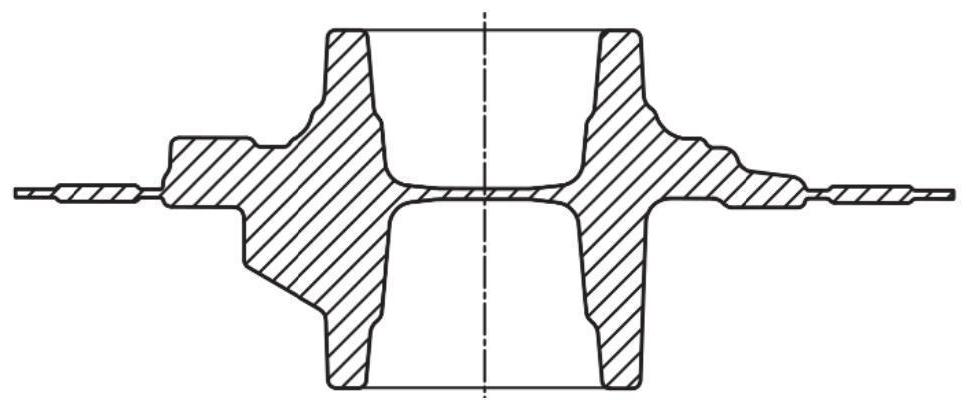

Forging die structure and forging method for disc type aluminum alloy automobile hub

A technology for automobile hubs and aluminum alloys, applied to wheels, manufacturing tools, vehicle parts, etc., can solve the problems of easy folding, difficult positioning, uneven metal distribution, etc., and achieve good stable positioning, prevent folding and full of defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

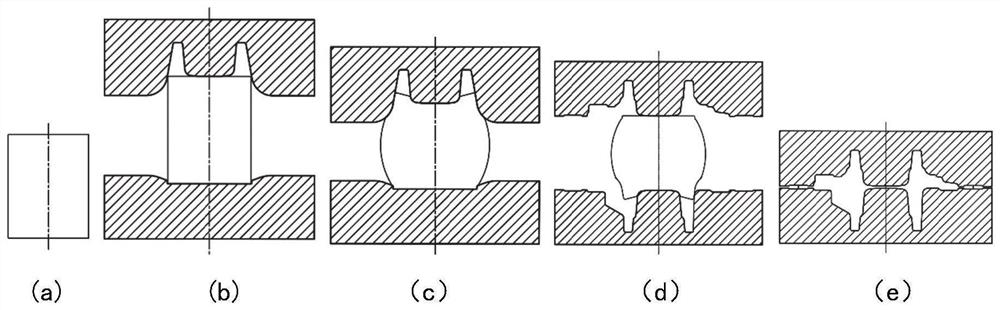

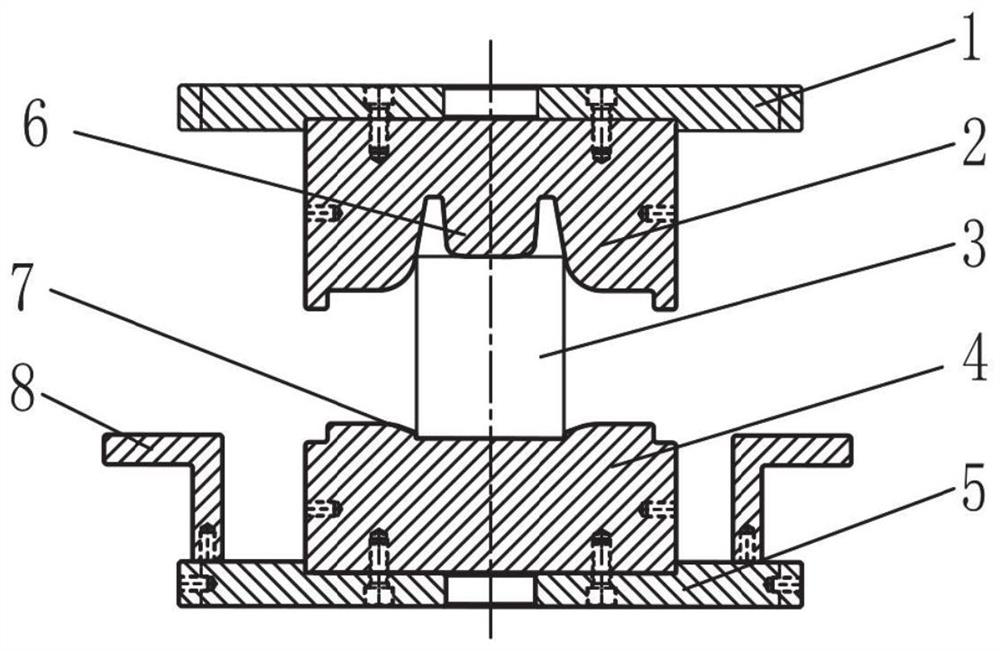

[0062] The blank is preheated to 500°C, the pre-forging die is 420°C, the diameter of the blank is 199mm, and the height is 244mm.

[0063] Place the preheated blank in the positioning groove of the lower die of the pre-forging die (align the pre-forging upper die with the pre-forging lower die, and use the positioning module to ensure that the center of the pre-forging upper die is always in line with the pre-forging die during movement) The center of the lower die is located on the same axis), the pre-forging upper die descends, and the descending speed is 18mm / s, and the pre-forging is carried out. When the reduction of the pre-forging upper die is 20% of the original height of the blank, the pre-forging ends;

[0064] Heat the final forging die to 425°C, rotate the pre-forging 180° (relative to the direction of pre-forging, turn it upside down, the top of the pre-forging is facing down), and place it on the core of the lower die of the final forging die, so that the pre-for...

Embodiment 2

[0074] Preheat the billet to 500°C, the pre-forging die is at 420°C, the diameter of the billet is 200mm, and the height is 250mm.

[0075] Place the preheated blank in the positioning groove of the pre-forging die of the pre-forging die (align the pre-forging die with the pre-forging die, use the positioning module to ensure that the center of the pre-forging die is in the process of movement Always on the same axis as the center of the pre-forging lower die), the pre-forging upper die descends at a speed of 21mm / s for pre-forging, when the reduction of the pre-forging upper die is 23% of the original height of the billet, End of pre-forging;

[0076] Heat the final forging die to 425°C, rotate the forging 180° (relative to the direction of the pre-forging, turn it upside down, the top of the pre-forging is facing down), and place it on the lower mold of the final forging die, so that the bottom of the pre-forging is in line with the final forging. The core contact of the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com