Transverse and longitudinal integrated non-power framework device with temperature-measurable axle boxes

An integrated, non-powered technology, which is applied in the axlebox installation, axlebox, bogie, etc., can solve problems such as failure to meet the installation position and vibration reduction indicators, cumbersome disassembly and maintenance procedures, and influence on layout space and structural form. Achieve the effect of exempting the design and manufacture of complex special positioning tooling and the cumbersome use process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings.

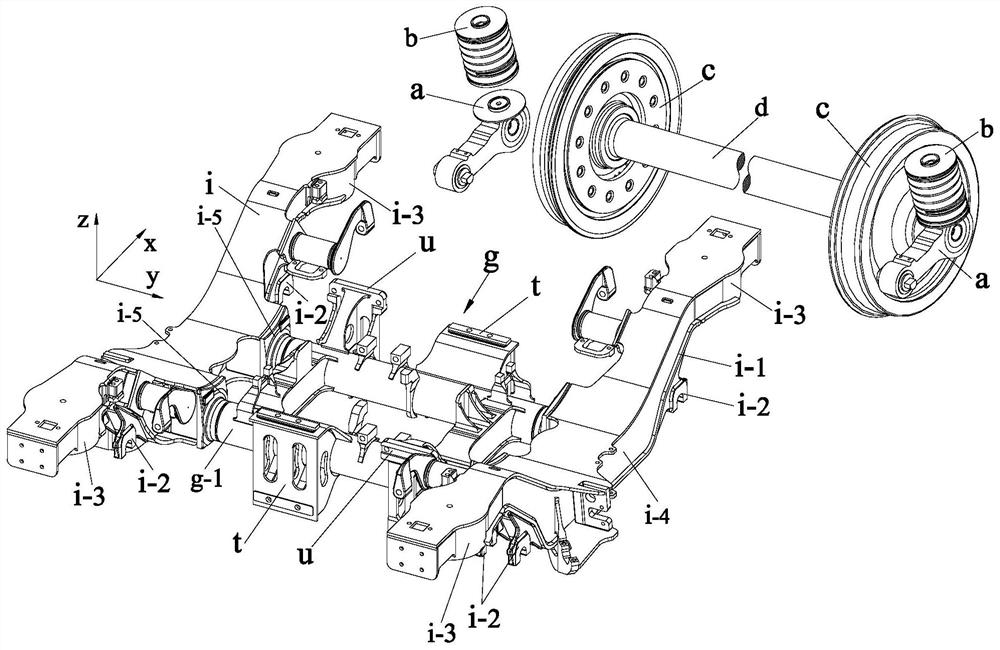

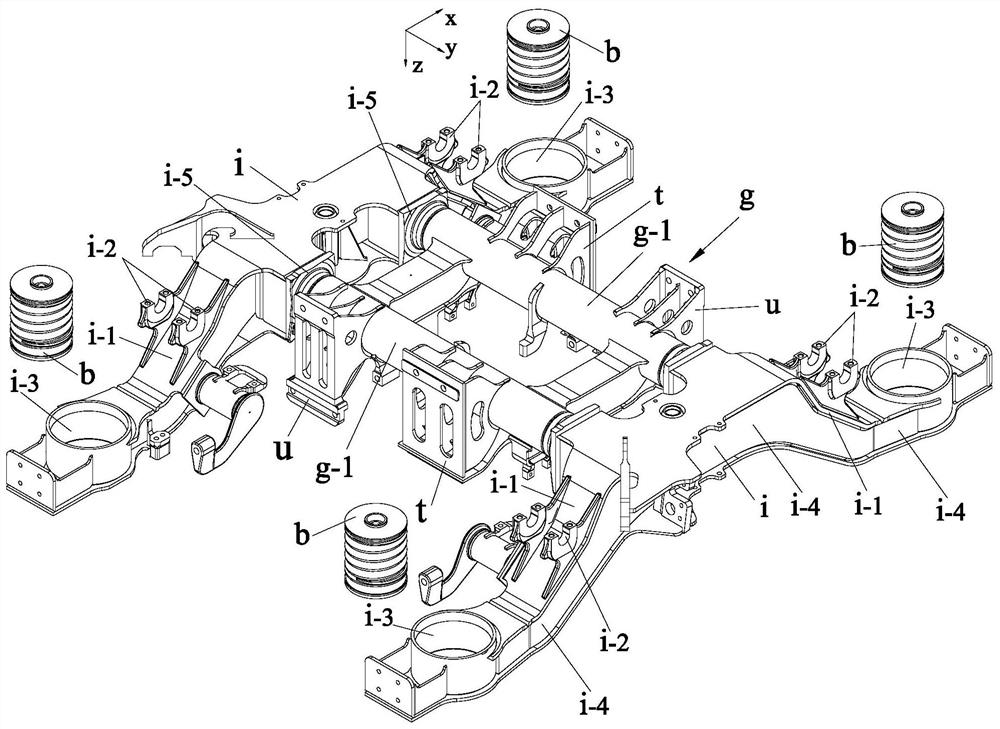

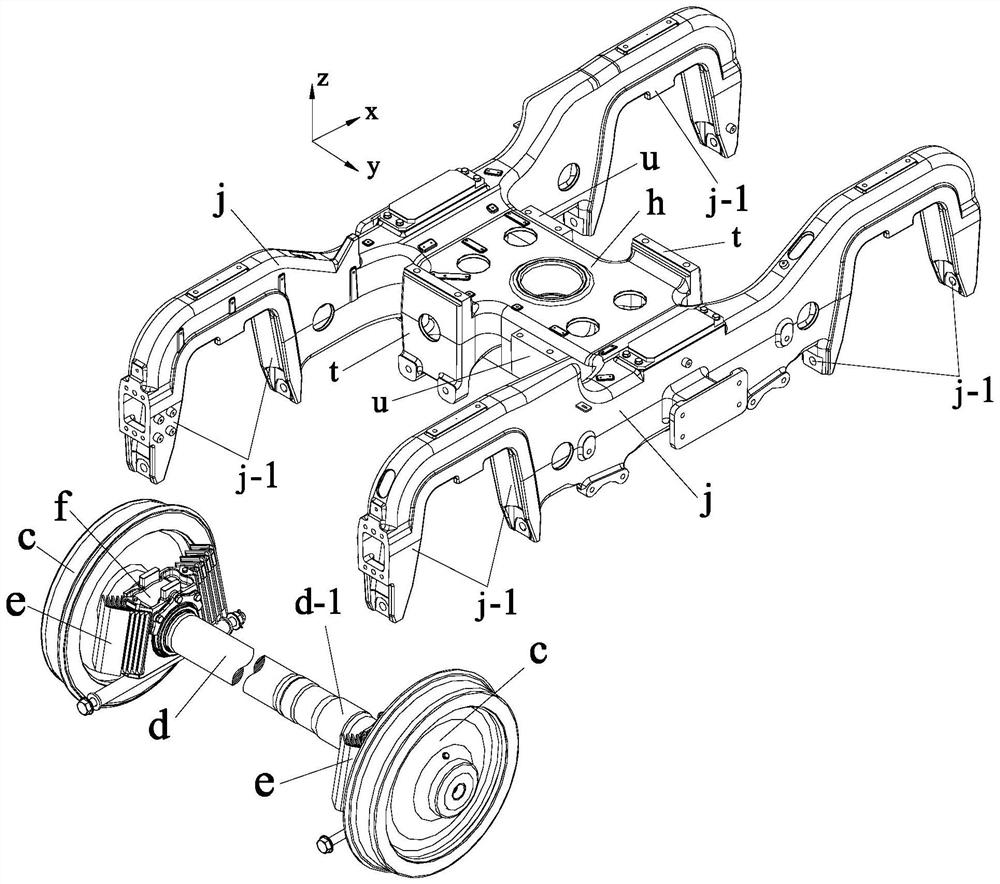

[0042] like Figure 4 to Figure 12 As shown, the horizontal and vertical integrated non-dynamic frame device with a temperature-measurable axle box of the present invention includes: a horizontal and vertical integrated interconnecting frame and four annular vibration damping axle boxes; the horizontal and vertical integrated interconnecting frame includes two horizontal and vertical integrated interconnecting frames. Longitudinal integrated frame, each horizontal and vertical integrated frame includes integrated side beam 1-1 and integrated beam 1-2; The middle side beam section 1-1-1 at the low position and the cantilever section 1-1-2 of the bird-wing-shaped side beam that are symmetrically fixed to both ends of the middle section of the side beam 1-1-1, and the cantilever section 1-1- 2 It is formed by connecting an upward tilting section and a horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com