Degree-of-freedom printing base table of SLM equipment

A technology of degrees of freedom and abutment, which is applied in the direction of improving process efficiency, additive processing, and energy efficiency, etc., can solve the problem of unqualified processed products, difficulty in meeting the requirements of axisymmetrical rotating parts, and lack of freedom to print abutments Drive device and other problems, to achieve the effect of quality assurance, convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

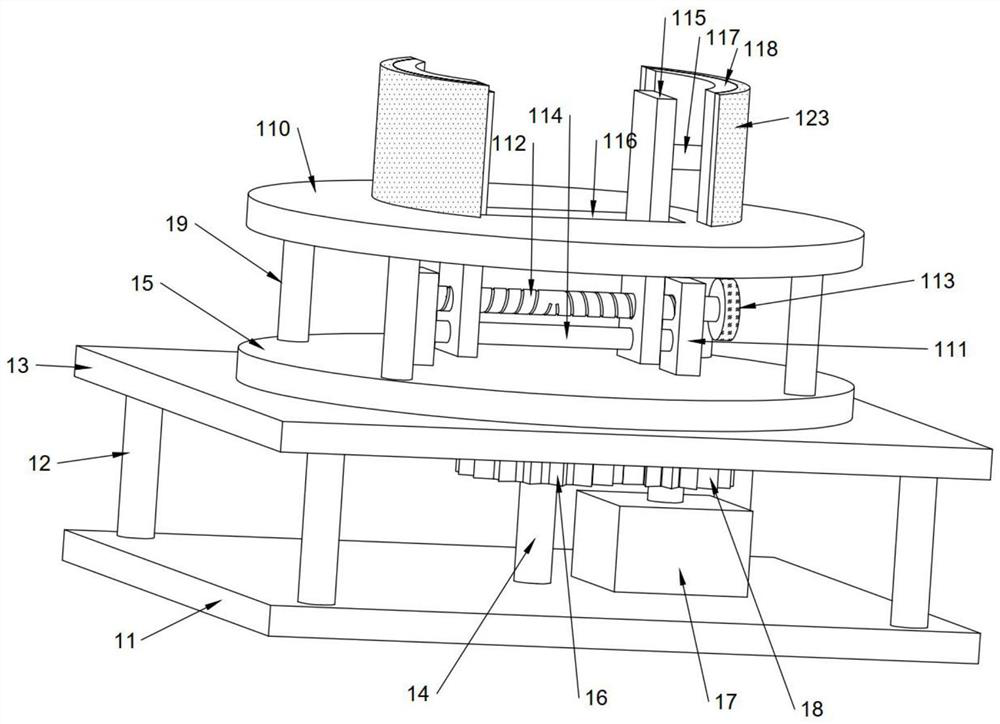

[0046] Such as Figures 1 to 7 As shown, a degree of freedom printing base of an SLM device includes a printing base, a rotating drive mechanism and a lifting drive mechanism;

[0047] The printing base includes a base connecting part and a base body; the base connecting part plays a role of connection and fixing; the base body extends in a strip shape, and the circumferential surface in the extending direction is a printing supporting surface;

[0048] The rotation driving mechanism is connected to the connecting part of the base, and is used to drive the printing base to rotate;

[0049] The upper part of the lifting drive mechanism is connected to the rotation drive mechanism, and the lifting direction of the lift drive mechanism is perpendicular to the axial direction of the rotating rod of the rotation drive mechanism;

[0050] The rotary driving mechanism includes a bottom plate, the four corners of the top of the bottom plate are fixed with support legs, the top of the...

Embodiment 2

[0052] Such as Figures 1 to 7 As shown, a degree of freedom printing base of an SLM device includes a printing base, a rotating drive mechanism and a lifting drive mechanism;

[0053] The printing base includes a base connecting part and a base body; the base connecting part plays a role of connection and fixing; the base body extends in a strip shape, and the circumferential surface in the extending direction is a printing supporting surface;

[0054] The rotation driving mechanism is connected to the connecting part of the base, and is used to drive the printing base to rotate;

[0055] The upper part of the lifting drive mechanism is connected to the rotation drive mechanism, and the lifting direction of the lift drive mechanism is perpendicular to the axial direction of the rotating rod of the rotation drive mechanism;

[0056] the rotary drive mechanism, see Figures 2 to 5 , including the base plate, the four corners of the top of the base plate are fixed with support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com