Feeding device for hot process regeneration equipment

A feeding device, thermal regeneration technology, applied in packaging, loading/unloading, transportation and packaging, etc., can solve problems such as inability to stably feed, inability to automatically feed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

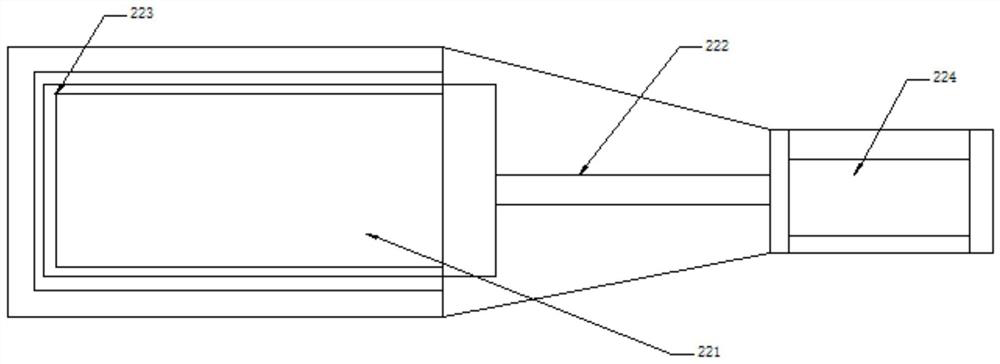

[0019] The present invention provides a fully automatic control device suitable for thermal regeneration in the case of high impurities and large particles, which includes a material storage warehouse 100, an automatic slide valve 200, a flexible star unloader 300, an automatic Control cabinet 400.

[0020] The automatic gate valve 200 is located under the material storage warehouse 100, and can automatically control the size of the outflow of materials from the material storage warehouse. The flexible star unloader 300 is located under the automatic gate valve 200, which can realize the material discharging speed and the material discharge rate. The amount of control, the automatic control cabinet 400 can realize the real-time interlocking of the thermal regeneration equipment and the automatic control of the automatic slide valve 200 and the flexible star unloader 300 according to the demand of the thermal regeneration material, so as to realize the high impurity of the mater...

Embodiment 2

[0026]The automatic control cabinet 400 is connected upwards to the thermal regeneration equipment, including the manual knob 410 for the opening of the gate valve, the rotation speed adjustment knob 420, the display screen 430, the connection line for the automatic gate valve 440, the connection line for the flexible star unloader 441, the thermal French connecting line 442. The automatic control cabinet 400 obtains the real-time material demand, connects the automatic gate valve and the flexible star unloader through the automatic gate valve connecting line 440 and the flexible star unloader connecting line 441 respectively, and connects through the thermal method connecting line 442 Thermal regeneration equipment. The automatic control cabinet 400 is used to control the interlocking of thermal regeneration equipment and the automatic gate valve and flexible star unloader, so that the automatic gate valve and flexible star unloader can be realized in real time according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com