Glass composition, method for producing glass composition, conductive paste, and solar cell

A technology of glass composition and solar cell, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, photovoltaic power generation, etc., can solve the problems of increased manufacturing process and increased cost, and achieve excellent reliability and productivity, and burn-through high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

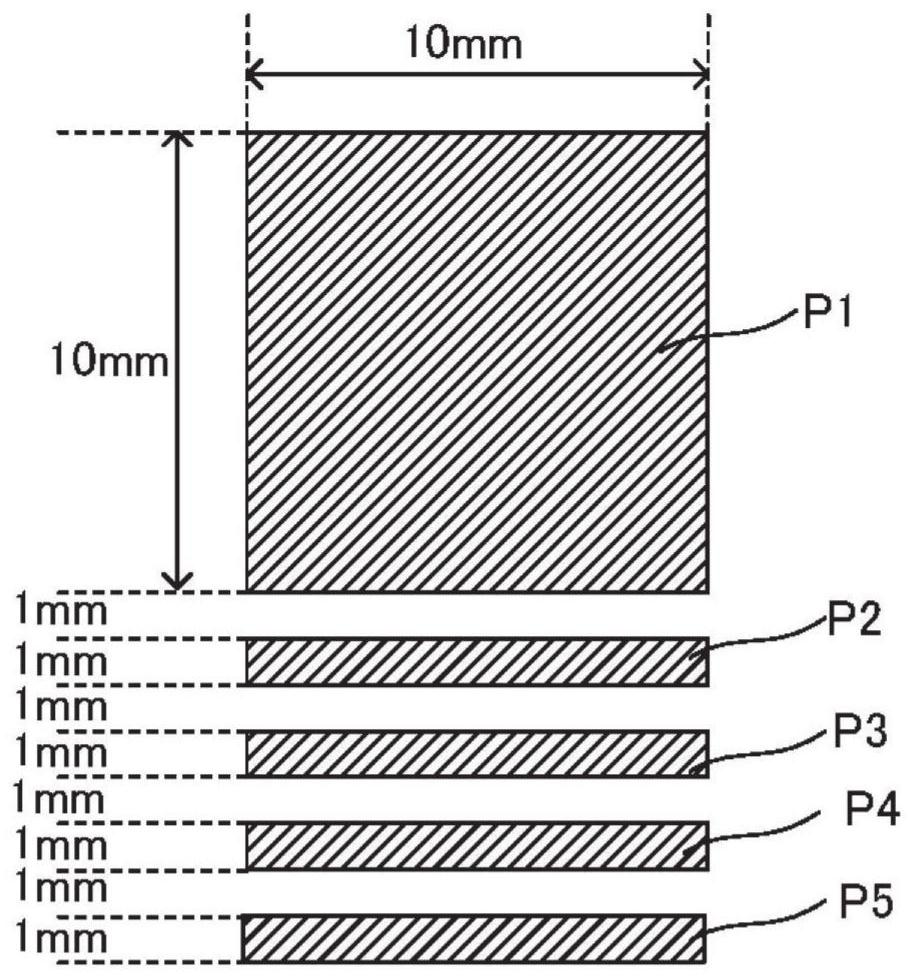

Image

Examples

example 1~13、 example 21~24

[0161] As the first glass composition used in the manufacture of the glass compositions of Examples and Comparative Examples, the glass composition used in Comparative Examples, and the second glass composition, the compositions and characteristics shown in Tables 1 to 3 were produced. glass powder. That is, mix and mix raw material powders so as to have the compositions shown in Tables 1 to 3, melt in an electric furnace at 1000°C to 1300°C using a platinum crucible for 30 minutes to 1 hour, and shape it into a thin plate glass, and then use a ball mill to 50 The sheet-shaped glass was dry-pulverized so as to be in a predetermined range (0.5 μm to 10 μm), and coarse particles were removed with a 150-mesh sieve.

[0162] For the glass compositions (glass powders) of Examples 1 to 13, glass powders obtained in the following manner were used: In order to further reduce D within the range specified above 50 , after the above-mentioned dry pulverization, air classification is car...

example 31~46、 example 51~53

[0177] Using the first glass powder (G1-G9) obtained above, the glass powder (G10-G13) used in the comparative example, the second glass powder (G21-G23) and the glass powder (G24) used in the comparative example were produced. Glass compositions (glass powders) of Examples 31 to 46 and Examples 51 to 53 having the compositions shown in Tables 4 to 6. For the glass powders of Examples 31 to 46, by using the first glass powder shown in Table 4 and Table 5 or the glass powder used in the comparative example and the second glass powder or the glass powder used in the comparative example at a mass ratio of 1:1 Made by mixing. The glass powders of Examples 51-53 were manufactured by mixing the 1st glass G7 and the 2nd glass G21 in the ratio shown in Table 6. In each example, mixing was performed for 1 hour using a V-type mixer.

[0178] (evaluate)

[0179] Using the glass powders of Examples 31 to 46 and Examples 51 to 53, an electrically conductive paste for forming an Al elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap