Liquid injection process of end face welding cylindrical lithium ion battery

A lithium-ion battery, cylindrical technology, applied in the direction of cylindrical shell battery/battery, secondary battery, battery pack parts, etc., can solve the problem of reducing the efficiency of liquid injection, the uniformity of liquid injection, and the difficulty of electrolyte penetration into the core, etc. Problems, to achieve the effect of improving the qualified rate, accelerating the infiltration and absorption, and improving the consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

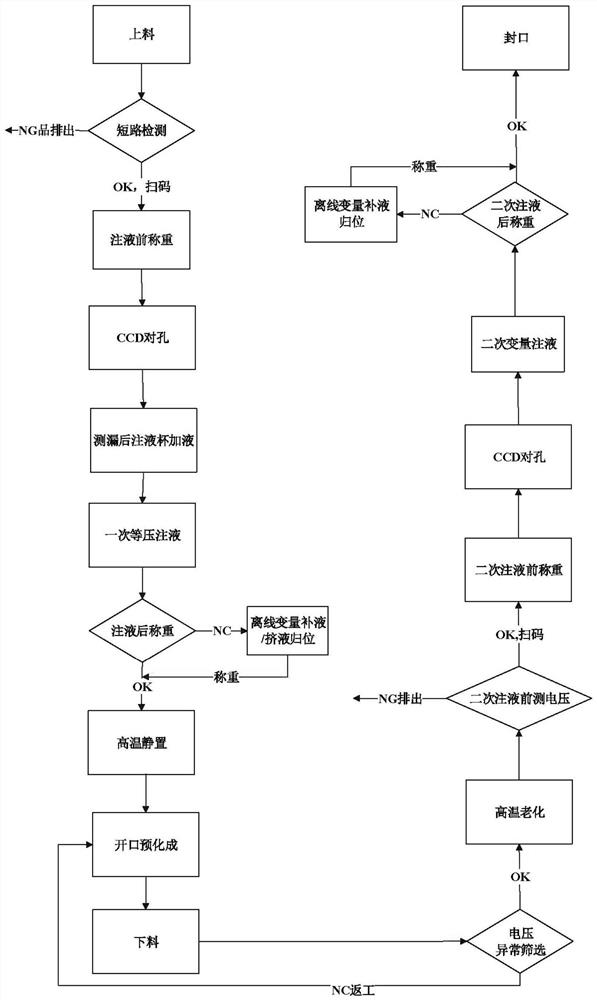

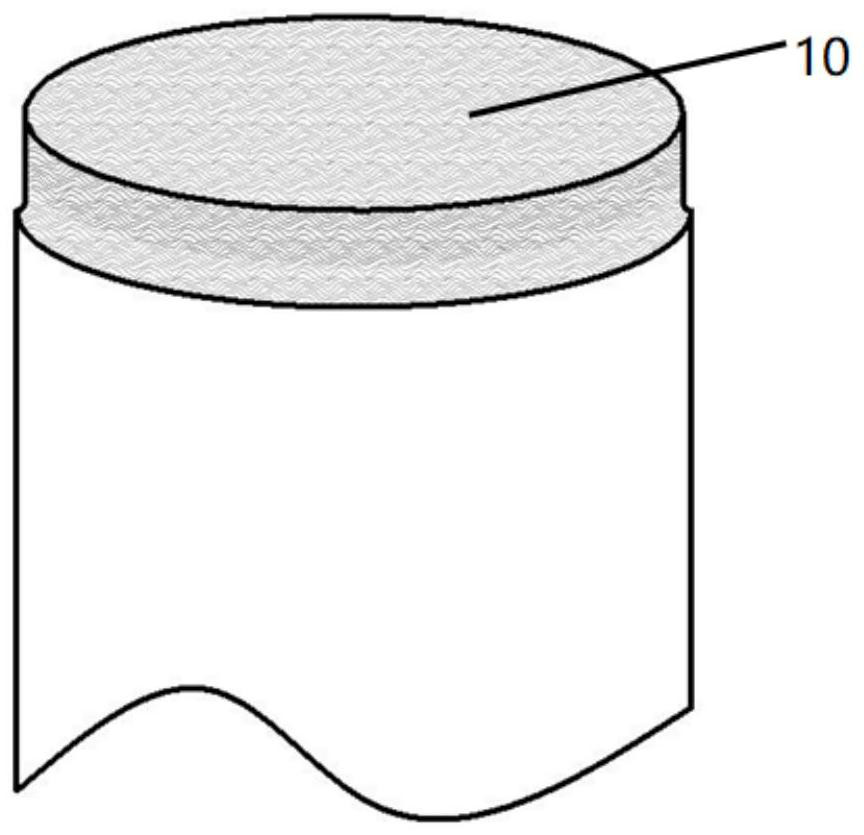

[0043] Embodiment: the end face welding cylindrical lithium ion battery (model is IFR32135-15Ah) adopted in this embodiment, the end face structure schematic diagram of the end face welding cylindrical lithium ion battery in this embodiment is as follows figure 2 As shown in , it has a dense end face 10, for the specific liquid injection process, please refer to figure 1 ,Proceed as follows:

[0044] 1) Loading: Transport the baked end-face welded cylindrical lithium-ion battery to the primary liquid injection loading area;

[0045] 2) Short-circuit test: Use a pulse short-circuit tester to conduct short-circuit detection on the battery in the feeding area. The test parameters are voltage 300V, time 0.2s, Vd1: 10%, Vd2: 20%. scrapping;

[0046] 3) One-time isobaric liquid injection: Scan the code and weigh the batteries that pass the short-circuit detection (record the weight in m1). After a certain amount of electrolyte is injected into the battery liquid injection cup, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com