Elevator guide device and control method thereof

An elevator guide device and elevator technology, applied in the direction of transportation, packaging, elevators, etc., can solve the problems of difficult installation of hollow elevator guide rails, failure to ensure passenger safety, troublesome maintenance, etc., and achieve convenient and quick installation and post-maintenance adjustment, and facilitate post-maintenance The effect of adjustment and car running is stable and safe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

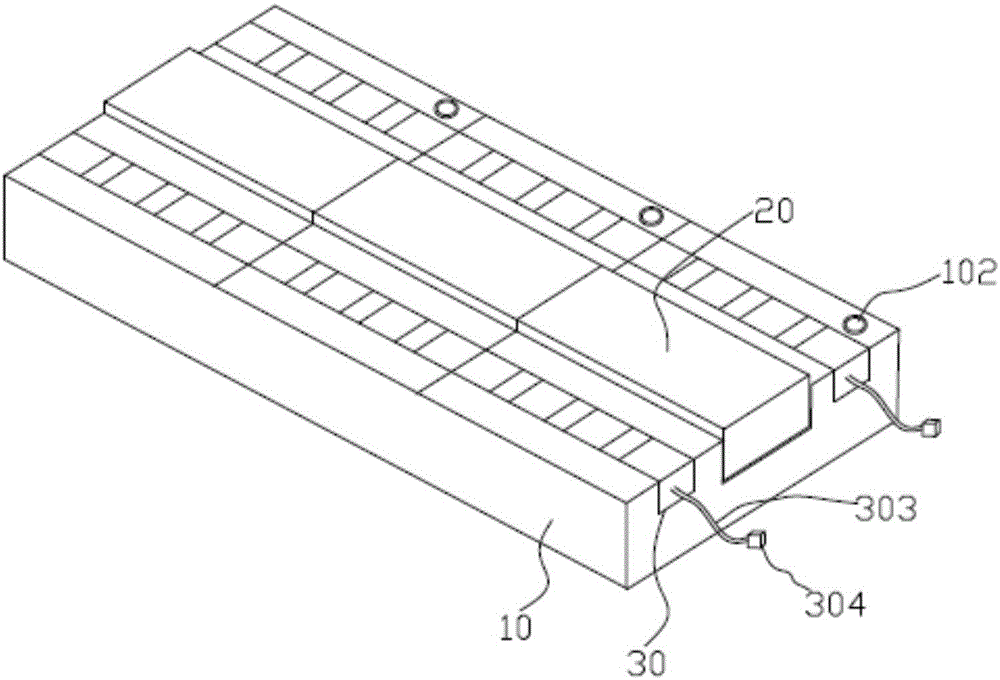

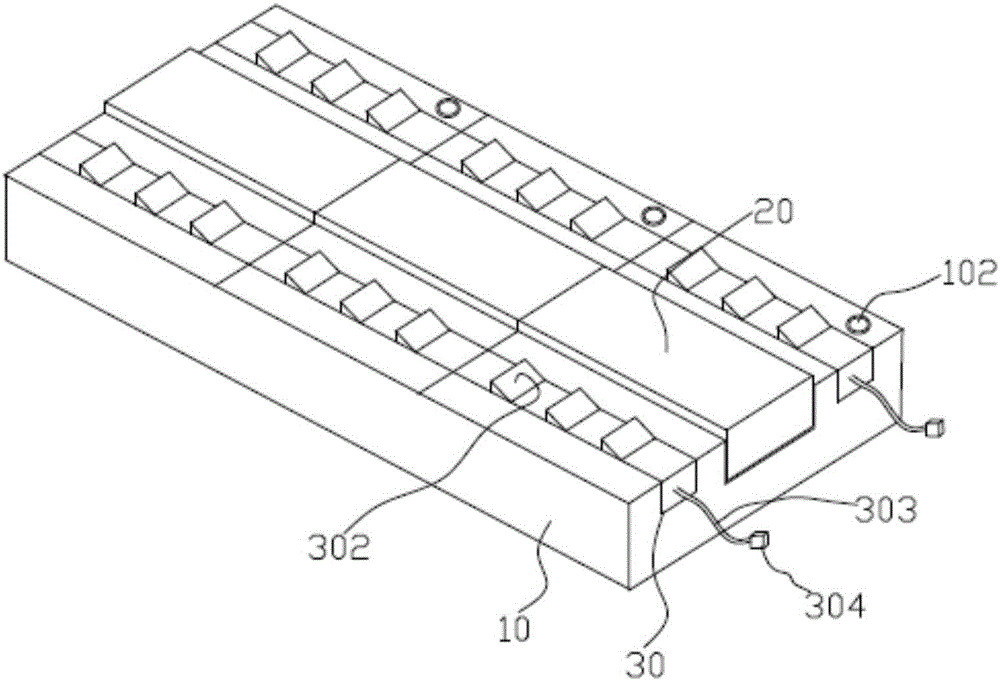

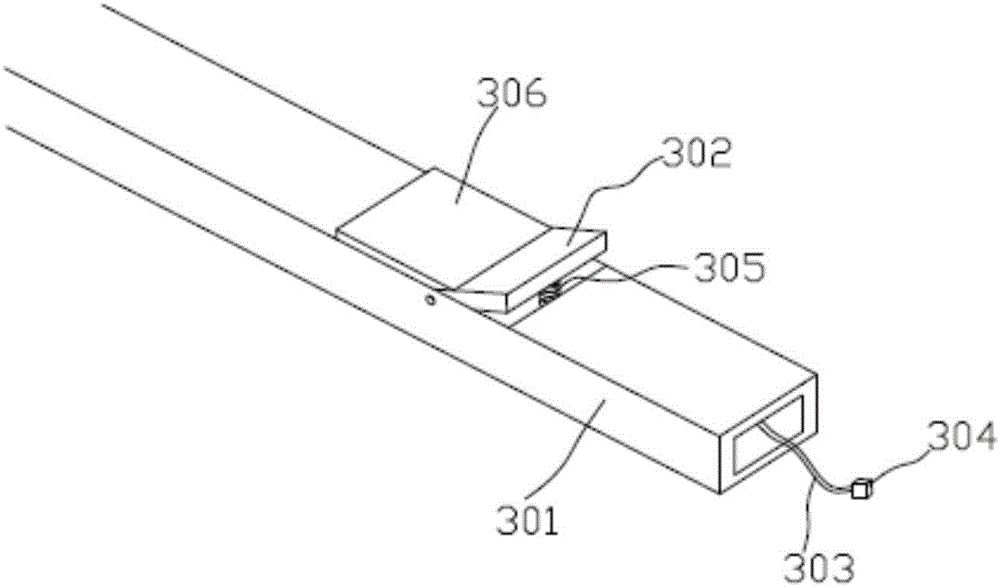

[0033] refer to Figure 1-5 , a guide device for an elevator, comprising a guide rail 10 and a guide bar 20, the guide rail 10 is provided with a concave groove 101 along the length direction of the guide rail, the guide bar 20 is adapted to the concave groove 101, and the guide bar 20 is slidably set In the concave groove 101, the height of the guide bar 20 is greater than the depth of the concave groove 101, and the difference between the two is 8mm, and can also be 9mm or 10mm.

[0034] During installation, guide rails 10 are installed on the inner walls of the opposite sides of the elevator shaft to form the running track of the car. The length of the guide rail 10 is equal to the height of the floor, and it is installed layer by layer. The combined running track of the floors makes installation and later maintenance easier. The adjustment is more convenient and fast; guide strips 20 are installed on the opposite sides of the elevator car, and the guide strips 20 are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com