Efficient heating gas chromatography device

A gas chromatographic device, high-efficiency technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of long waiting time for chromatographic column temperature increase, lower work efficiency, etc., to achieve improved heating efficiency, easy installation and hanging, uniform and efficient heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

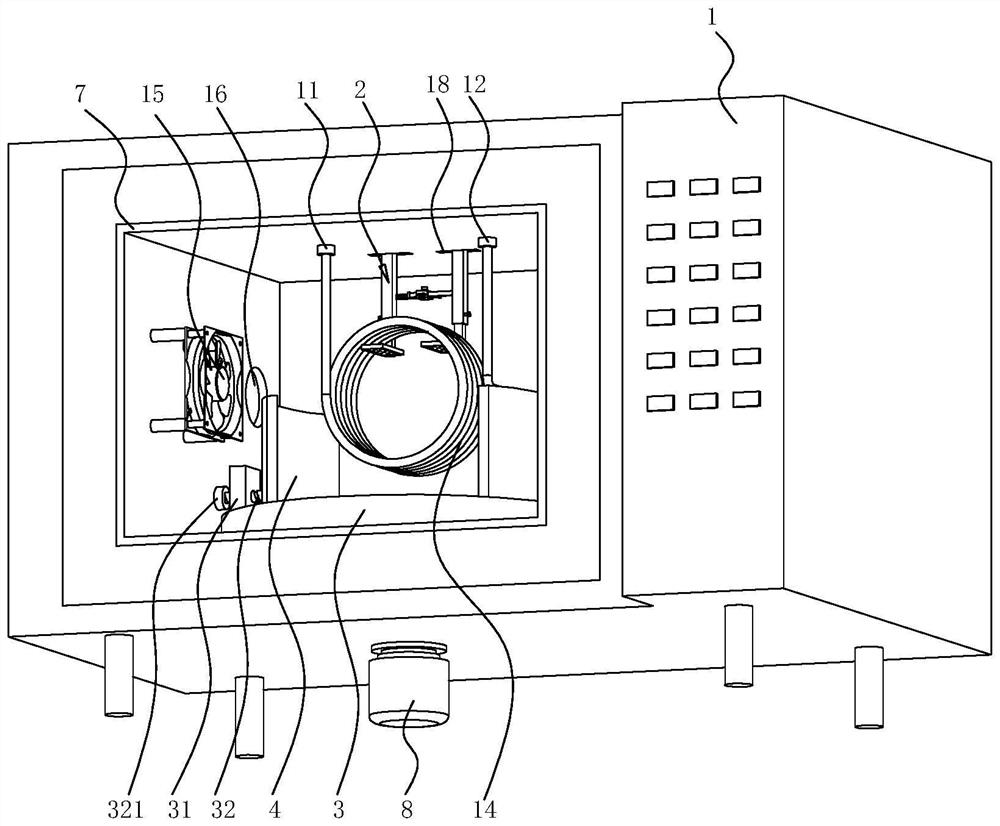

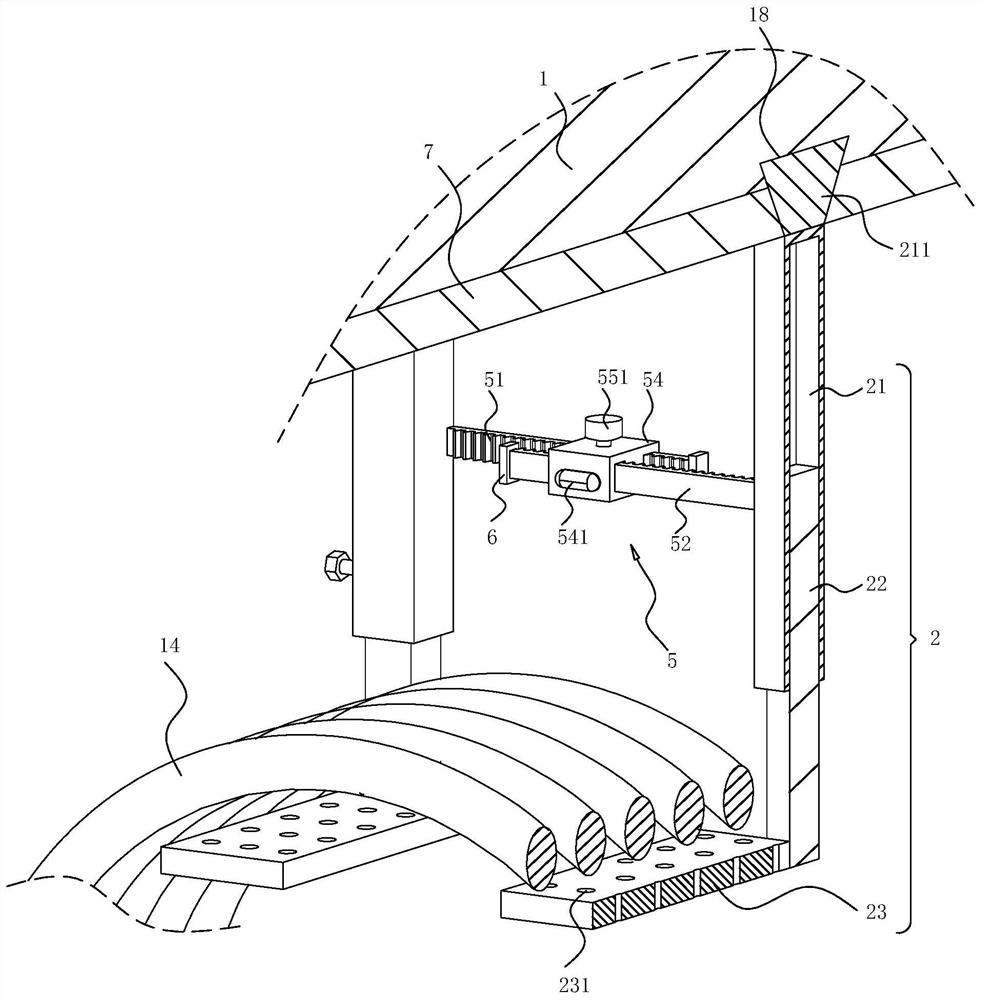

[0037] The following is attached Figure 1-4 The application is described in further detail.

[0038] The embodiment of the present application discloses a high-efficiency heating gas chromatography device.

[0039] refer to figure 1 and figure 2, a highly efficient heating gas chromatography device comprising a column box 1, the column box 1 is a rectangular column box 1, an opening door 13 is provided on the side wall of the column box 1, the opening door 13 is hingedly arranged with the column box 1, and the top of the column box 1 A sample inlet 11 and a sample outlet 12 are connected. A hanger 2 is slidingly arranged in the column box 1. There are two hangers 2. A chromatographic column 14 is arranged in the column box 1. The chromatographic column 14 is hung on the adjacent hanging rack. On the frame 2, a turntable 3 is arranged in the column box 1, and the turntable 3 is horizontally located at the bottom of the column box 1. The turntable 3 rotates on its own verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com