Baking trailer plate in PCB production process

A production process and baking car technology, which is applied in the field of baking car boards, can solve the problems of no fixing mechanism, PCB board rack slipping, inconvenient PCB board rack moving mechanism fixing or unfixing, etc., so as to reduce accidental damage and avoid slipping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

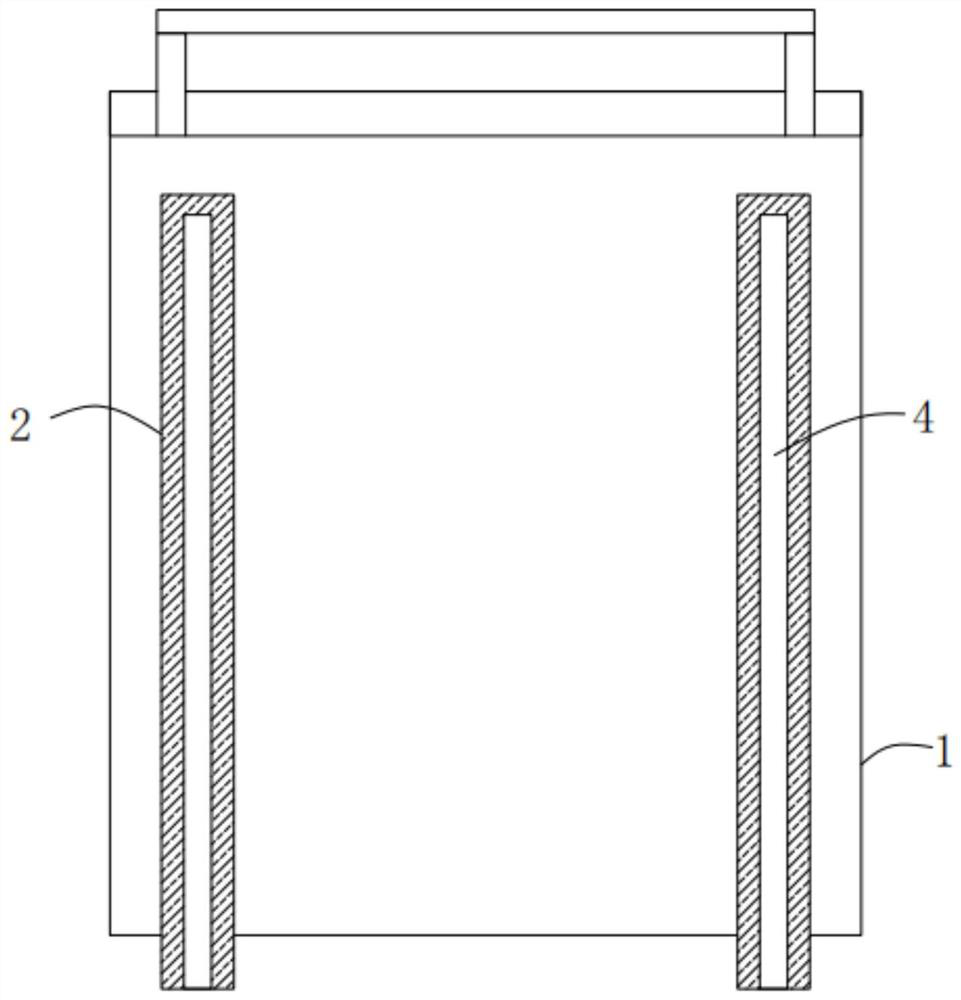

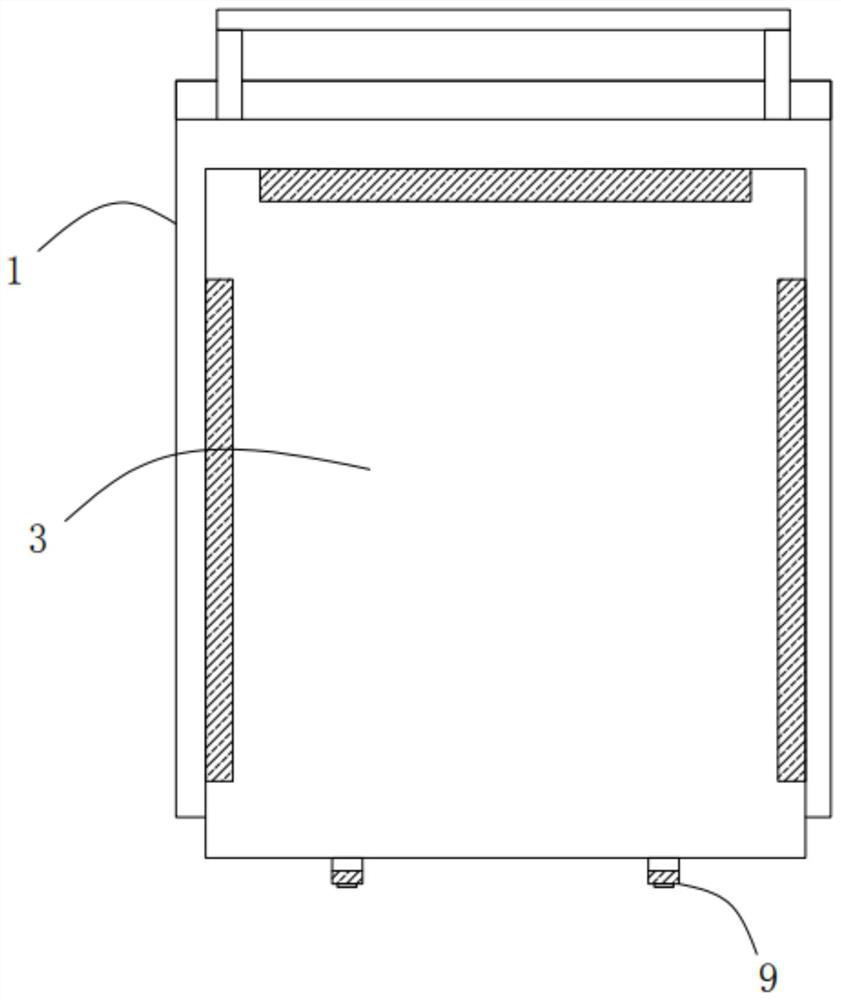

[0026] Please refer to Figure 1-4 , in the first embodiment of the present invention, the baking board in the PCB production process includes: a pallet 1, a handle is provided on the pallet 1; two guide rods 2, and the two guide rods 2 are fixed Installed on the top of the trolley 1; a slide plate 3, the slide plate 3 is slidably installed on the top of the two guide rods 2; two guide rail grooves 4, the two guide rail grooves 4 are opened on the top of the corresponding guide rod 2 The side of the guide rail groove 4 away from the handle of the trolley 1 is set as an opening; a plurality of rollers 5 are fixedly installed on the bottom of the slide plate 3, and a plurality of rollers 5 are respectively rolled and installed in the corresponding guide rail groove 4; two The first chamber 6, the two first chambers 6 are all opened on the slide plate 3; two slide bars 7, the two slide bars 7 are respectively movably installed in the corresponding first chamber 6, the slide bars ...

no. 2 example

[0037] Based on the oven plate in the PCB production process provided by the first embodiment of the present application, the second embodiment of the present application proposes another oven plate in the PCB production process. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0038] The second embodiment of the present invention will be further described below in conjunction with the drawings and implementation methods.

[0039] Please refer to Figure 5-6, the baking car plate in the PCB production process also includes a fixed block 10, the fixed block 10 is fixedly installed on the bottom of the slide plate 3, the bottom of the fixed block 10 is provided with a slot 11, and the top of the pallet car 1 is provided with a first round hole 12. An insertion rod 13 is slidably installed in the first round hole 12, and the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com