Slip assembly capable of being rapidly milled for downhole tool

A technology of downhole tools and components, which is applied in wellbore/well parts, sealing/packing, earthwork drilling, etc. It can solve the problems that integral slips and segmented slips are not easy to grind and mill, and achieve easy mass production Assembling, anti-collision, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

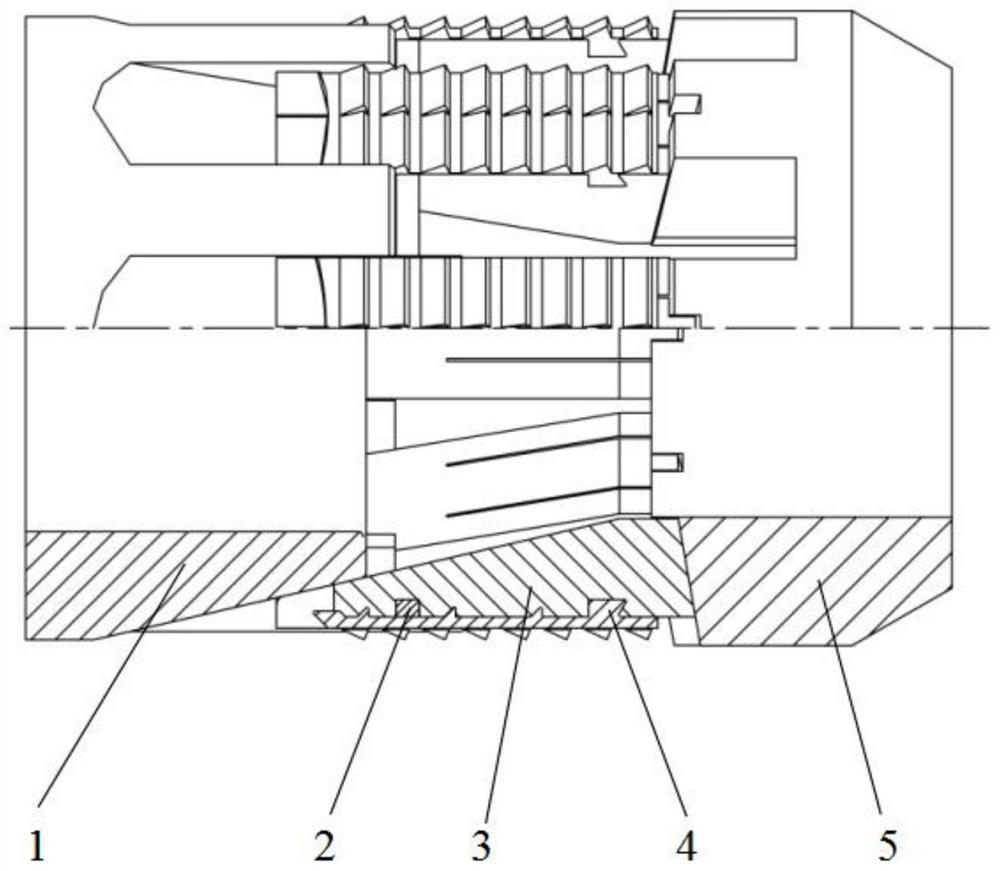

[0020] Specific embodiments: the present invention will be described in further detail below in conjunction with the accompanying drawings, a

[0021] The rapid millable slip assembly for the lower tool includes:

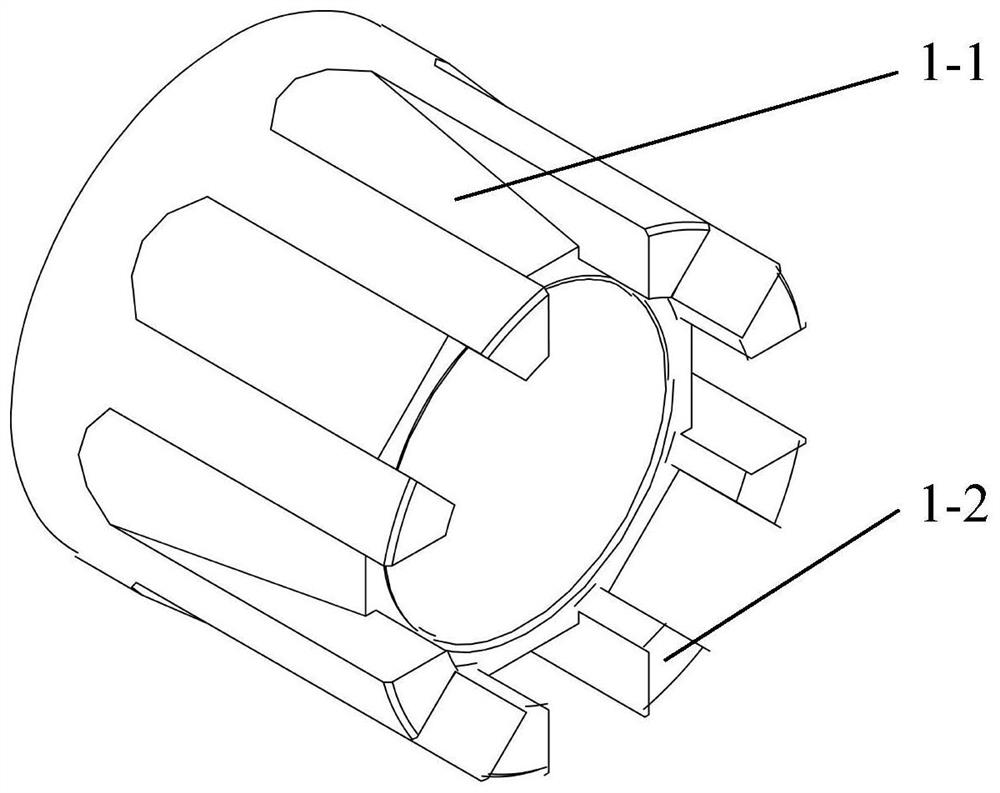

[0022] Cone 1, the cone 1 is used to expand and support the slip base 3 during setting, and at the same time limit the circumferential displacement of the slip base 3; the main body assembly, the main body assembly is plugged and installed between the cone 1 and the italic 5 and the italic body 5, the italic body 5 is used to support the tail of the slip base body 3;

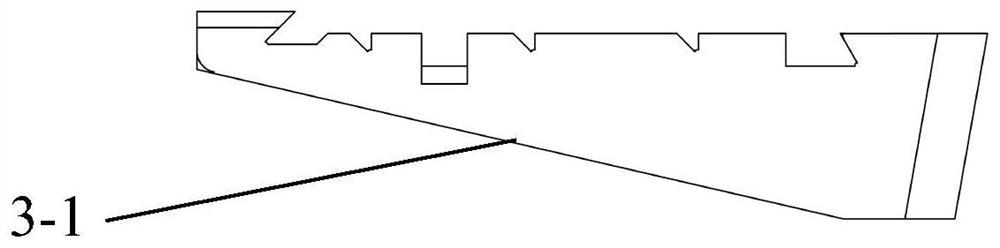

[0023] The main body assembly includes a fixed ring 2 , a slip base 3 , and a slip piece 4 ; the fixed ring 2 hoops the slip base 3 into a circle, and the slip piece 4 is inserted on the upper surface of the slip base 3 .

[0024] The cone 1 is inserted into the slip base 3; the fixing ring 2 hoops the eight slip bases 3 into a circle, and the outer surface of the slip base 3 is inserted with a slip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com