Novel efficient energy-gathering cutting device

A cutting device and high-efficiency technology, which is applied in the field of blasting, can solve the problems of not being able to provide sufficient penetration ability, and achieve the effect of improving penetration ability, cutting efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

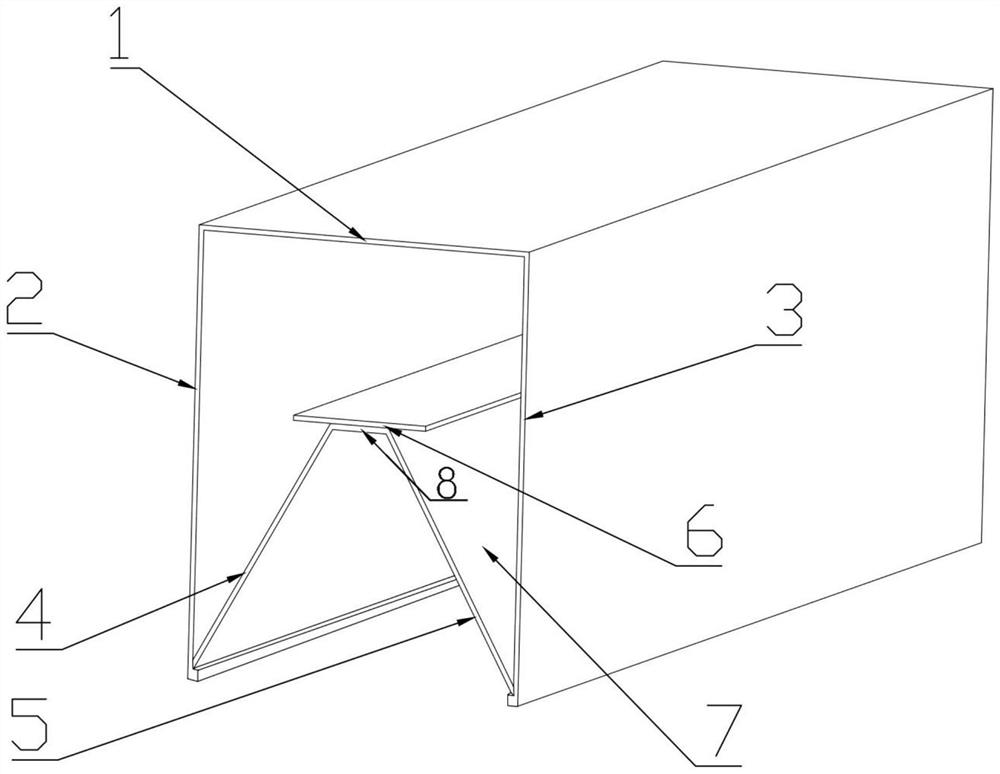

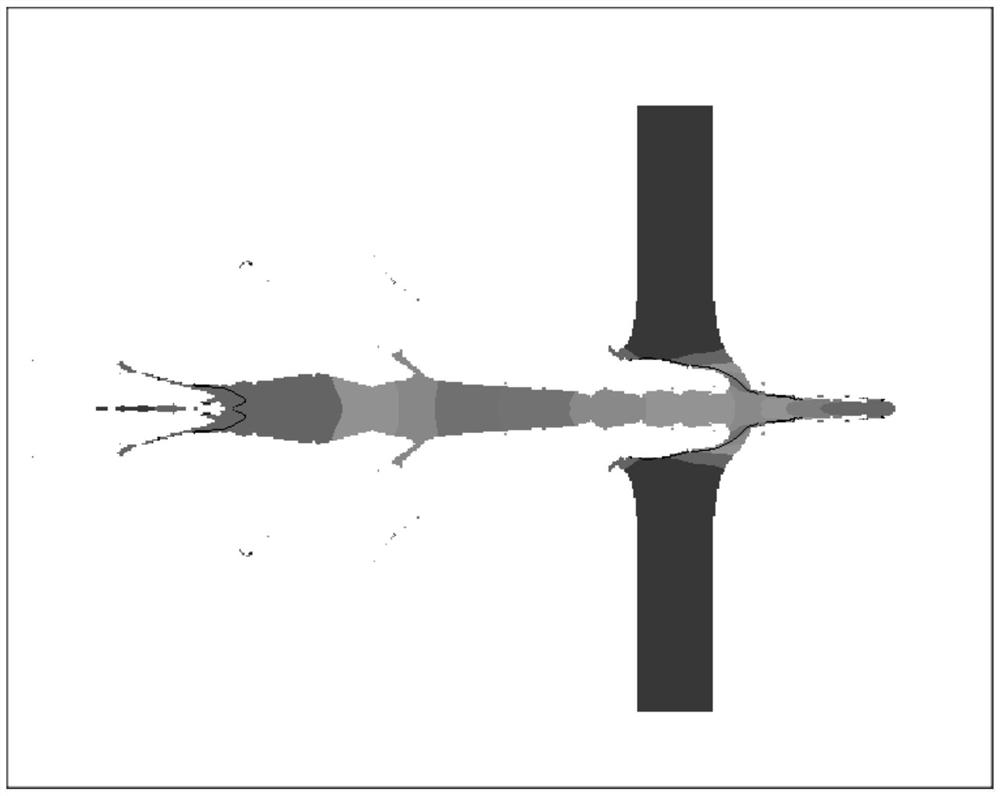

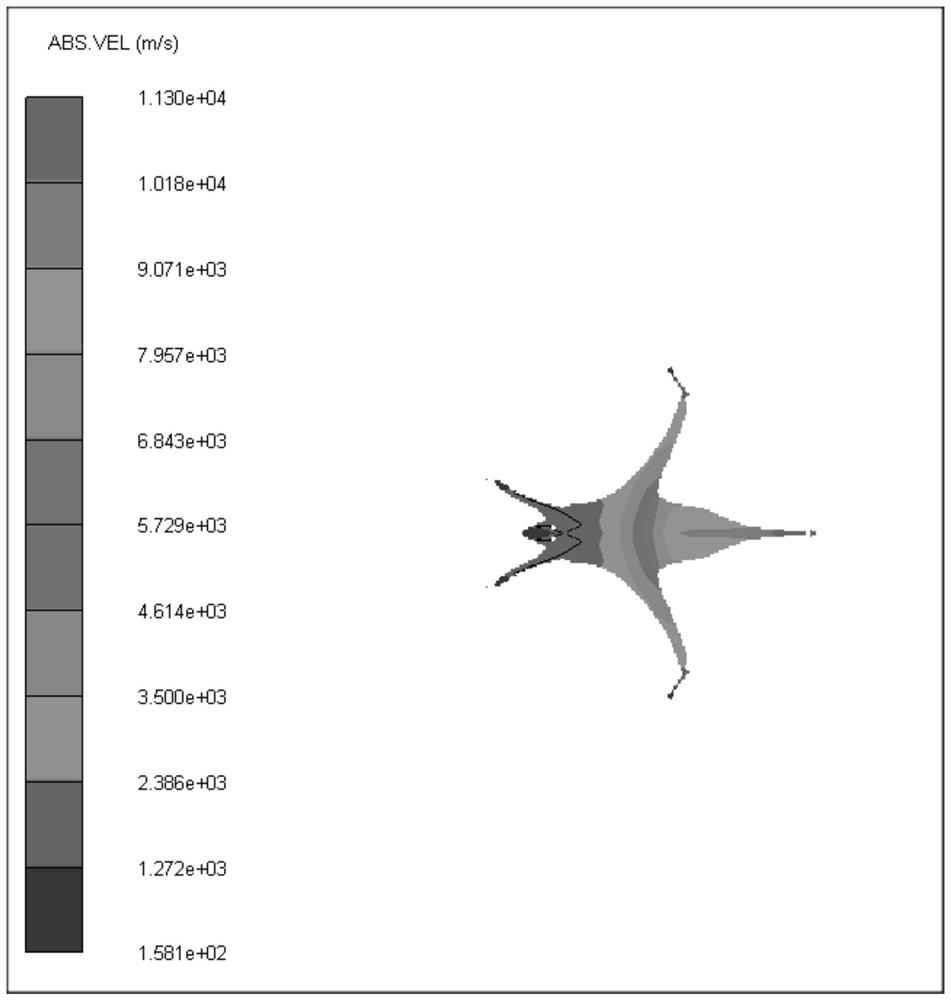

[0030] Such as Figure 1-2 As shown, the present invention provides a novel high-efficiency linear energy-gathering cutting device, comprising: a charge shell, a charge cover, an auxiliary structure 6 and a charge 7, and the charge shell is a plate-like structure with a door-shaped cross section. The charge shell includes a charge top plate 1, a charge side plate I2 and a charge side plate II3, and the charge top plate 1, the charge side plate I2 and the charge side plate II3 are strip plates structure, the charge side plate I2 and the charge side plate II3 are arranged parallel to each other at the lower ends of the two sides of the charge top plate 1; the drug-shaped cover includes a drug-shaped cover I4 and a drug-shaped cover II5, the The drug-type cover I4 and the drug-type cover II5 are plate-shaped structures, the lower end of the drug-type cover I4 is connected to the inner lower end of the side plate I2 of the charge 7, and the drug-type cover II5 is connected to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com