Fastener pulling and twisting device

A fastener and fastening technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of slow speed, high cost of fastener wrench device, and slow rotation speed of hydraulic wrench

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

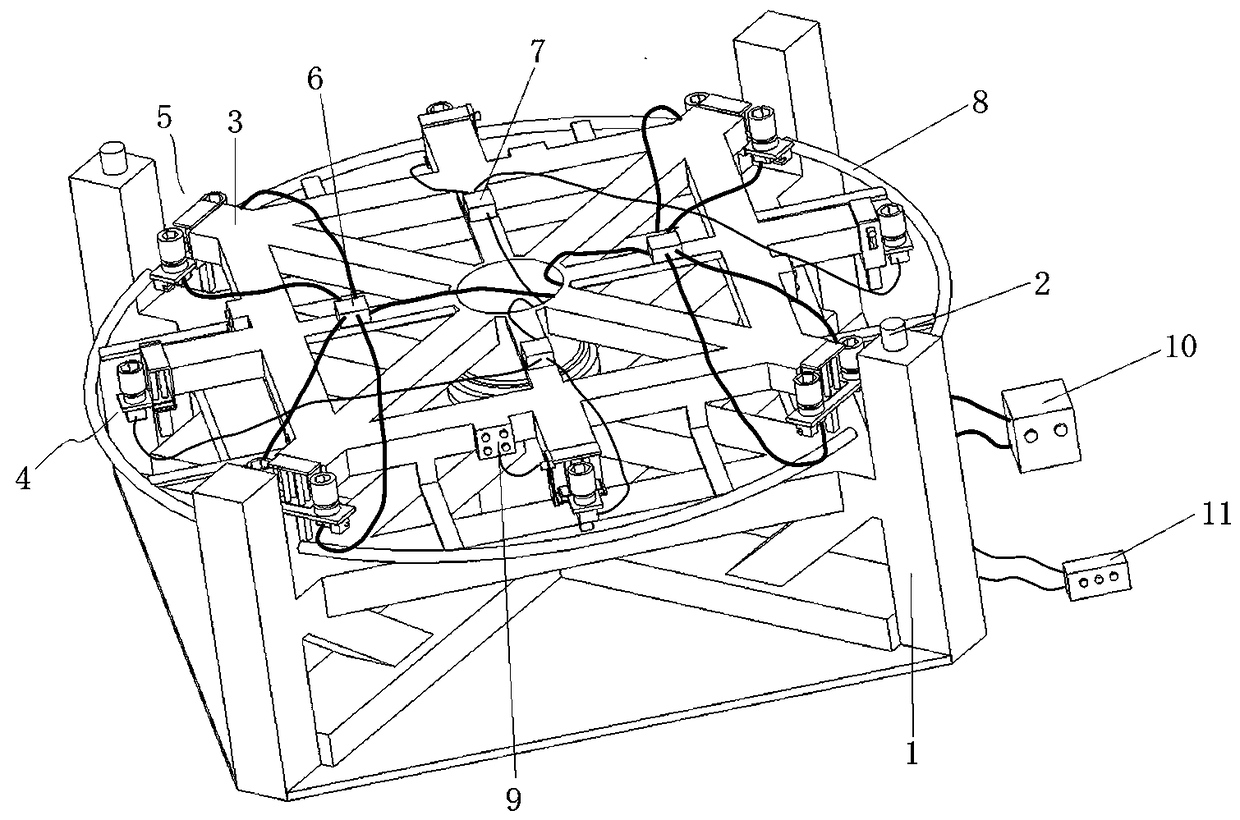

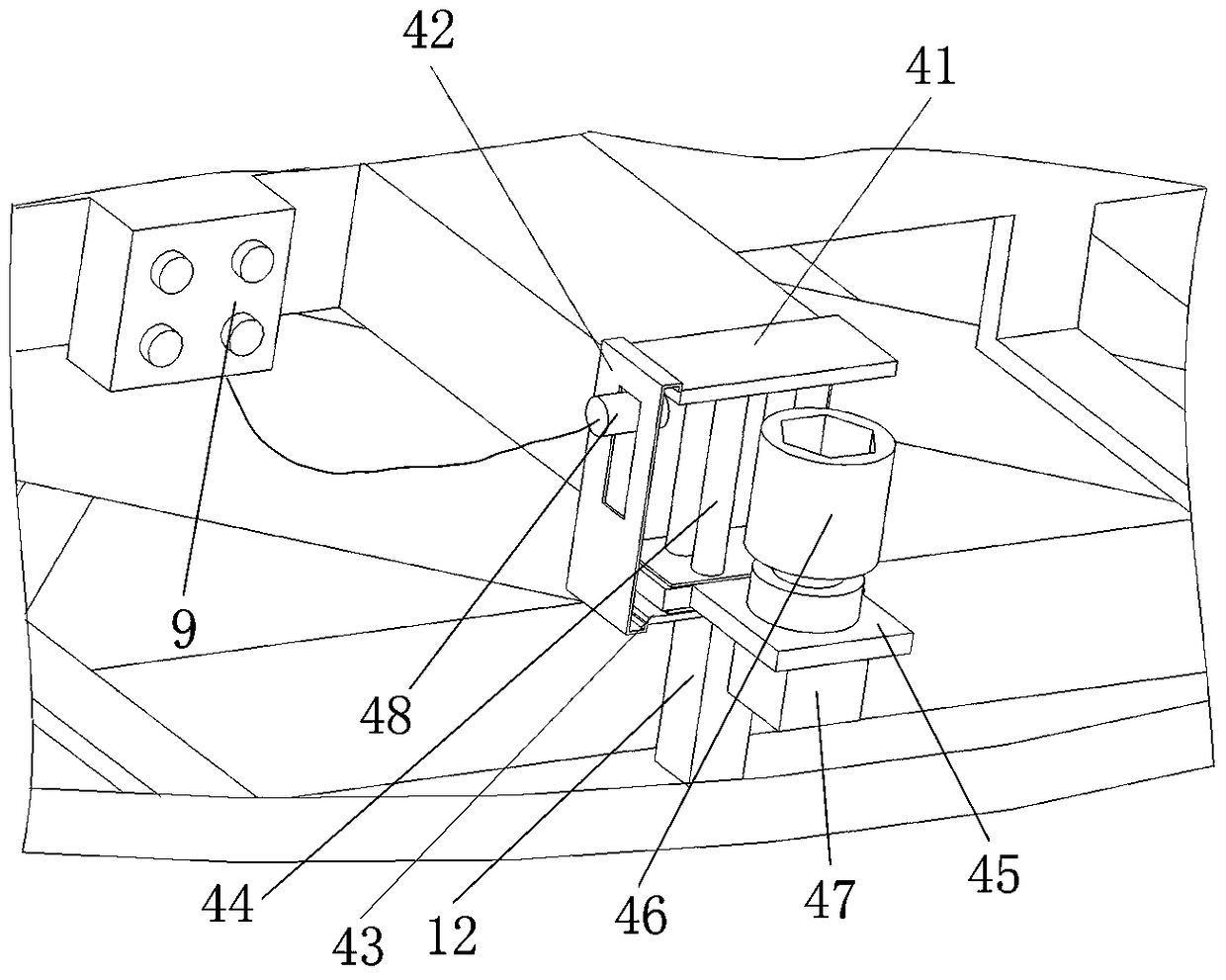

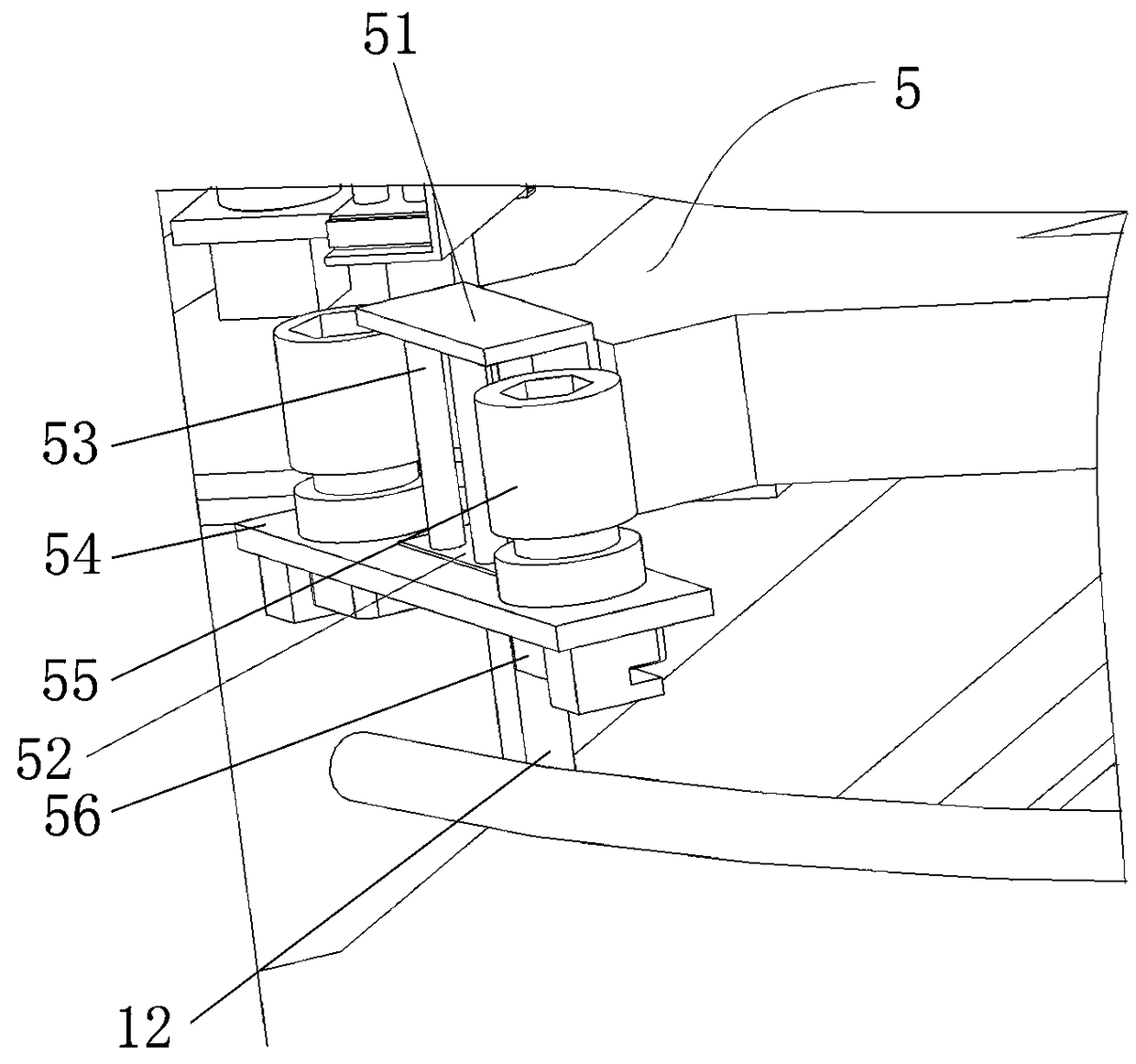

[0023] Specific embodiments of the fastener wrench device of the present invention, such as Figure 1 to Figure 4 As shown, the fastener wrench device is a wrench device for tightening bolts evenly spaced along the circumferential direction, and is mainly composed of a fixed seat 1, a movable seat and a wrench assembly. The wrench assembly includes a pre-tightening wrench assembly 4 for pre-tightening the bolts and a tightening wrench assembly 5 for final tightening the bolts.

[0024] The movable seat is rotatably assembled on the fixed seat through bearings, and the rotation axis extends along the up-down direction. The movable seat includes a plurality of crossbeams 3 arranged crosswise in the shape of a rice ball. The central intersection of each crossbeam 3 is rotatably assembled on the fixed seat through the above-mentioned bearings. Each crossbea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com