Double-roller rope pressing mechanism for winch rope arrangement

A rope pressing mechanism and double roller technology are applied in the field of hoisting and lifting machinery, which can solve the problems of inconvenient winding, complicated process, affecting the winding space, etc., and achieve the effects of easy production and procurement, simple production process, and easy popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

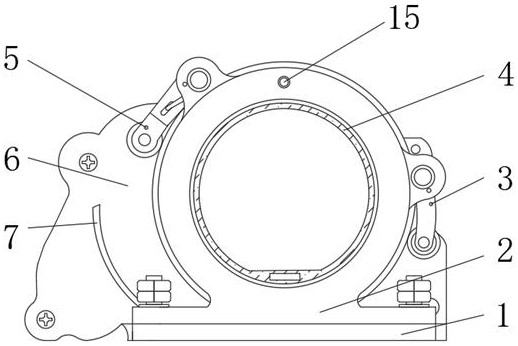

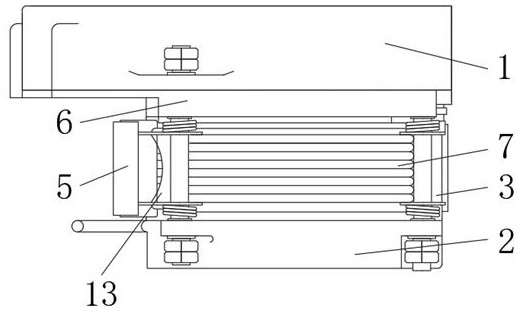

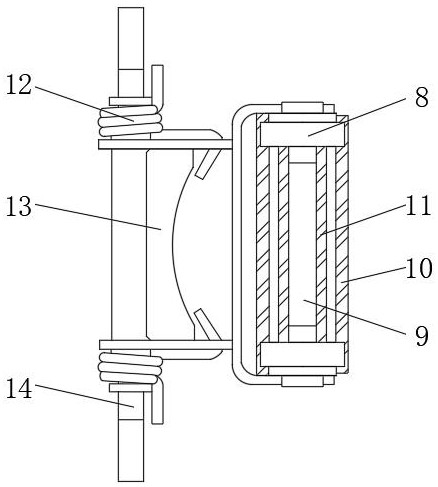

[0025] Embodiment one, by Figure 1-6 Provide, the present invention comprises base 1, and the top of base 1 is equipped with front support 2, and a side of front support 2 is equipped with right steel rope presser 3, and the inside of front support 2 is equipped with roller 4, and the other side of front support 2 A left steel rope compactor 5 is installed on one side, a rear bracket 6 is installed on the back of the drum 4, a steel wire rope 7 is installed on the surface of the rear bracket 6, a rolling bearing 8 is installed on the surface of the rear bracket 6, and a compactor is installed on the bottom of the rolling bearing 8. Axle 9, roller 10 is installed on the side of compression wheel 9, auxiliary bushing 11 is installed on the surface of roller 10, auxiliary bracket 13 is installed on the side of rolling bearing 8, bracket torsion spring 12 is installed on the top of auxiliary bracket 13, auxiliary bracket 13 The bottom of the bracket sleeve shaft 14 is installed, ...

Embodiment 2

[0026] Embodiment 2, on the basis of Embodiment 1, the surface of the front bracket 2 is provided with a retention hole, and the inner cavity of the retention hole on the front bracket 2 is threadedly connected with one end of the first screw 15, through the setting of the front bracket 2 , so that it utilizes the cavity of the retention hole and one end of the first screw 15 to realize the installation of the retention bracket 16 on the front bracket 2 .

Embodiment 3

[0027] Embodiment three, on the basis of embodiment one, the rollers 10 on the right steel rope compactor 3 and the left steel rope compactor 5 are all distributed on both sides of the drum 4, and the right steel rope compactor 3 and the left The steel rope compactor 5 has the same size, and the right steel rope compactor 3 and the left steel rope compactor 5 are respectively installed on the surface of the rear support 6 and the front support 2, and by the setting of the right steel rope compactor 3, its Cooperate with the left steel rope presser 5 and the roller 10, so that both sides of the drum 4 always force the steel wire rope 7 to be evenly pressed on the winding part of the drum 4, effectively preventing the local loosening and disorder of the steel wire rope 7 on the drum 4. Both the rope clamp 3 and the left steel rope clamp 5 cooperate with the bracket torsion spring 12, and the two bracket torsion springs 12 act at the same time during operation, on the one hand, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com