Multi-speed planetary transmission for a vehicle with at least one electric machine

A transmission mechanism and planetary gear technology, applied in the field of multi-speed planetary transmission mechanism, can solve the problem of expensive switching and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

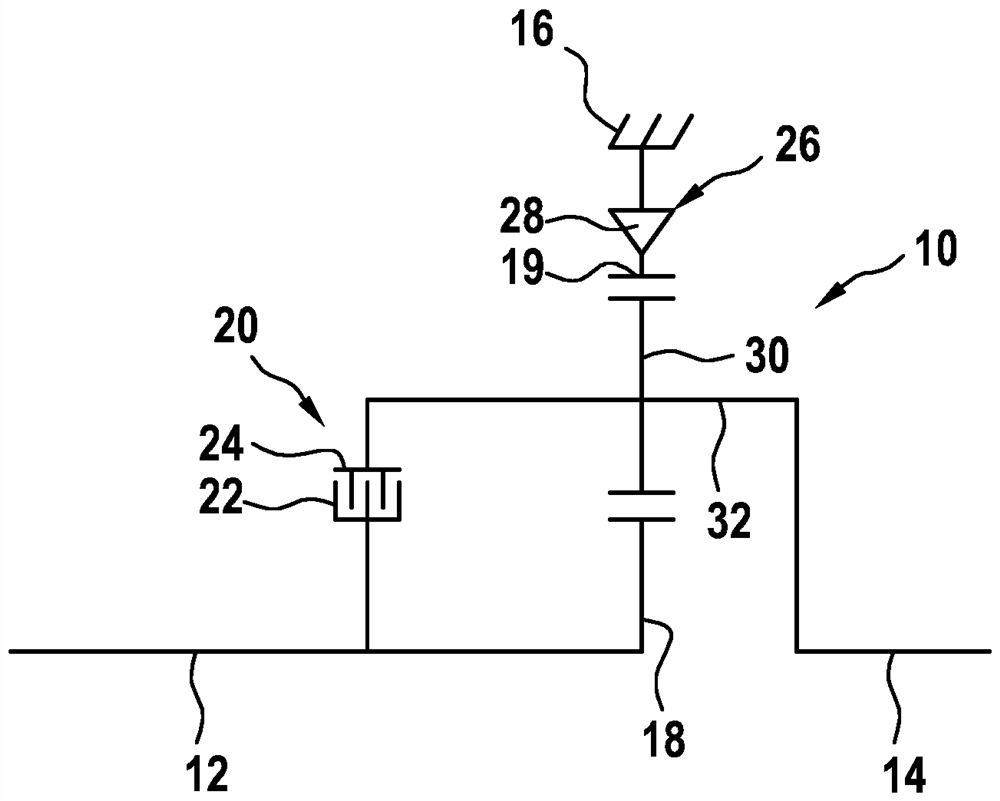

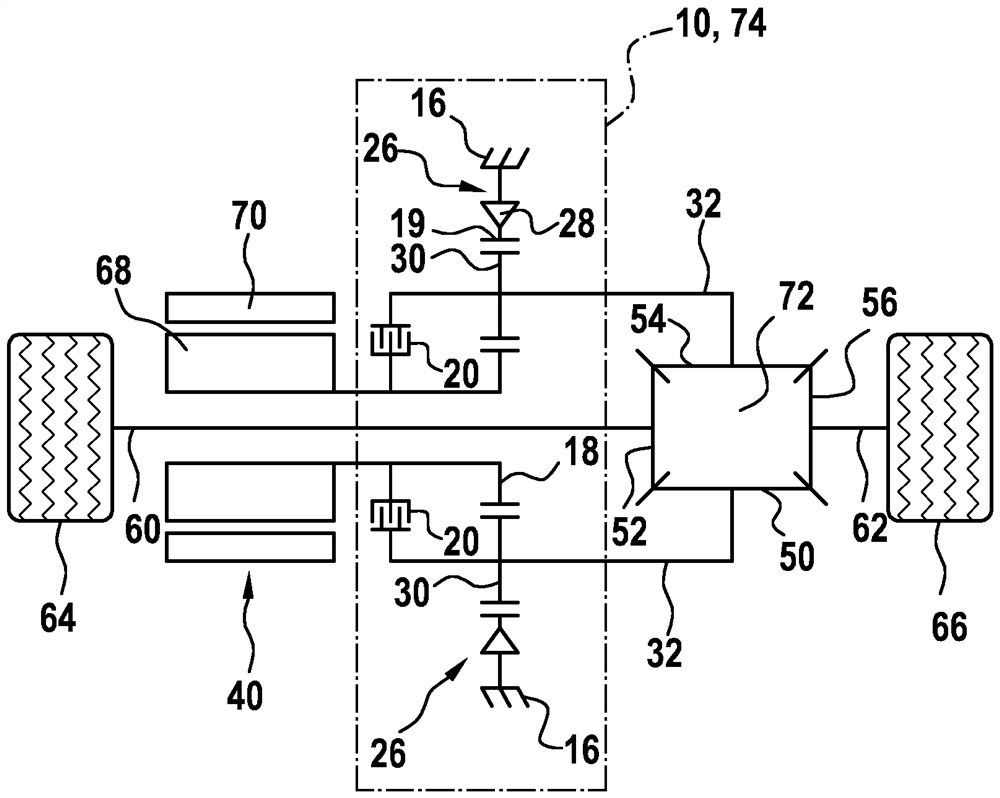

[0019] according to figure 1 The illustration in FIG. 2 shows a multi-speed planetary transmission 10 which is received between a drive shaft 12 and an output shaft 14 .

[0020] The multi-speed planetary gear 10 is accommodated in a housing 16 . A sun gear 18 and a first clutch part 22 of a clutch 20 are located on the drive shaft 12 . The sun gear 38 meshes with at least one planet gear 30 which includes the planet carrier shaft 32 and which revolves in the ring gear 19 . The planet carrier shaft 32 is connected on the one hand to the output shaft 14 and on the other hand has the second clutch part 24 of the clutch 20 . The at least one planetary gear 30 meshes with a freewheel 26 to which a detent device 28 , for example provided as a jaw clutch, is assigned. The at least one planet gear 30 can be embodied as a single, double or stepped planet gear.

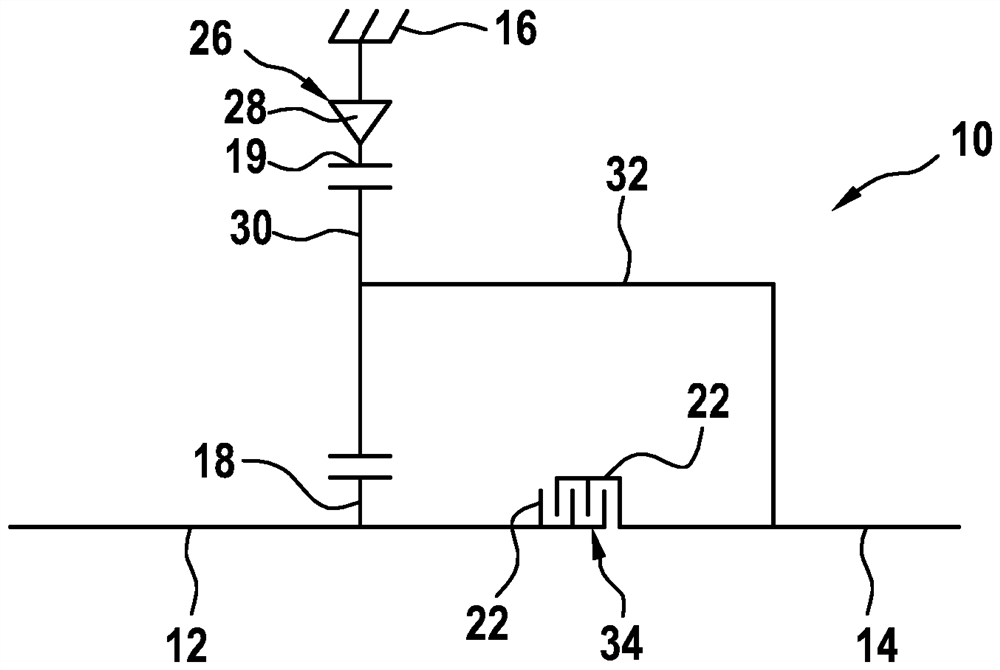

[0021] in accordance with Figure 2.1 and 2.2 A variant embodiment of the multi-speed planetary transmission 10 propos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com