A high-energy electron irradiation accelerator

A high-energy electron and accelerator technology, applied in the direction of DC voltage accelerators, electrical components, accelerators, etc., can solve the problems of inconvenient assembly and difficult to ensure the coaxiality of the accelerator, and achieve fast installation, reduce process difficulty, and facilitate installation and debugging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

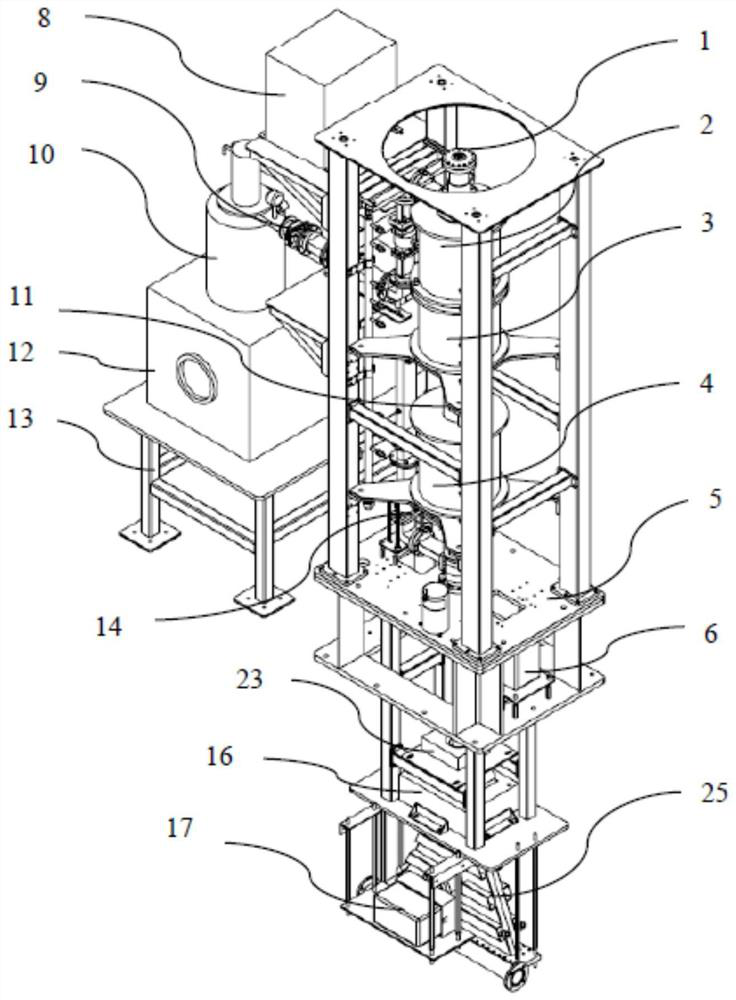

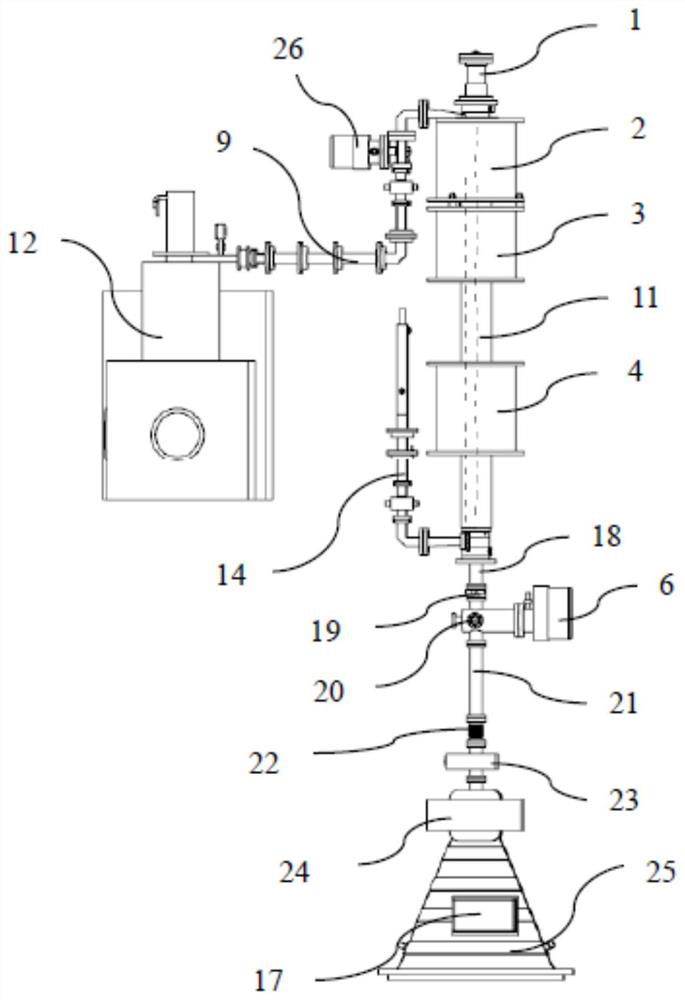

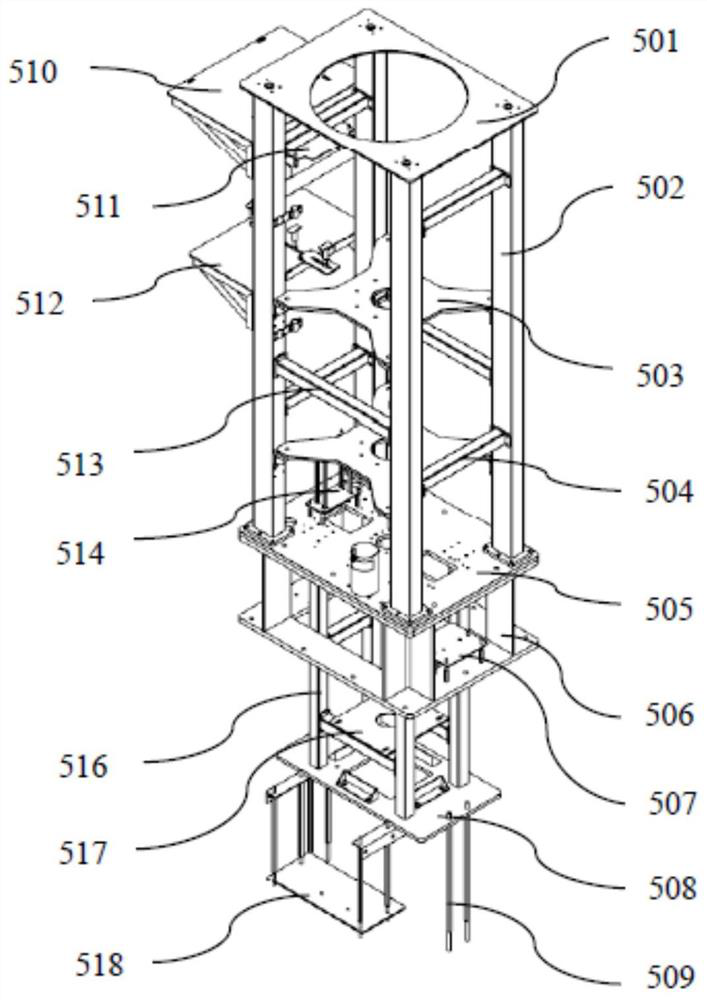

[0028] like figure 1 As shown, the present invention provides a high-energy electron irradiation accelerator, including an acceleration structure and a support structure; such as figure 2 As shown, the acceleration structure includes an electron gun 1, a focusing coil, an input waveguide system 9, a loading waveguide system 14, a beam detection system and a scanning system; the electron gun 1, the focusing coil, the beam detection system and the scanning system are connected in sequence and vertically Mounted on the accelerating structure for assembly; the input waveguide system 9 and the load waveguide system 14 are connected at the inlet and outlet of the focusing coil, respectively.

[0029] figure 2 Among them, the electron gun 1 is connected to the transformer 8 (installed on the transformer bracket 510 ), the accelerating tube 11 passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com