A sleep-improving enzymatic hydrolyzate rich in aromatic amino acids and preparation method thereof

An aromatic amino acid, sleep-improving technology, applied in food science, animal/human peptides, functions of food ingredients, etc., can solve the problems of complex processing methods, expensive operating instruments and equipment, unfavorable and widespread use, etc., and achieves simple and effective process conditions. , the effect of improving sleep disorders, improving sleep potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

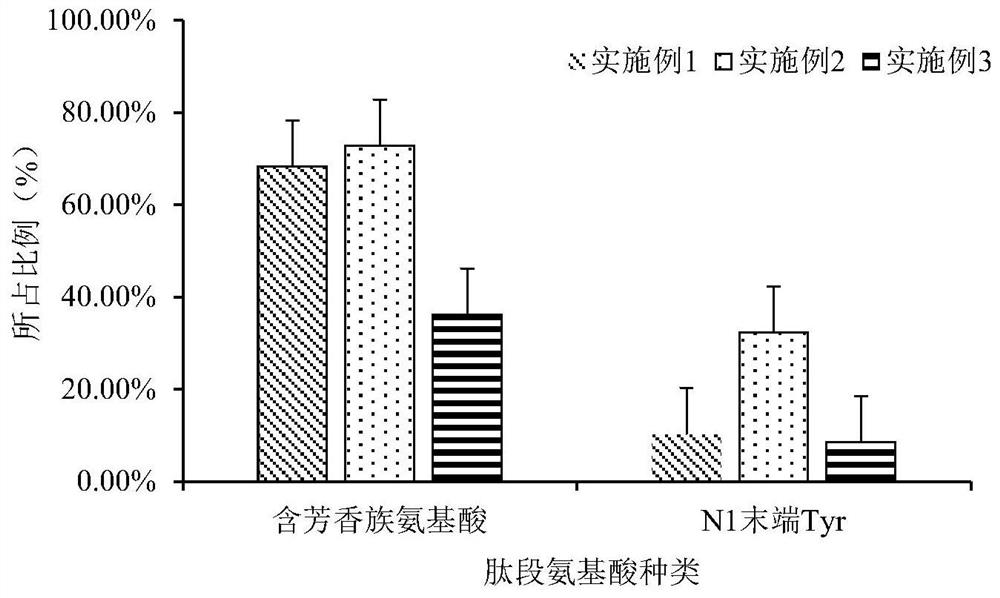

Examples

Embodiment 1

[0034] (1) Weigh and add casein and distilled water respectively according to the ratio of parts by mass to 1:8, start the pretreatment, heat up to 35°C, stir and dissolve at a constant speed of 20HZ to obtain a casein dispersion.

[0035] (2) Add edible alkali to the above-mentioned casein dispersion liquid to adjust pH to 7, stir the dispersion liquid until there are basically no large particles, add 1‰ of trypsin (according to the mass of raw material casein), and enzymatically hydrolyze the liquid at 37°C for 4 hours to obtain The enzymolysis solution was rapidly heated to 85-95°C for 10-15min to inactivate the enzyme. After inactivating the enzyme, the enzymatic hydrolysis solution was cooled to room temperature, and the macromolecular precipitate was removed by centrifugation at 4°C and 9000g.

[0036] (3) Immediately take the supernatant and concentrate until the solid content reaches 30%, the inlet air temperature is 210°C, the outlet air temperature is 120°C, and the ...

Embodiment 2

[0038](1) Weighing and adding casein and distilled water in a ratio of 1:10 in parts by mass, starting pretreatment, heating to 40° C., stirring and dissolving at a constant speed of 40 Hz, to prepare a casein dispersion.

[0039] (2) Add edible alkali to the above casein dispersion to adjust pH to 7.5, stir the dispersion until there are basically no large particles, add 2‰ papain (based on the mass of raw casein), enzymolysis at 55°C for 1 hour, and kill the enzyme After cooling to room temperature, 5‰ of trypsin (based on the mass of raw material casein) was added, and the enzyme was hydrolyzed at 37°C for 1.5h to obtain a secondary enzymatic hydrolysis solution. After inactivating the enzyme, the enzymatic hydrolysis solution was cooled to room temperature, and the macromolecular precipitate was removed by centrifugation at 4°C and 10,000 g.

[0040] (3) Immediately take the supernatant and concentrate until the solid content reaches 35%, the inlet air temperature is 185°C...

Embodiment 3

[0042] (1) The casein and distilled water are respectively weighed and added in a ratio of 1:12 in parts by mass, and the casein dispersion is directly prepared without pretreatment.

[0043] (2) Add edible alkali to the above casein dispersion to adjust the pH to 8, stir the dispersion until there are basically no large particles, add 2‰ of alkaline protease Alcalase (based on the mass of raw material casein), and enzymolysis at 55°C for 1h , get the enzymolysis solution, inactivate the enzyme and cool it to room temperature, then add 8‰ papain (according to the mass of the raw material casein), enzymolysis at pH 7, 55°C for 2h, then rapidly heat up to 85-95°C for 10-15min to inactivate the enzyme. After inactivating the enzyme, the enzymatic hydrolysis solution was cooled to room temperature, and the macromolecular precipitate was removed by centrifugation at 10 °C and 8000 g.

[0044] (3) Immediately take the supernatant and concentrate until the solid content reaches 20%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com