Dustproof mounting mechanism for wall-hanging stove

An installation mechanism and a technology for wall-hung boilers, applied in the field of wall-hung boilers, can solve the problems of troublesome wall-hung boilers disassembling and cleaning, increasing cleaning difficulties, affecting appearance and use, etc., achieving easy maintenance and adjustment, convenient maintenance and adjustment, and strong practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

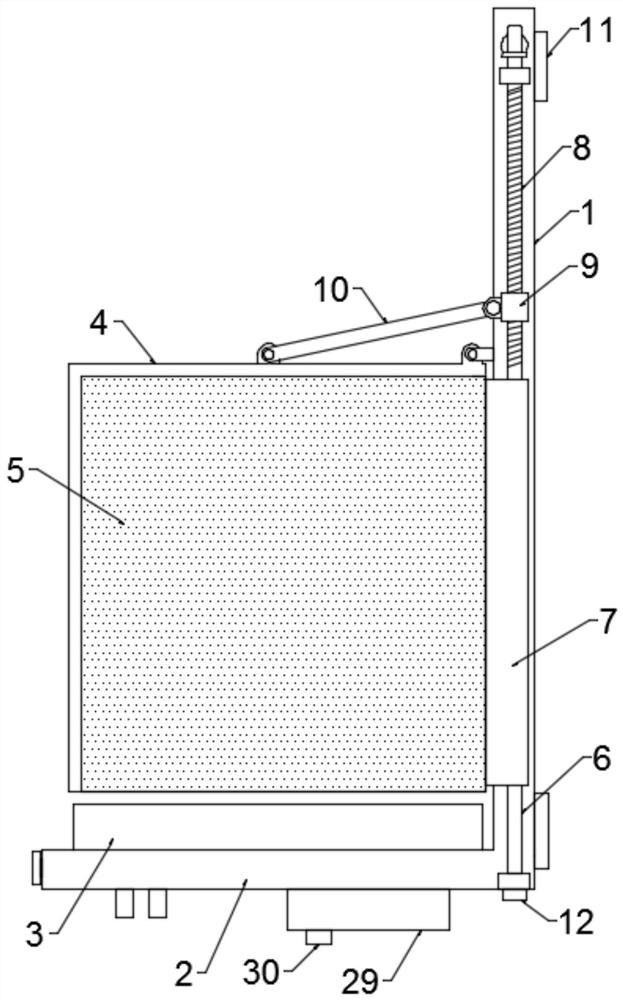

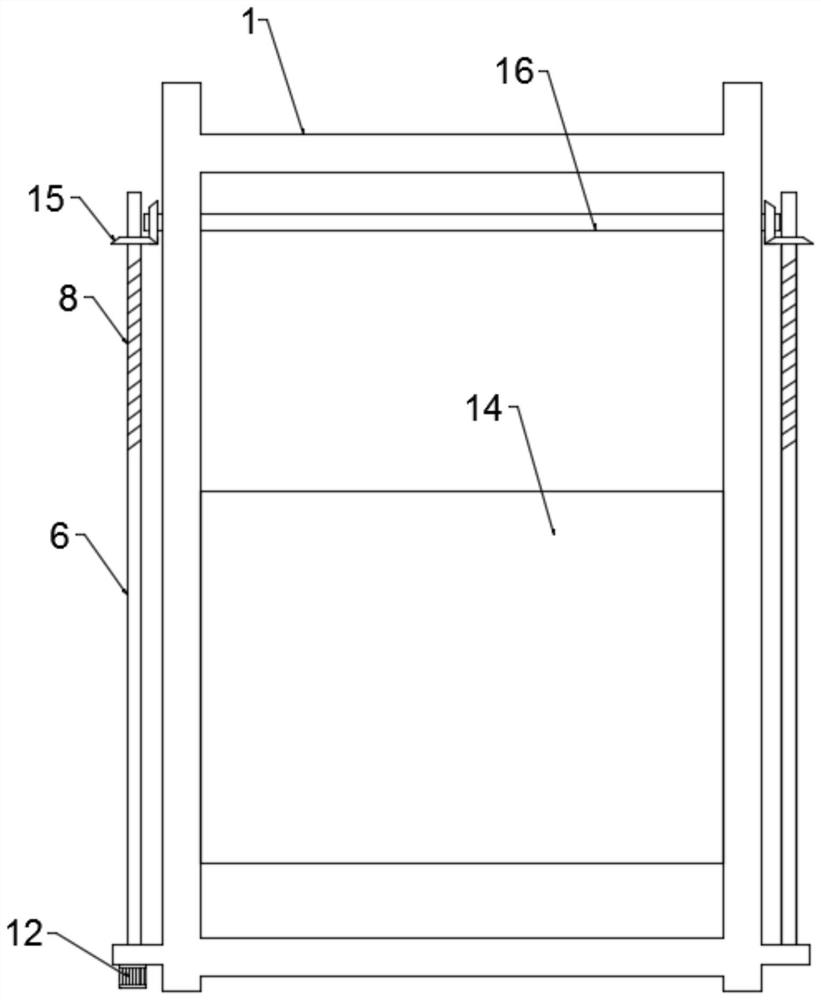

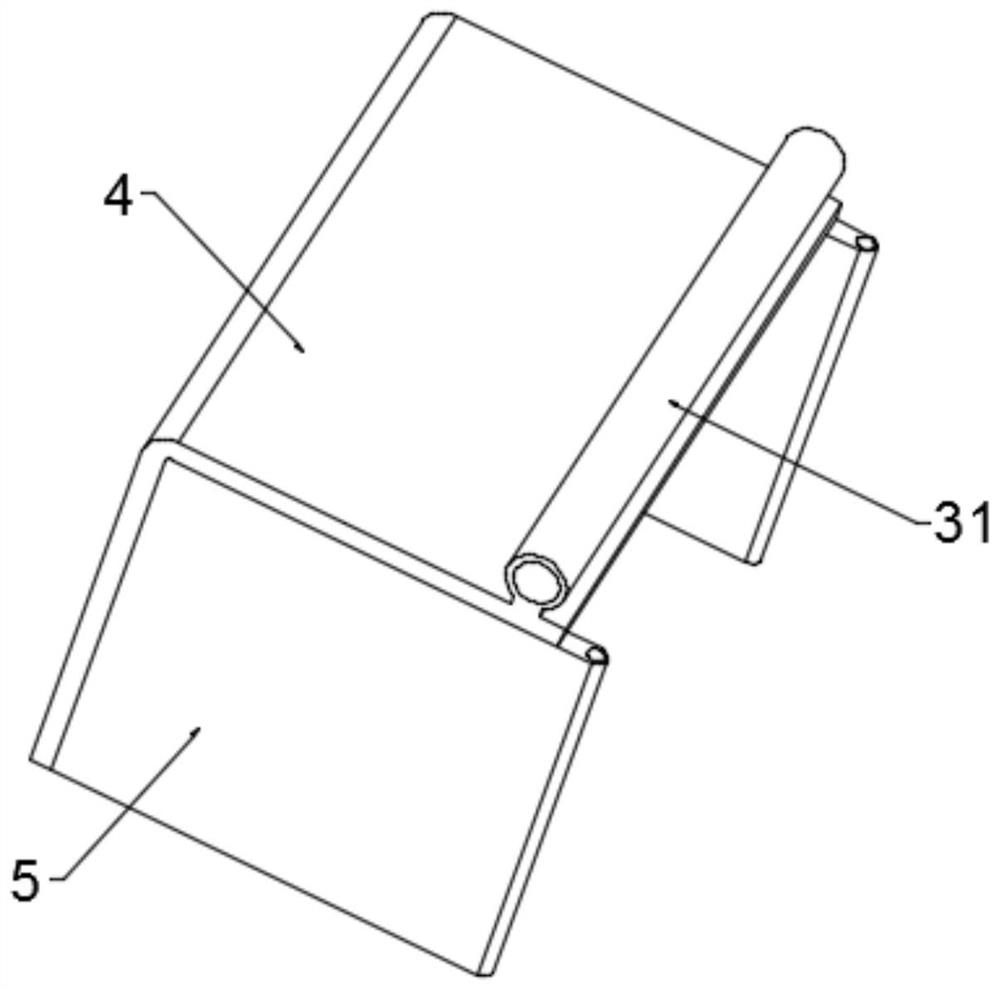

Embodiment 1

[0025] see Figure 1~6 , in an embodiment of the present invention, a dust-proof installation mechanism for a wall-hung boiler includes a fixed frame body 1 and a lower bracket 2, the sides of the lower bracket 2 are fixedly connected to the bottom end of the fixed frame body 1, and the fixed frame body 1 The upper and lower ends are fixed with a fixing plate 11 by welding, the lower bracket 2 is provided with a mounting seat 3 for installing a wall-hung boiler, and the fixing plate 11 is equipped with a fixing plate that cooperates with expansion bolts to fix the mechanism on the wall. Holes 13, the middle part of the fixed frame body 1 is provided with a transparent dustproof cover body, the transparent dustproof cover body includes a front top cover plate 4, a rear cover plate 14 and two side plates 5, the front top cover plate 4 The top side is provided with a rotating pin shaft sleeve 31 and the rotating pin shaft sleeve 31 is hinged with the side wall of the fixed frame ...

Embodiment 2

[0030] see figure 1 and 6 The difference between the embodiment of the present invention and the embodiment 1 is that the lower end of the second threading part 28 is provided with a sealing cover 29 and the bottom of the sealing cover 29 is provided with a jacket 30 for water pipes to pass through to avoid water leakage of the wall-hung boiler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com