Placement layer theoretical thickness measuring and calculating method based on automatic tow placement technology

A technology of automatic laying and laying, which is applied in the field of theoretical thickness measurement of laying based on automatic laying technology, can solve problems such as large error and repeated trial and error, achieve accurate thickness, improve programming efficiency, and avoid actual laying. The effect of verification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for measuring and calculating the theoretical thickness of layers based on automatic wire laying technology, comprising the following steps:

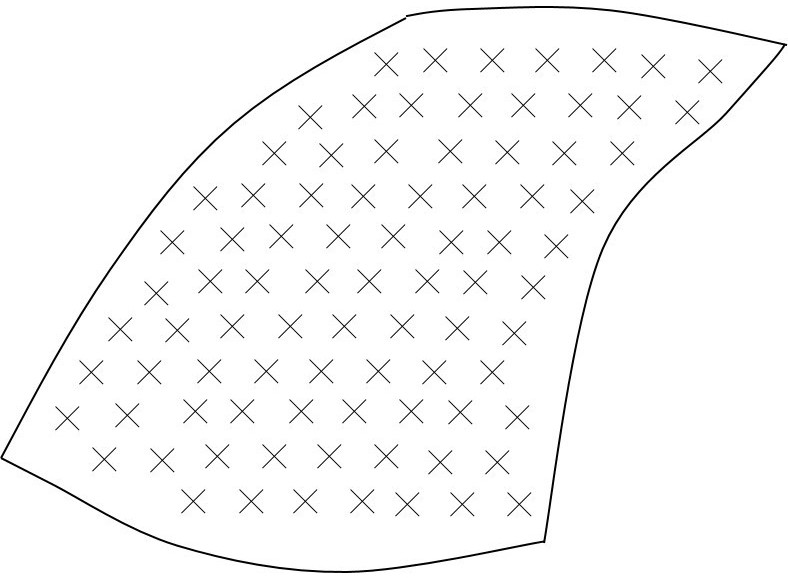

[0031] Step S1: Extract the molded surface of the part to be formed, and represent the molded surface with a point cloud, such as figure 1 , get points P1, P2, P3...Pn;

[0032] Step S2: According to the theoretical trajectory of the laying program, extract the centerlines L1S1, L1S2, L1S3...L1Sn of each tow on the first laying layer L1, and extract all centerline;

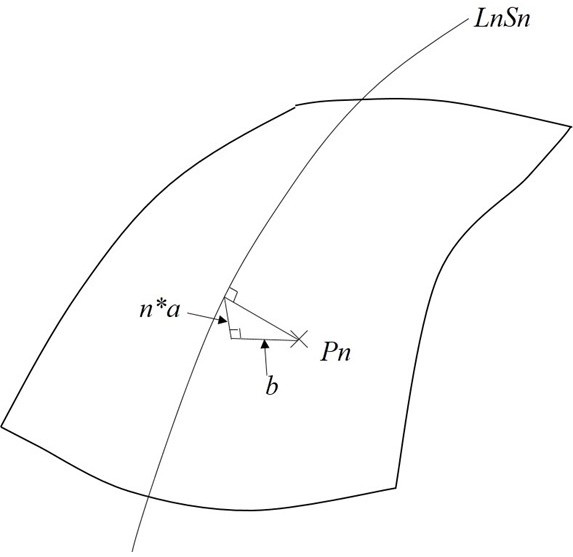

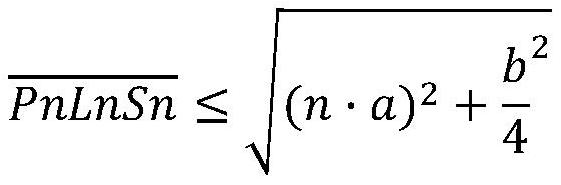

[0033] Step S3: For any layer Ln, find the perpendicular line between any point Pn in the point cloud and any center line LnSn on the layer, and the length of the perpendicular line

[0034] Step S4: if figure 2 , according to the calculated distance between the Pn point and the center line, determine whether the Pn point falls in the prepreg coverage area, and judge each point of the point cloud in turn, filter out the points that fall in the prepreg ...

Embodiment 2

[0038] A method for measuring and calculating the theoretical thickness of layers based on automatic wire laying technology, comprising the following steps:

[0039] Step S1: Extract the molded surface of the part to be formed, and represent the molded surface with a point cloud, such as figure 1 , to obtain points P1, P2, P3...Pn; when using point cloud to express the molding surface, the ply thickness information is obtained after mathematical calculation for each point, where the distance between two adjacent points is not greater than the specified value; the specified value is determined according to the width of the automatic wire laying material and the gap between the belts;

[0040] Step S2: According to the theoretical trajectory of the laying program, extract the centerlines L1S1, L1S2, L1S3...L1Sn of each tow on the first laying layer L1, and extract all centerline;

[0041] Step S3: For any layer Ln, find the perpendicular line between any point Pn in the point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com