Single-leg device of double-parallel four-rod transmission mechanism and six-wheeled leg robot

A transmission mechanism, dual-parallel technology, used in motor vehicles, transportation and packaging, etc., can solve the problems of non-unique motion and limited working space of robots, achieve efficient and complex terrain passing ability, increase the range of motion, and the range of motion added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

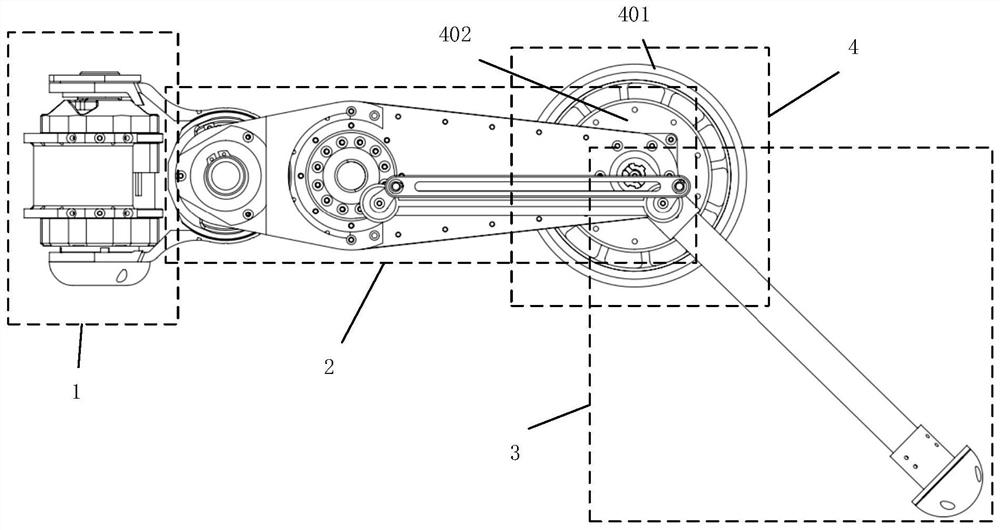

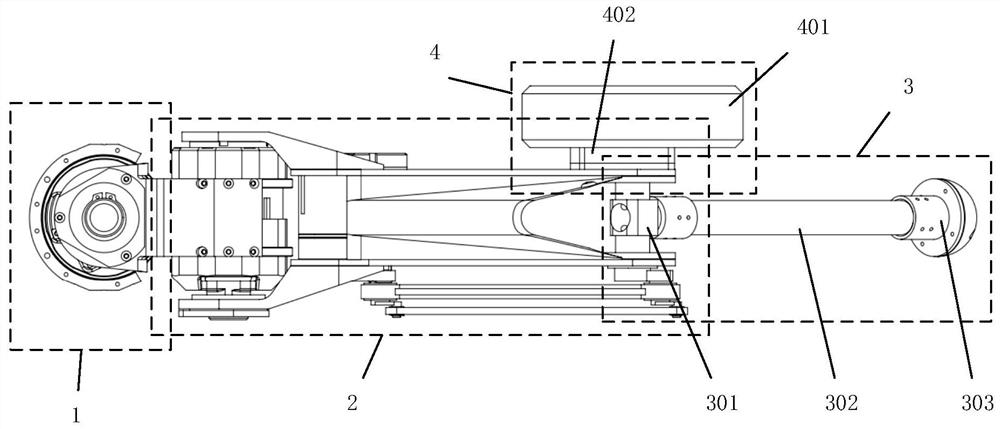

[0046] The single-leg device of the double parallel four-bar transmission mechanism of the present invention comprises a base part 1, a thigh part 2, and a lower leg part 3, such as figure 1 , figure 2 shown.

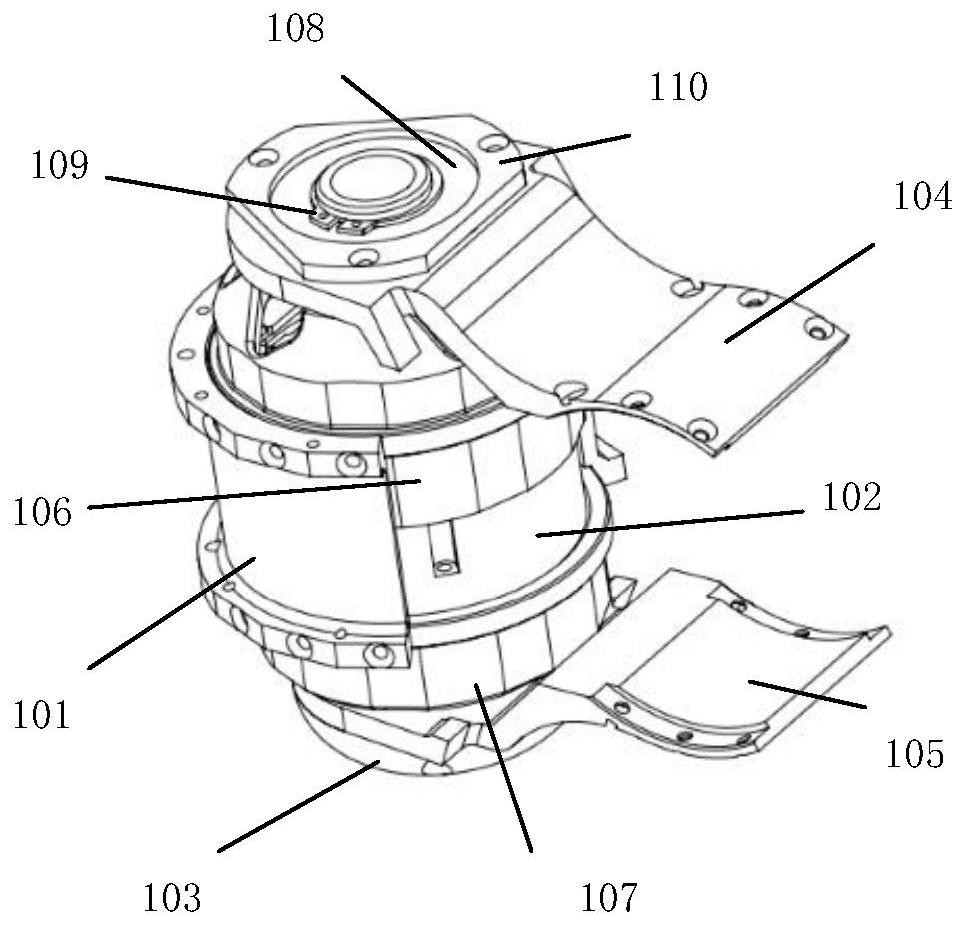

[0047] The base joint component 1 includes a fuselage connector 101, a lumbar joint drive motor 102, a base joint cushion 103, an upper base joint connector 104, a base joint connector lower 105, a waist joint drive motor kit upper 106, a waist joint drive The lower part of the motor kit 107 , the first bearing 108 , the retaining ring 109 for the first shaft and the first bearing pressure plate 110 . Such as image 3 , Figure 4 shown.

[0048]Wherein, the axis of the lumbar joint drive motor 102 is set perpendicular to the horizontal plane, and the upper and lower ends of the lumbar joint drive motor set 106 and the lower lumbar joint dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com