Efficient mixing device for civil engineering

A technology of mixing device and civil engineering, which is applied in mixing operation control device, clay preparation device, mixing operation control and other directions, can solve the problems of proportioning, accumulation of concrete materials, insufficient mixing and mixing of materials, etc., and achieves convenient use and improved uniformity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

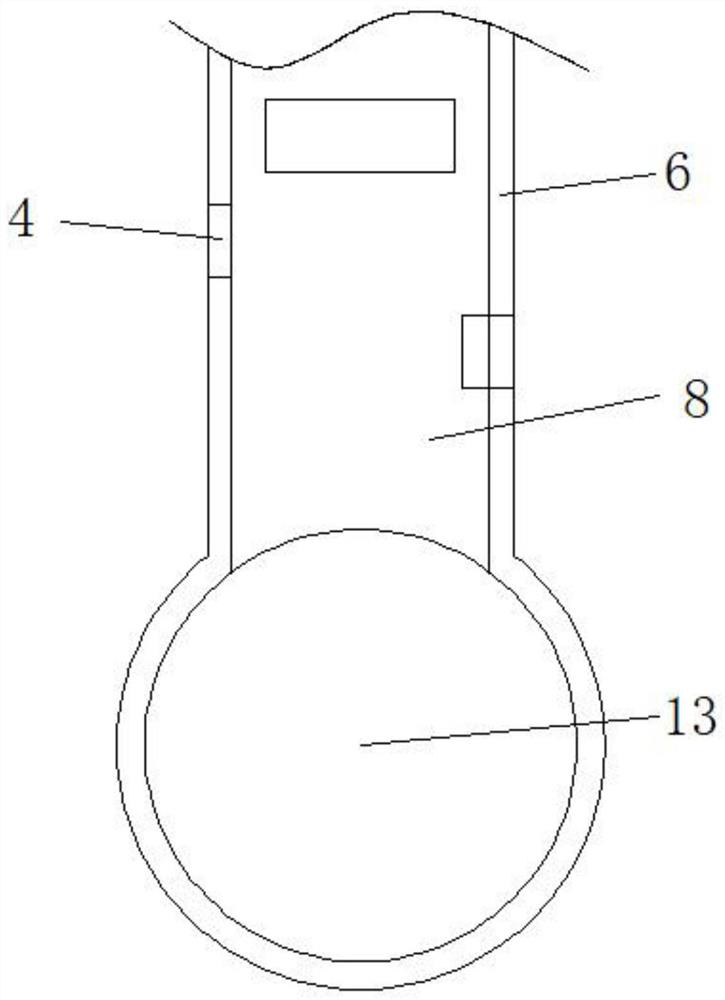

[0029] Such as Figure 1-7The shown high-efficiency mixing device for civil engineering includes a mixing cylinder 2, a fixing seat 3 and a connecting cylinder 6. A second connecting chamber 14 is vertically opened at the center of the fixing seat 3, and the outside of the second connecting chamber 14 The inside of the fixed seat 3 is provided with three storage chambers 5 at equal intervals with the second connection chamber 14 as the center of the circle, and the first feed port 9 is provided on the inner wall between the second connection chamber 14 and the storage chamber 5, and the second The upper and lower ends of the connection chamber 14 are equipped with a connection cylinder 6 through bearings, and a material guide chamber 8 is provided at the middle position of the connection cylinder 6, and a second ring gear 19 is welded on the inner wall of the material guide chamber 8 at the top of the connection cylinder 6. And the second ring gear 19 has teeth uniformly distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com