Novel hydraulic and pneumatic composite control cylinder of hydraulic hammer and sealing form

A hydro-pneumatic and composite control technology, which can be used in fluid pressure actuating devices, sheet pile walls, buildings, etc., and can solve the problems of large volume and weight of pile hammers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the embodiments described in the accompanying drawings.

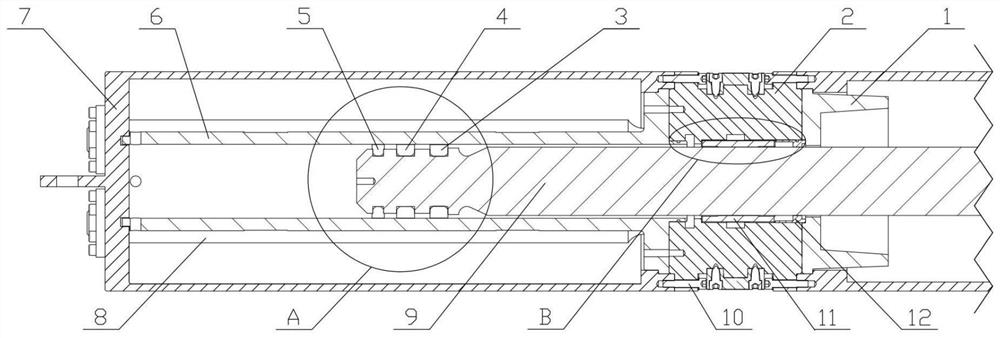

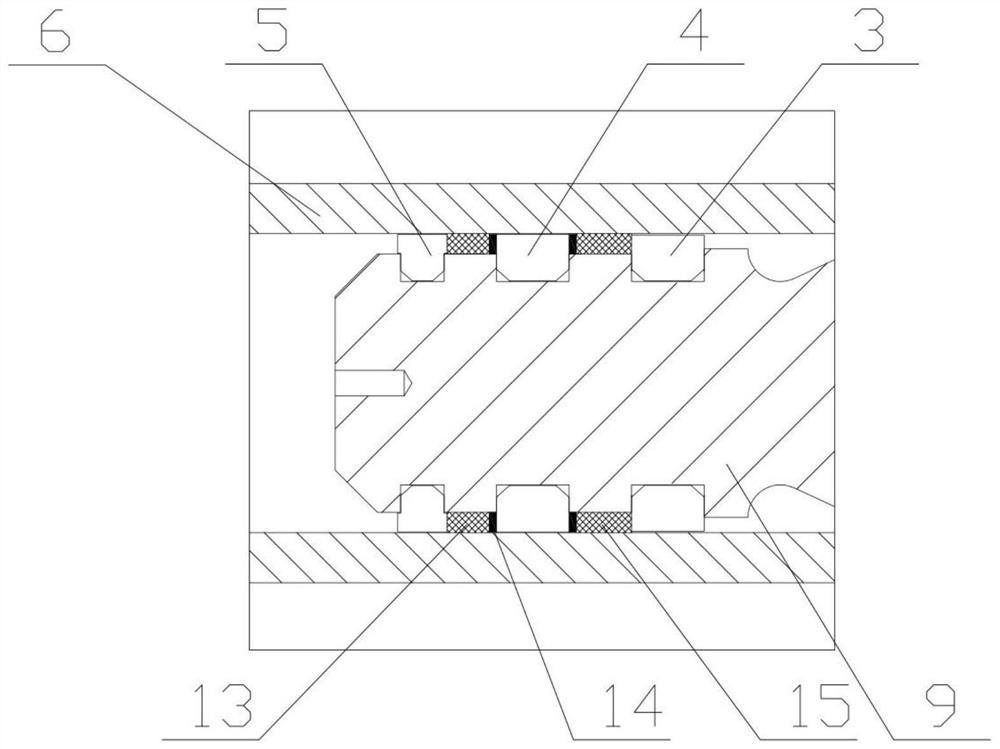

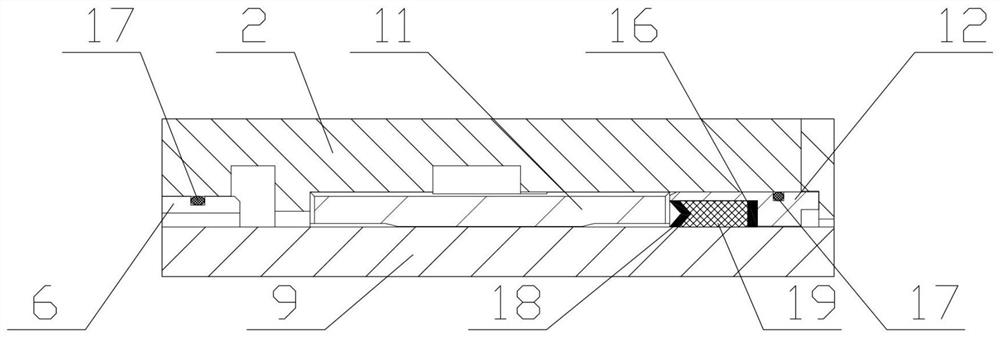

[0022] figure 1 It is a structural schematic diagram of the main part of an embodiment of the present invention. As shown in the figure, the new hydraulic hammer hydraulic pneumatic compound control cylinder and sealing form of the present invention structurally include a top stroke limiter 1, an integrated combined valve block 2, a piston ring 3, a compression ring 4, a fixed ring 5, and a cylinder body ( Integrated hydraulic and pneumatic composite control cylinder) 6, outer shell 7, accumulator 8, piston rod 9, socket head screw 10, piston rod bearing bush 11, piston rod sealing box 12. Piston rod 9 is connected with the hammer body of piling hammer.

[0023] The integrated hydraulic-pneumatic compound control cylinder is the key part of the hydraulic-pneumatic compound piling hammer. The sealed space between the cylinder body 6 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com