Energy-saving and environment-friendly sludge dewatering machine

A sludge dewatering machine, an energy-saving and environment-friendly technology, applied in the direction of water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problem that sludge water is difficult to seep out, and increase the degree of flow , to avoid the effect of dirt accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

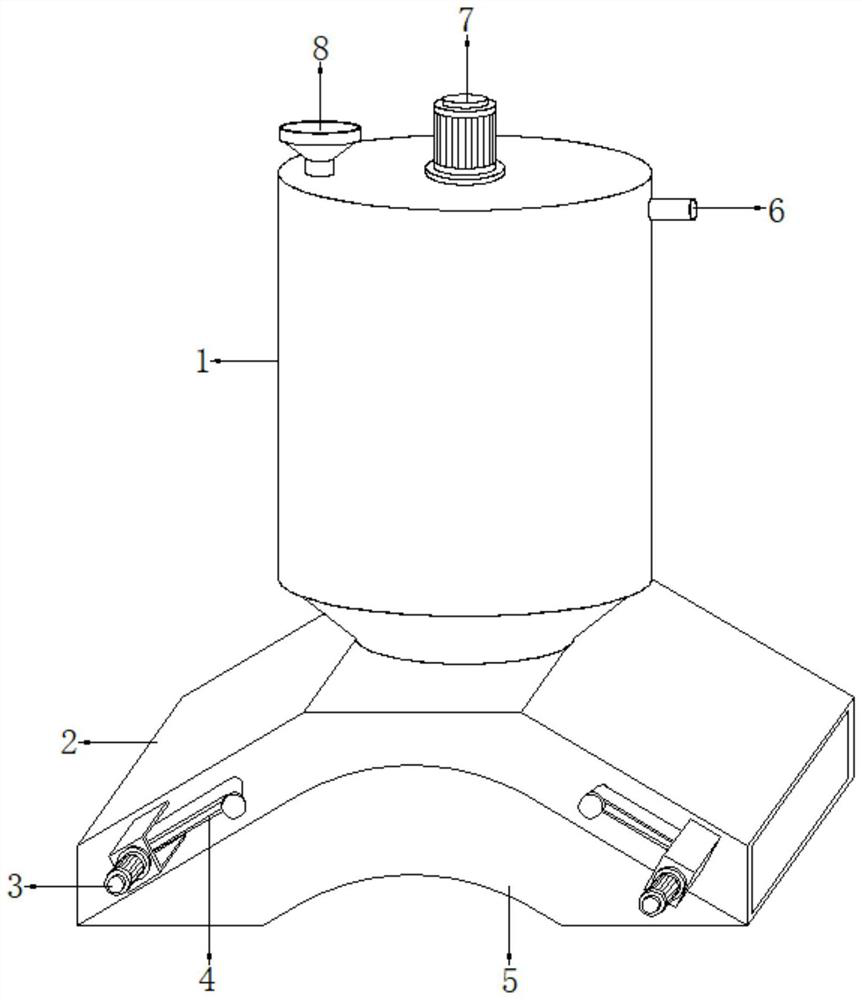

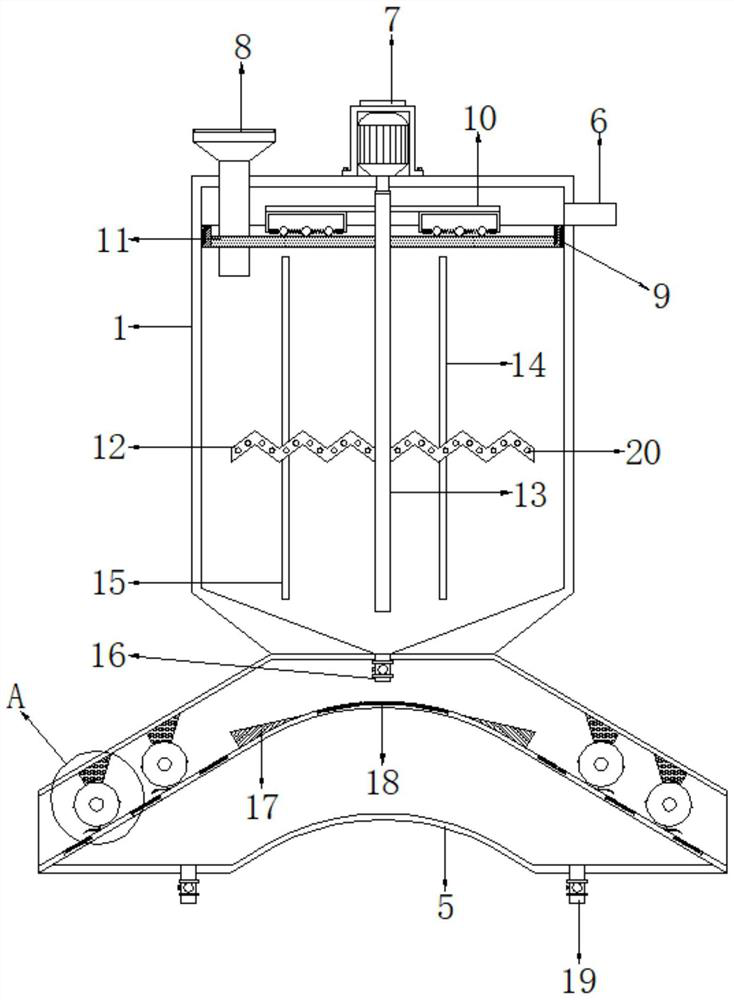

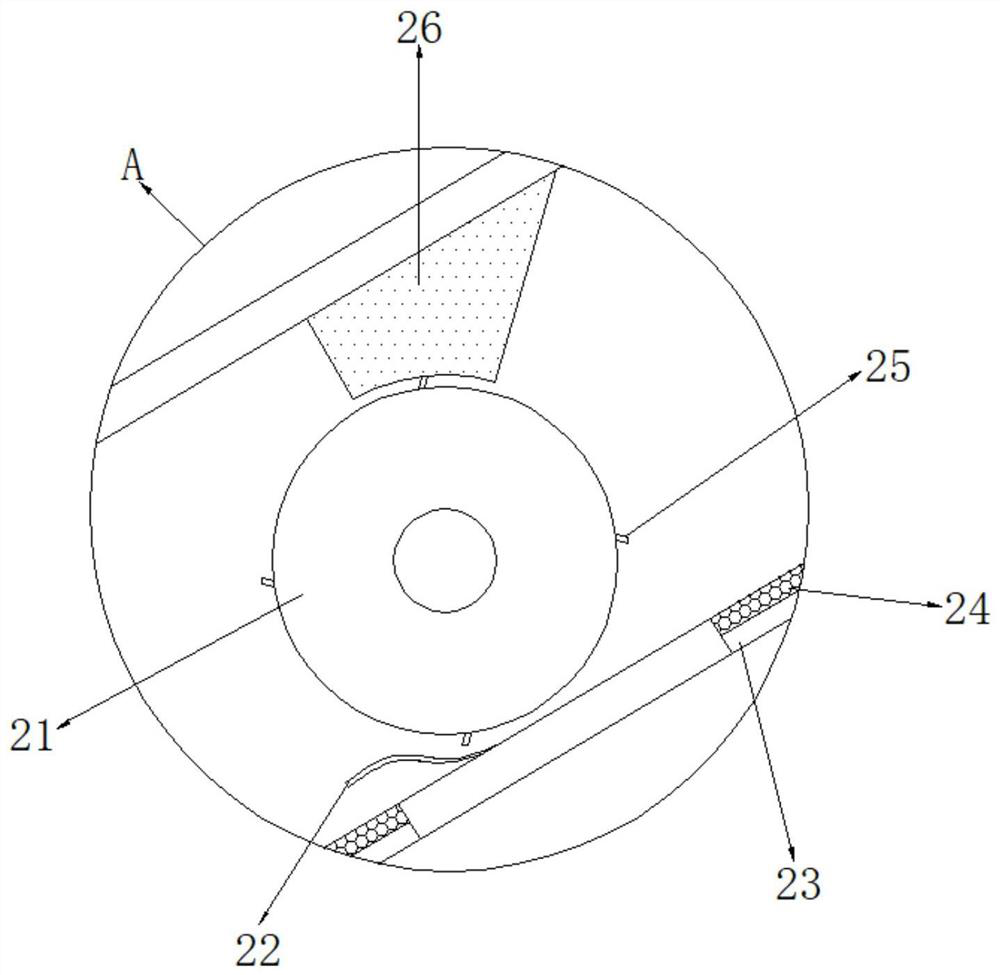

[0031] refer to Figure 1-4 , an energy-saving and environment-friendly sludge dewatering machine, comprising a treatment barrel 1, the inner wall of the treatment barrel 1 near the top is welded with a surrounding frame 9, and the inner wall of the surrounding frame 9 is connected with a sponge layer 11 by bolts, and the top side of the treatment barrel 1 The feed hopper 8 passing through the sponge layer 11 is connected by bolts, and the top of one side of the processing barrel 1 is welded with a flood pipe 6, and the middle position of the top of the processing barrel 1 is connected with a first motor 7 by bolts, and the first motor 7 The bottom of the output shaft extending into the processing barrel 1 is connected with a rotating shaft 13 by bolts, and the rotating shaft 13 passes through the inside of the sponge layer 11, and both sides of the outer wall of the rotating shaft 13 are welded with agitating blades 12, and the agitating blades 12 are bent. One side of the st...

Embodiment 2

[0041] refer to Figure 5 , an energy-saving and environment-friendly sludge dewatering machine. Compared with Embodiment 1, the bottom of the rotating shaft 13 is welded with a fixed shaft, and the outer wall of the fixed shaft is welded with a spiral blade 30, and the diameter of the spiral blade 30 is from top to bottom. slowing shrieking.

[0042] Working principle: Since the diameter of the spiral blade 30 gradually decreases from top to bottom, and the bottom of the processing barrel 1 is set in a funnel shape, when the sludge is introduced into the processing frame 2 through the discharge pipe 16, it can be driven and fixed by the rotating shaft 13 The shaft and the helical blade 30 rotate, and the helical blade 30 is used to drive the sludge to fall to increase the falling speed of the sludge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com