Automatic metal pipe bending device for mechanical equipment machining

A technology of mechanical equipment and bending device, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of bending degree limited by working height and low bending efficiency, and achieve improved bending efficiency, simple and reasonable structure, Quick and easy effects to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below, in conjunction with accompanying drawing and specific embodiment, the invention is further described:

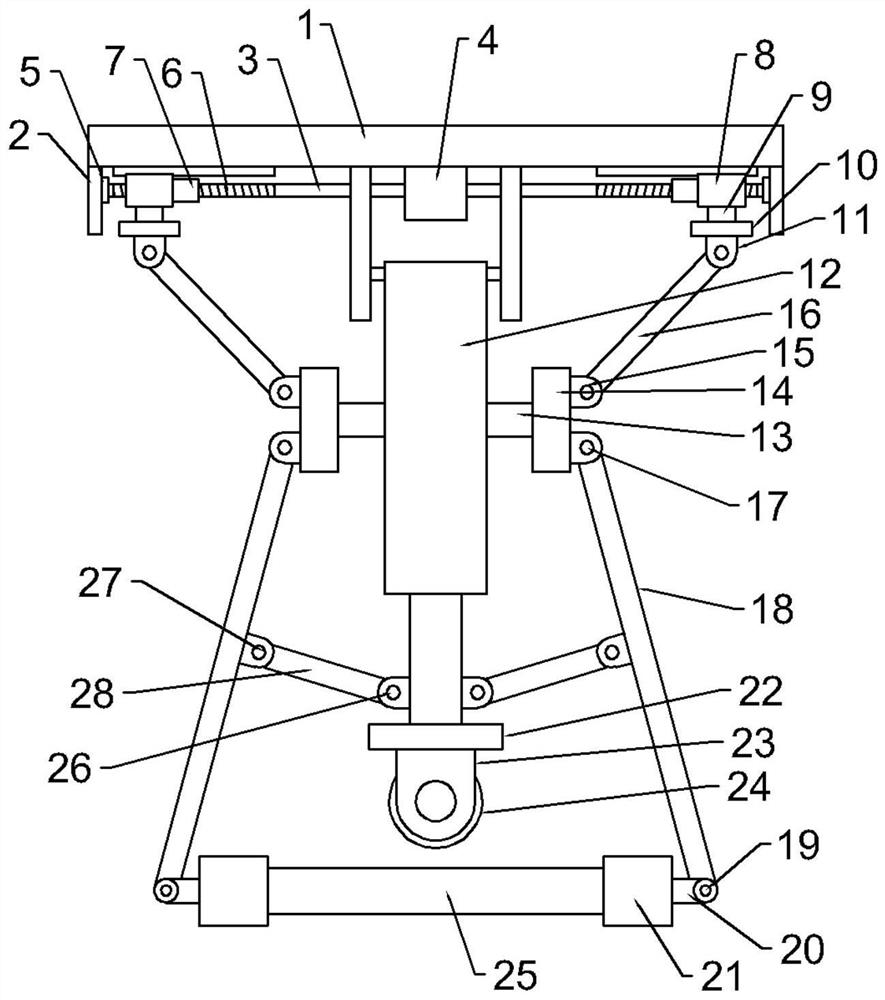

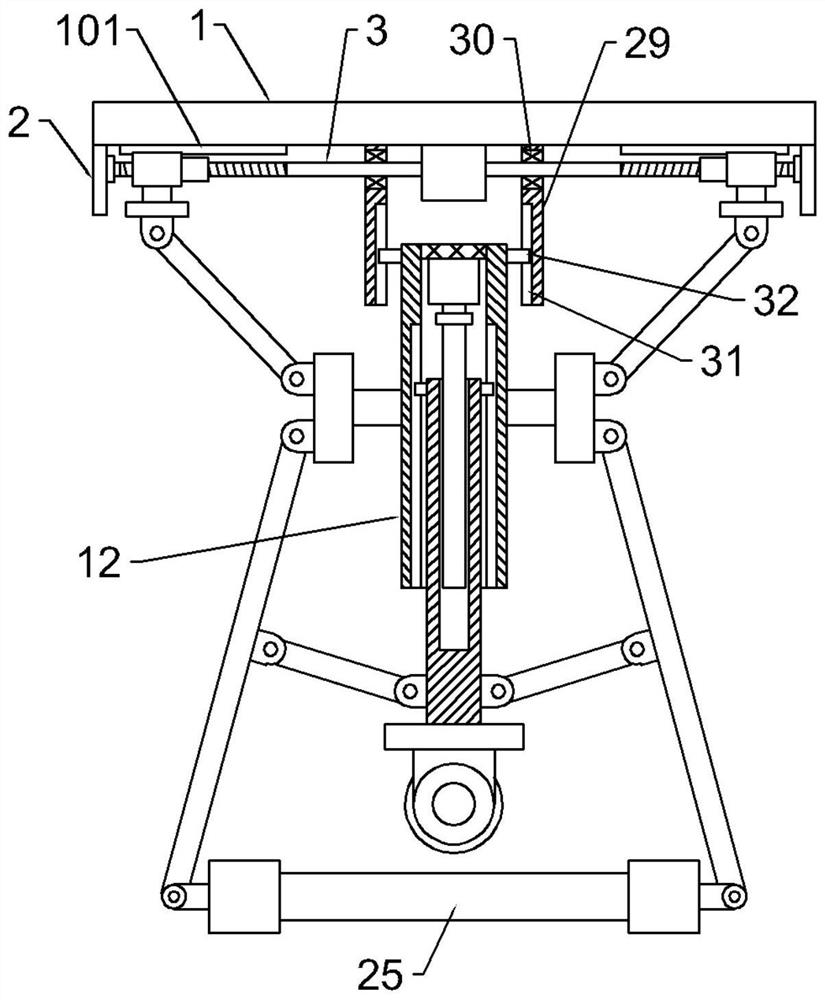

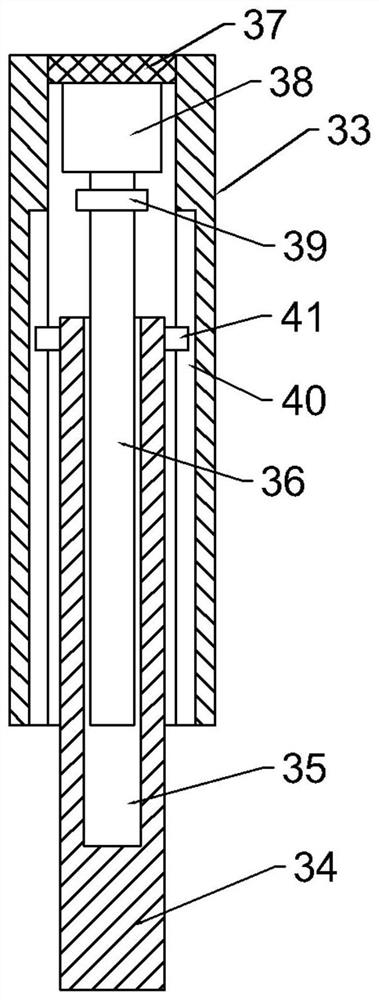

[0026] see Figure 1-5According to an embodiment of the present invention, an automatic bending device for metal pipes for mechanical equipment processing includes a fixed plate 1, and fixed blocks 2 are fixedly installed on the bottom of the fixed plate 1 along the two ends of its length direction, two An adjustment shaft 3 is arranged between the fixed blocks 2, a power box 4 is installed in the middle of the adjustment shaft 3, and the power box 4 is fixedly installed on the bottom center of the fixed plate 1, and the two ends of the adjustment shaft 3 are provided with threaded parts 6. The thread direction on the threaded part 6 at both ends is oppositely set, and the screw sleeve 7 is installed on the threaded part 6. The end of the screw sleeve 7 away from the center of the adjustment shaft 3 is fixedly linked with a moving sleeve 8, and the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com