Crushing and mixing device for producing vegetable cheese and use method thereof

A technology for mixing devices and vegetables, which is applied to mixers with rotating stirring devices, mixers, chemical instruments and methods, etc., can solve the problems of low processing efficiency, complicated operation, and many process equipment, so as to improve efficiency and improve The effect of mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

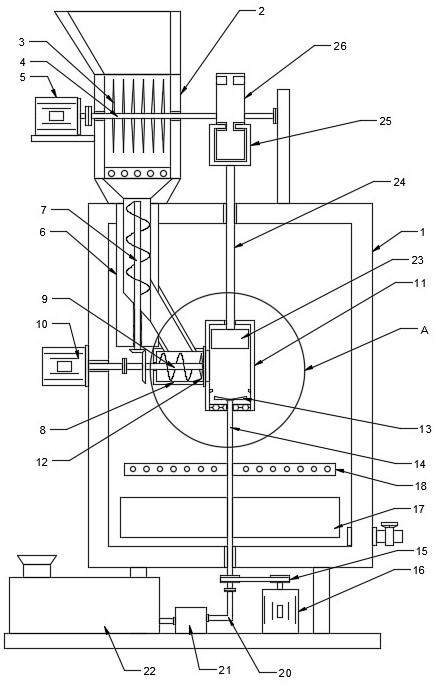

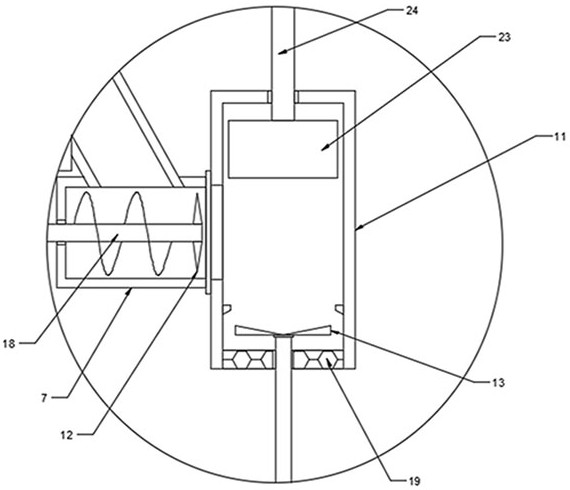

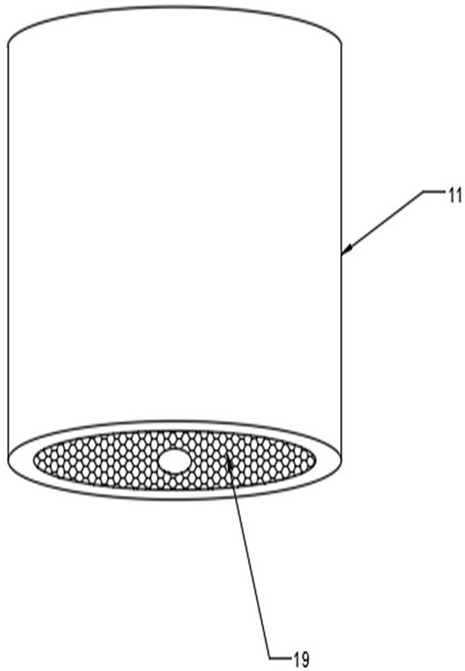

[0022] see Figure 1-3 , in an embodiment of the present invention, a crushing and mixing device for producing vegetable cheese includes a mixing box 1; a feeding hopper 2 is arranged above the mixing box 1, and the feeding hopper 2 is fixedly connected to the mixing box 1; the feeding hopper 2 is provided with a crushing blade group 3, the crushing blade group 3 is fixedly connected with a through shaft 4, the through shaft 4 extends to the left side of the feeding hopper 2 and is connected with a first motor 5 through a coupling, the first motor 5 is connected to the The side wall of the feeding hopper 2 is fixedly connected; specifically, put the vegetable raw material into the feeding hopper 1, start the first motor 5, and the first motor 5 drives the through shaft 4 to rotate, and then drives the crushing blade group 3 to rotate, and the vegetable raw material is preliminarily processed. broken.

[0023] The lower part of the feeding hopper 2 is connected with a feeding ...

Embodiment 2

[0032] The difference between this embodiment and Embodiment 1 is that a pressing block 23 is embedded in the juice extracting cylinder 11, and the pressing block 23 is fixedly connected with a lifting rod 24, and the lifting rod 24 runs through the juice squeezing cylinder 11 and slides with the juice squeezing cylinder 11 connection; the upper end of the elevating rod 24 is fixedly connected with a clamping frame 25, the clamping frame 25 is clamped with an eccentric groove plate 26, and the eccentric groove plate 26 is provided with an eccentric circular groove; the eccentric groove plate 26 is fixedly connected with the through shaft 4 , the penetrating shaft 4 drives the eccentric groove plate 26 to rotate, the eccentric groove plate 26 drives the clamping frame 25 to move up and down, the clamping frame 25 drives the pressing block 23 to move up and down through the lifting rod 24, squeezes the vegetable raw materials, and improves the juicing and crushing efficiency .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com