Conducting bar, junction box for high-voltage doubly-fed wind generator and installation method of junction box

A technology for wind turbines and junction boxes, which is used in the manufacture of motor generators, electromechanical devices, circuits, etc., can solve the problems of large space and bulkiness of the junction box, and achieve the effect of compact design and small space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

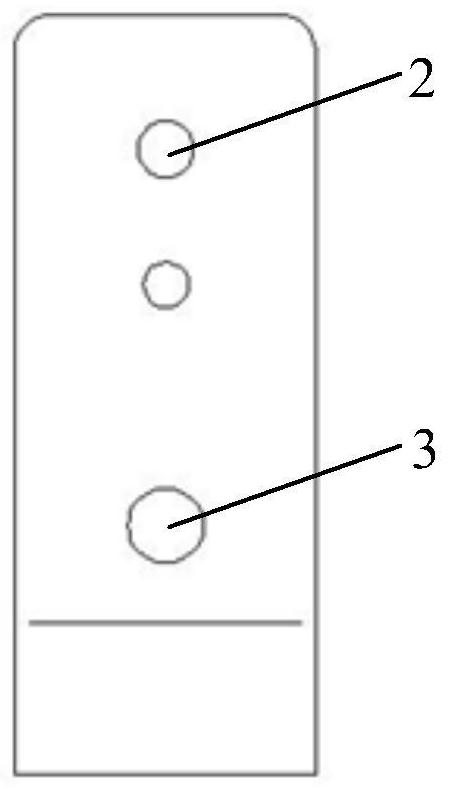

[0043] First, see figure 1 As shown, the present invention provides a conductive bar, which is applied in a junction box of a high-voltage doubly-fed wind turbine. The conductive bar 11 includes a conductive bar body, and the conductive bar body includes first, second and third mounting holes. And the connection lines at the positions of the three installation holes form a triangle; the first installation hole 2 is used to connect with the high-voltage insulator 5 in the junction box; the second installation hole 3 is used to connect with the stator lead wire 6 of the generator, and the stator leads The wire 6 is connected to the stator coil through the body of the junction box; the third installation hole 4 is used to connect with the user cable 7, and the user cable 7 is connected to the power grid through the body of the junction box.

[0044] Further, the connection lines of the positions of the three installation holes form an isosceles triangle, and the apex corners of t...

Embodiment 2

[0065] In the first aspect, this embodiment provides a conductive bar, the conductive bar 11 includes a conductive bar body, and the conductive bar body includes a first, a second and a third mounting hole, and the connection lines at the positions of the three mounting holes are formed. Triangle; the first installation hole 2 is used to connect with the high-voltage insulator 5 in the junction box; the second installation hole 3 is used to connect with the stator lead wire 6 of the generator, and the stator lead wire 6 is connected to the stator coil through the junction box body; The third installation hole 4 is used to connect with the user cable 7, and the user cable 7 is connected to the power grid through the junction box body.

[0066] see Figure 2-3 As shown in the figure, the connecting lines of the positions of the three mounting holes form a right-angled triangle, and the right angles are rounded; wherein, the first mounting hole 2 and the second mounting hole 3 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com