Packaging device for clothing production line and using method thereof

A production line and clothing technology, which is applied in the field of clothing production, can solve problems such as unsatisfactory tightening effect, high labor intensity, and the accumulation of goods affecting fire exits, etc., to achieve the effect of ensuring the tightening effect and work efficiency, and improving the packing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

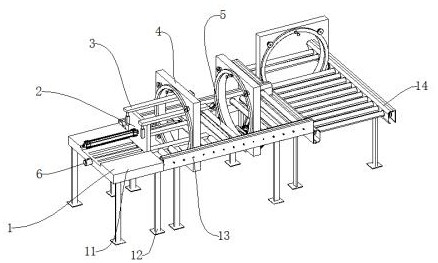

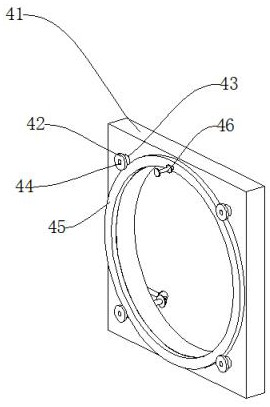

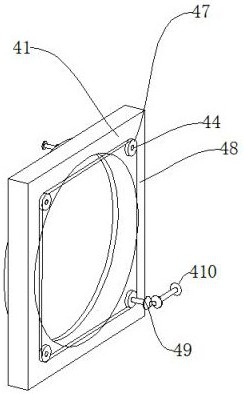

[0052] Such as Figure 1-Figure 7 As shown, a packaging device for a clothing production line includes a clamping mechanism 3 for clamping clothing, a pushing mechanism 2 for pushing materials, and a packaging mechanism 4 for packaging. One end of the pushing mechanism 2 is installed with The clamping mechanism 3, the other end of the pushing mechanism 2 is connected to the support mechanism 1, a transmission mechanism 5 is arranged inside the support mechanism 1, a packing mechanism 4 is arranged between the transmission mechanisms 5, and a discharge mechanism 6 is connected to the power end of the pushing mechanism 2;

[0053] The support mechanism 1 includes a placing workbench 11, a column 12, a first stand 13, and a second stand 14. The first stand 13 is arranged on the discharge side of the workbench 11, and the discharge side of the first stand 13 is arranged There is a second stand 14, and the lower ends of the workbench 11, the first stand 13, and the second stand 14 ...

Embodiment 2

[0060] The difference between this embodiment and embodiment 1 is:

[0061] Such as Figure 8 , the discharging mechanism 6 includes a limit groove 61, a power groove 62, a second moving slider 611, and a retracting piston rod 612. Move the slider 611, one end of the second moving slider 611 is connected to the retracting piston rod 612, the retracting piston rod 612 is installed on the retracting cylinder 613, and the retracting cylinder 613 is connected by bolts to place the workbench 11, when the traversing seat 21 needs to drive the clothing to move At this time, the retracting cylinder 613 can be used to drive the retracting piston rod 612 to cooperate with the second moving slider 611, thereby driving the traversing seat 21 to move.

[0062] A method for using a packaging device for a clothing production line, comprising the following steps:

[0063] a. First move the traversing seat 21 to the upper end of the workbench 11, start the lifting cylinder 36 to raise the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com