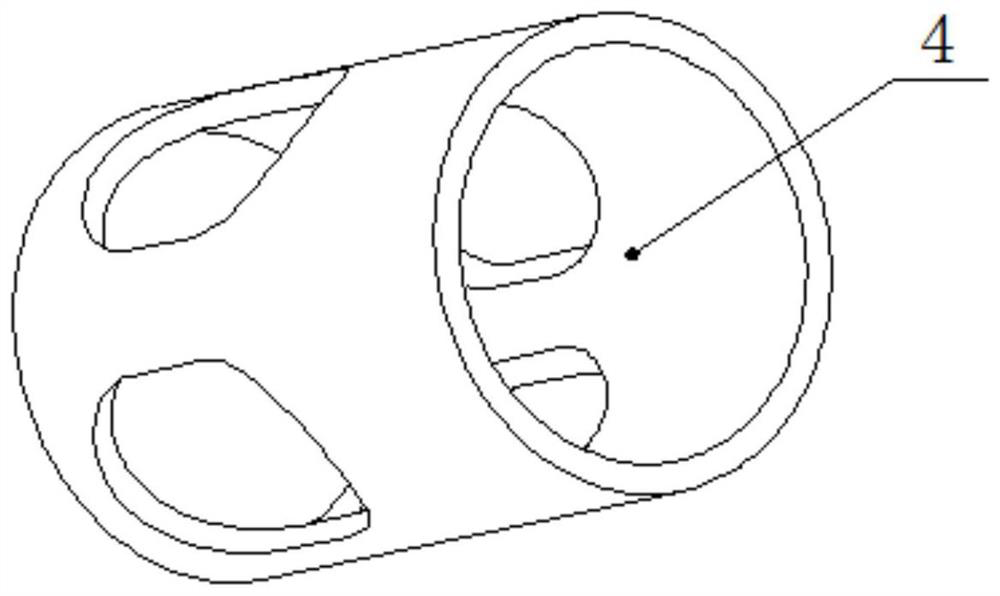

[0025] Such as figure 1 As shown, the glue head shape-preserving device used for precision opto-mechanical system bonding of the present invention includes a main mirror frame 1, an optical part 2, an adhesive 3, a shape-preserving tooling 4 and a plug 5; the optical part 2 is placed on the main mirror frame 1 Inside, the optical axis of the optical part 2 coincides with the central axis of the cylindrical main mirror frame 1; the main mirror frame 1 is provided with a glue injection hole, the shape-preserving tool 4 is closely matched with the glue injection hole, and the inner end surface of the shape-keeping tool 4 is in contact with the optical part 2 is in contact with the outer surface of the shape-keeping toolin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com