High-altitude large-span cantilever structure construction platform and method

A technology of large-span cantilever and construction platform, which is applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., to achieve the effects of convenient construction and installation, avoiding cross operations, and reducing the risk of high-altitude operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a high-altitude large-span cantilever structure construction platform, including: a concrete structure, a column embedded in the concrete structure, a parallel chord truss arranged on the column, an upper chord secondary beam arranged on the upper chord of the truss, and an upper chord secondary beam arranged on the upper chord of the truss. The lower chord secondary beam of the lower chord of the truss, the profiled plate or supporting formwork arranged on the upper chord secondary beam.

[0032] This embodiment also provides a construction method for the construction platform of the above-mentioned high-altitude large-span cantilevered structure, including the following steps:

[0033] 1) Construct the concrete base module first, and install the column on the concrete base module after the concrete base module reaches the design strength;

[0034] 2) After the column is installed, the concrete base module is constructed on the concrete base mo...

Embodiment 2

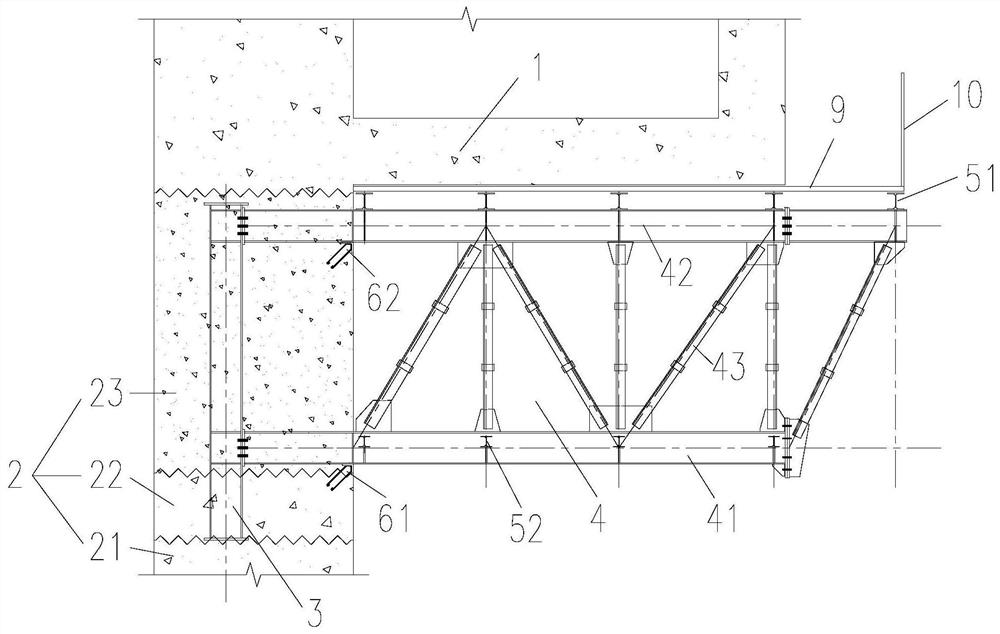

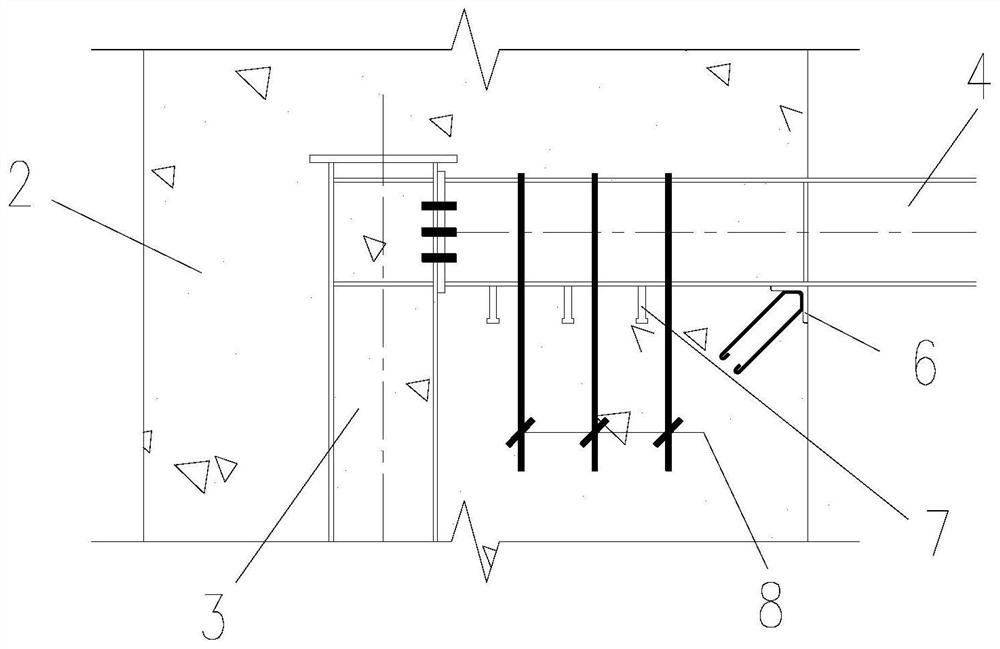

[0041] Such as figure 1 , 2 As shown, the present embodiment provides a construction platform for a high-altitude large-span cantilever structure 1, comprising: a concrete structure 2, a column 3 pre-embedded in the concrete structure 2, a parallel chord truss 4 arranged on the column 3, a truss arranged on the truss 4 The upper chord secondary beam 51 of the upper chord 42 , the lower chord secondary beam 52 arranged on the lower chord 41 of the truss 4 , the profiled plate 9 or the supporting formwork arranged on the upper chord secondary beam 51 . The construction platform is set under the high-altitude long-span cantilever structure 1 .

[0042] Specifically, the column 3 in this embodiment is a wide-flange H-shaped steel column. The parallel chord truss 4 includes: a lower chord 41 , an upper chord 42 , and a web 43 , the upper chord 42 and the lower chord 41 are parallel to each other, and the upper chord 42 is connected to the lower chord 41 through the web 43 . Spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com