Method for operating a wastewater-lifting system

A waste water and equipment technology, applied in the direction of mechanical equipment, chemical instruments and methods, water supply devices, etc., can solve problems such as functional capacity problems, lack of cut-off mechanism, etc., and achieve the effect of easy cleaning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

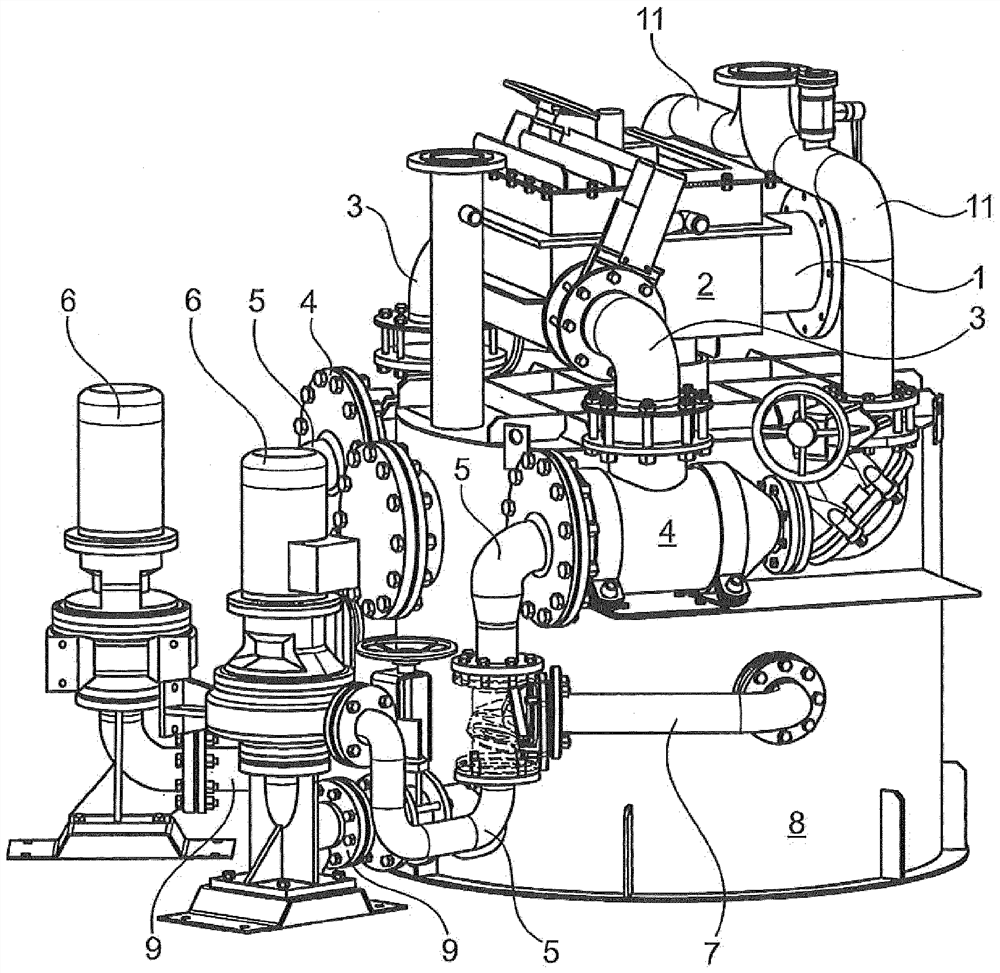

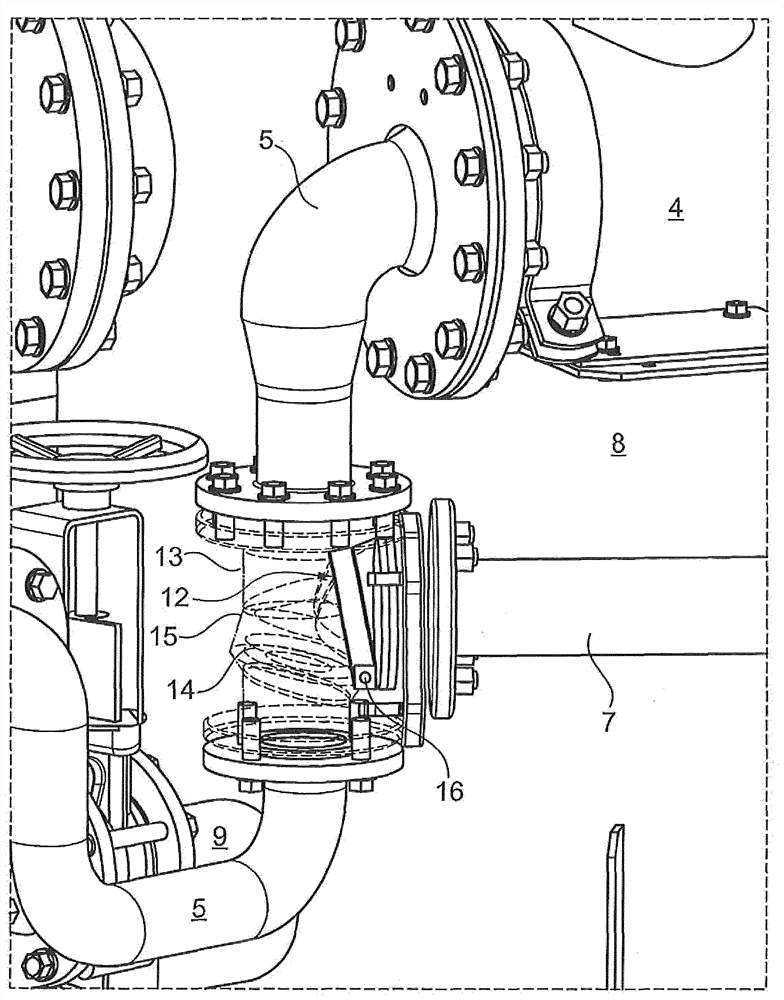

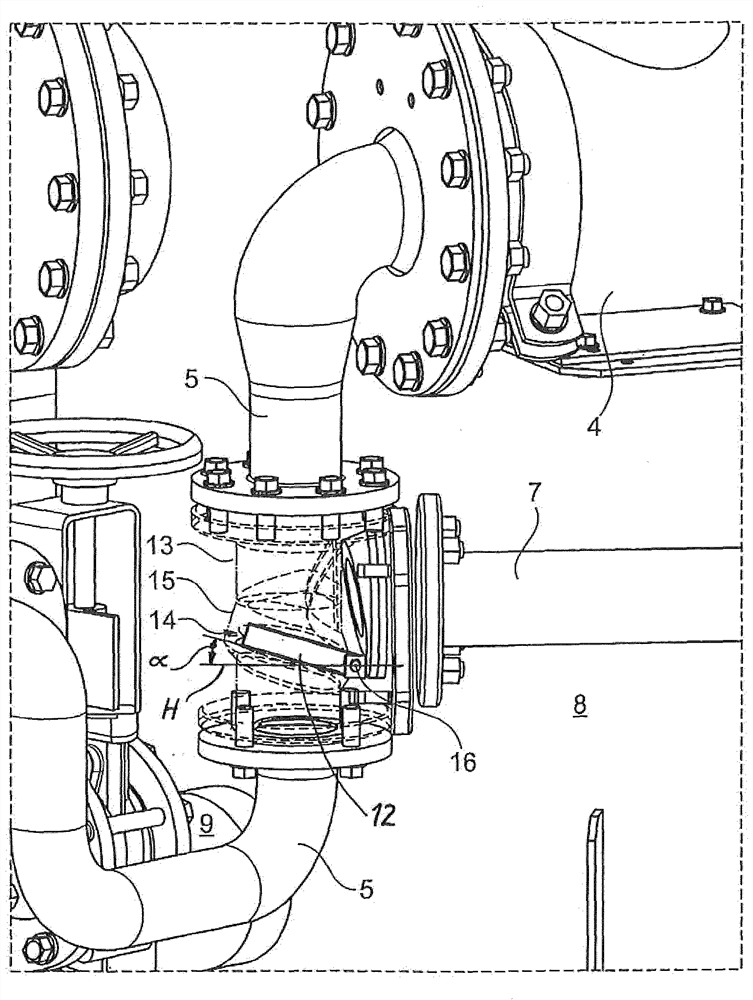

[0029] A waste water lifting device is shown in the drawing. The waste water lifting device firstly has an inflow 1 for waste water, which in the present exemplary embodiment diverts the waste water via an inflow distributor 2 and a feed line 3 into two clogging material collection containers 4 . Within the scope of the present exemplary embodiment, the waste water lifting device is designed as a symmetrical pair and has two clogging material collection containers 4 and additionally has two discharge lines or connecting lines 5 through which Alternatively, the lines are connected such that waste water pre-cleaned by means of the clogging material collection container 4 accordingly enters the associated pump 6 .

[0030] One clogging material collection container 4 or two clogging material collection containers 4 each serve to bring about the result that clogging material or solid material remaining in the associated clogging material collection container 4 is generally passed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com