Endoscope tip and endoscope

An endoscope and tip technology, which is applied in the field of medical endoscopes, can solve the problems of small lighting output area, affecting assembly efficiency, collision of the light source of the tip cover, etc., so as to improve production efficiency and yield, improve lighting efficiency and life. , the effect of increasing the lighting output angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

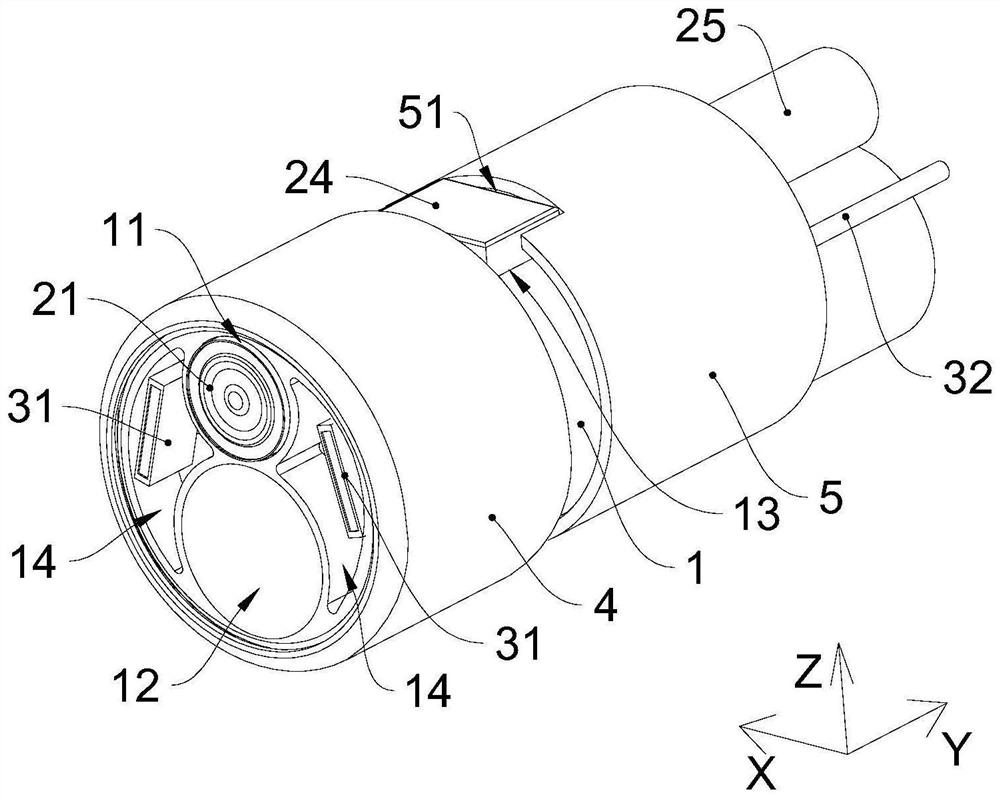

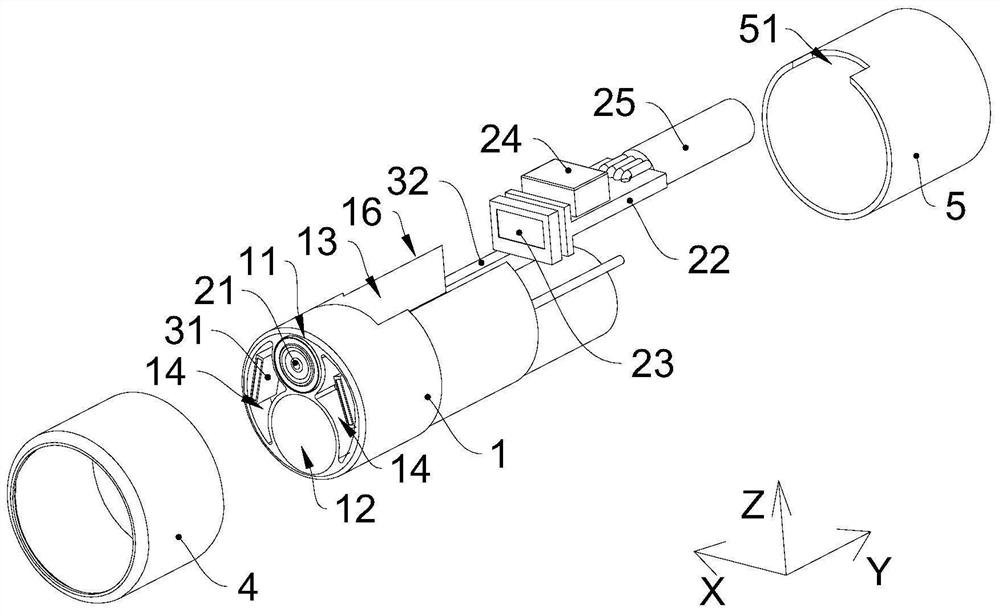

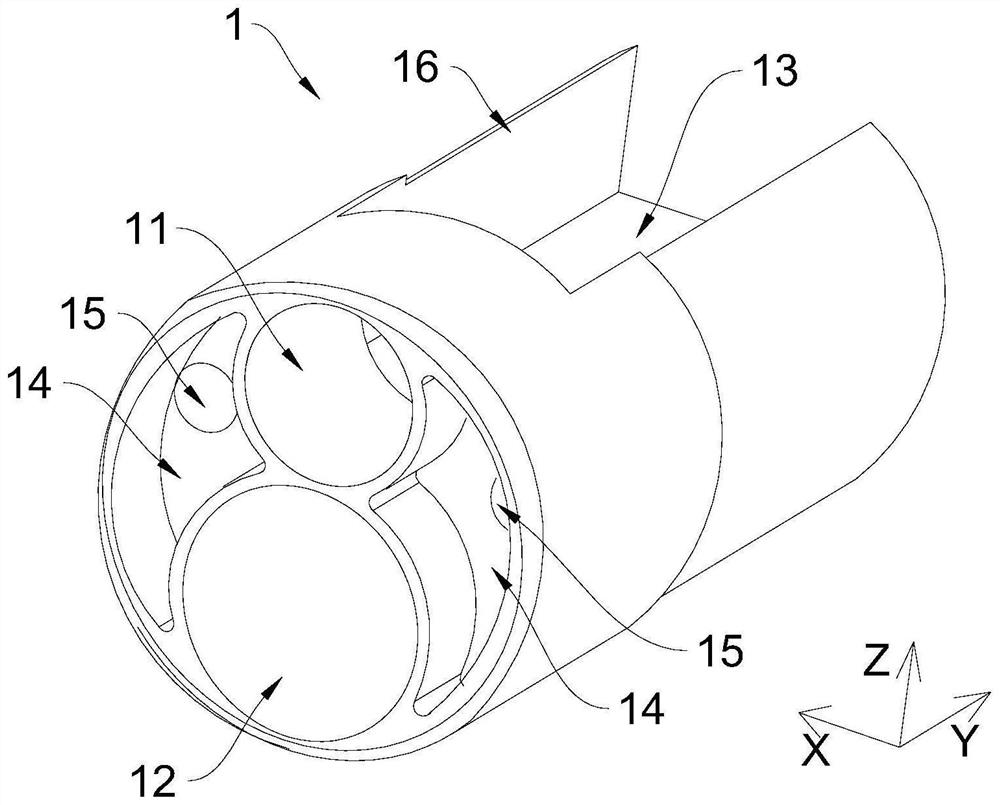

[0022] Endoscope tip embodiment

[0023] see figure 1 and figure 2 , The tip end of the endoscope includes a mounting base 1, a camera assembly, a lighting assembly, an insulating protective sleeve 4 and a snake joint sleeve 5. For the convenience of description, the axial direction of the tip of the endoscope is set as the Y direction, the first radial direction of the tip of the endoscope is set as the X direction, and the second direction perpendicular to the first radial direction of the tip of the endoscope is The radial direction is set to the Z direction. Both the camera assembly and the lighting assembly are arranged on the mounting base 1, and the insulating protective sleeve 4 and the snake bone connecting sleeve 5 are respectively sleeved on both ends of the mounting base 1 in the Y direction. The distance between the insulating protective sleeve 4 and the snake bone connecting sleeve 5 is preset. Set distance.

[0024] The camera assembly includes a lens 21 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com