Flour screening machine for making pastries

A screening machine and flour technology, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of increasing the burden on the staff, reducing the work efficiency, and the screening is not thorough enough, so as to avoid the blockage of the screen holes, improve the work efficiency, The effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

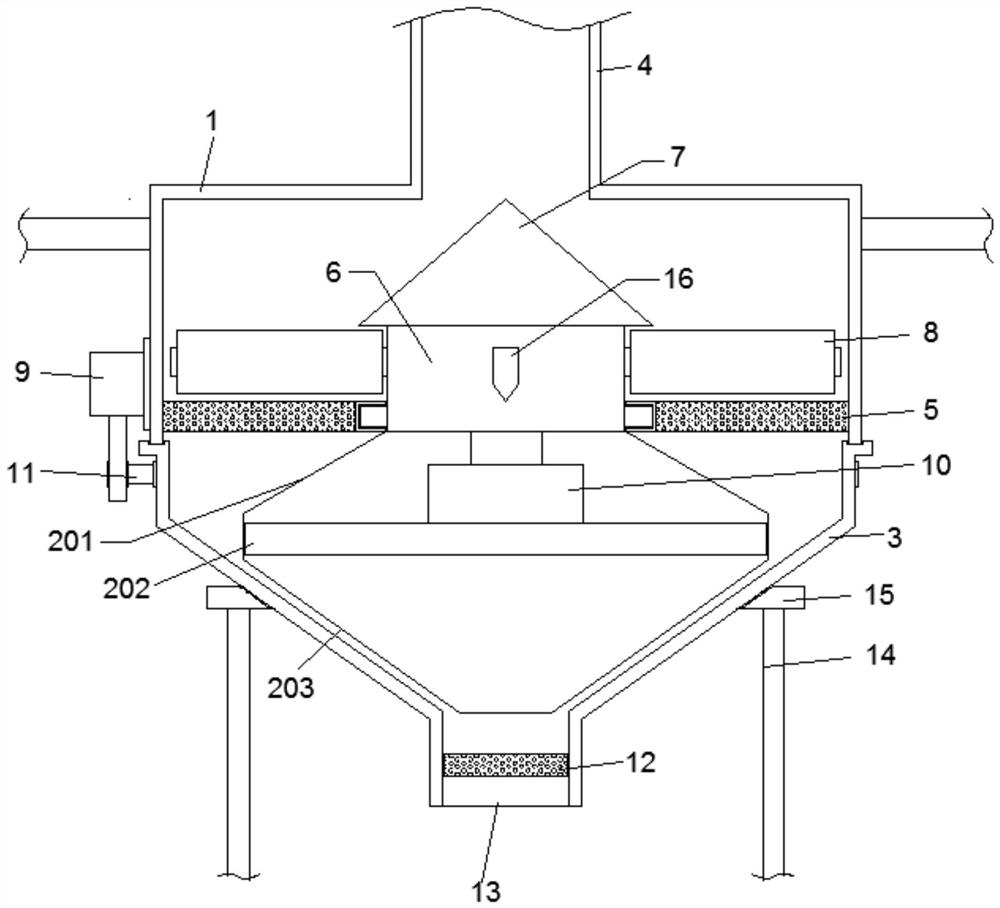

[0034] Such as figure 1 , Figure 4 ~ Figure 7 As shown, a pastry flour screening machine includes a working cover 1, a grinding cylinder 2 and a grinding cover 3. The working cover 1 is cylindrical. The upper side of the working cover 1 is vertically provided with a conveying pipe 4, and a No. 1 sieve is arranged inside. The sub-plate 5 is connected with a No. 1 motor 9 on the outer wall, and a circular through hole is provided at the center of the No. 1 screening plate 5. An annular chute is provided on the side wall of the through hole, and a movable card is provided at the lower part of the connecting column 6. The annular plate 601 combined in the annular chute, the connecting column 6 can do circular rotation in the through hole, the upper side of the connecting column 6 is provided with a conical diverter block 7, and the side wall is evenly connected with a rolling roller 8, wherein The splitter block 7 is located directly below the conveying pipe 4, and the rolling r...

Embodiment 2

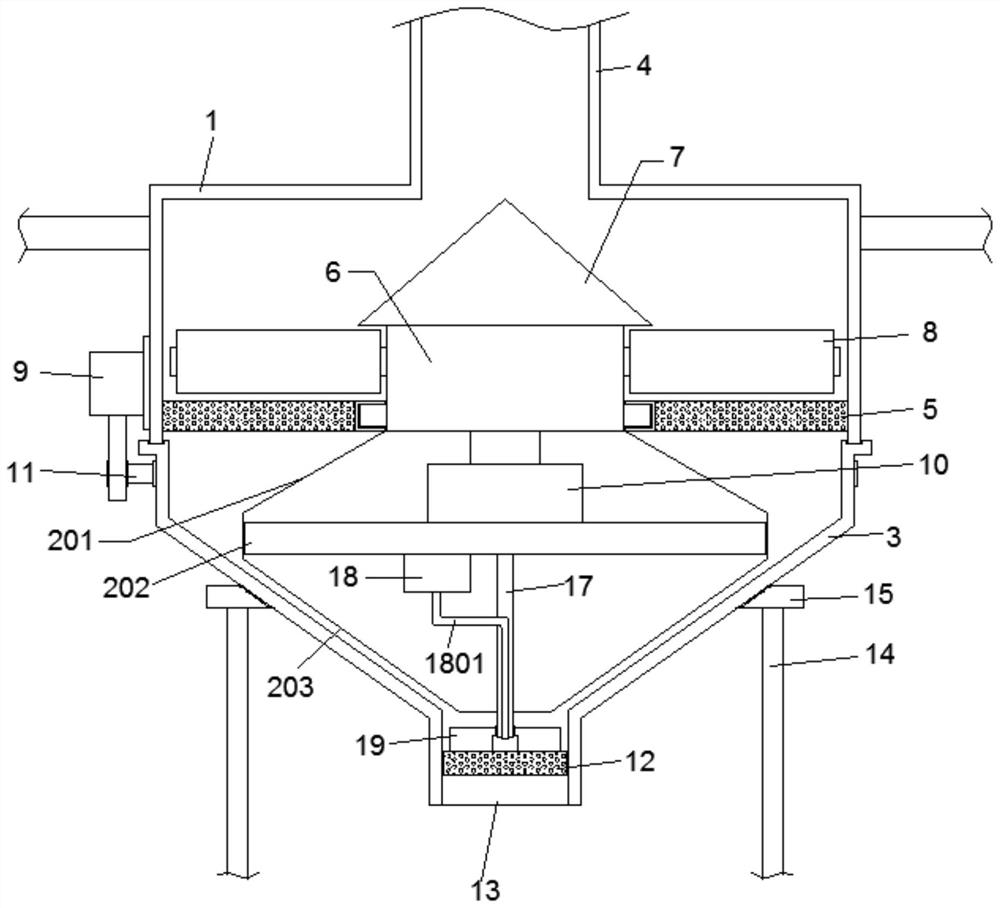

[0039] Such as figure 2 , Figure 4 ~ Figure 6 and Figure 8 As shown, the flour on the No. 1 sieve plate 5 easily sticks to the No. 1 sieve plate 5 in the process of being rolled, causing agglomeration or protrusions, thereby affecting the effect of the rolling roller 8. To avoid this phenomenon, a No. 1 scraper 16 can be evenly arranged on the side wall of the connecting column 6. The No. 1 scraper 16 is arranged crosswise with the rolling roller 8. The bottom surface of the No. 1 scraper 16 is connected to the top of the No. side contact. During the rotation of the connecting column 6, the No. 1 scraper 16 also rotates together, which can remove agglomerated or raised flour, and ensure the smoothness of the upper side of the No. 1 sieve plate 5, which is beneficial to the rolling roller 8 on the flour. crushed.

Embodiment 3

[0041] Such as image 3 , Figure 4 ~ Figure 6As shown, after the flour passes through the grinding layer, it will fall on the No. 2 sieve plate 12 for secondary sieving. In order to speed up the sieving of flour, a fixed rod 17 and a blower 18 are provided on the lower side of the cylindrical block 202, wherein The bottom end of the fixed 17 is set through the bottom surface of the lower round table 203, and the No. 2 scraper 19 is uniformly arranged, and the No. 2 scraper 19 is in contact with the upper side of the No. 2 screening plate 12. The blower 18 is connected with a conduit 1801, and the conduit 1801 Distributed along the inside of the fixed rod 17 , and the nozzle of the conduit 1801 runs through the bottom surface of the fixed rod 17 . Start the blower 18 synchronously with the No. 1 motor 9 and the No. 2 motor 10, and the No. 2 sieve plate 12 will rotate together with the grinding cover 3. At this time, the No. 2 scraper 19 plays a role in stirring, accelerating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com