Anti-rust equipment for bearing

A technology of equipment and bearings, which is applied in the field of bearing antirust equipment, can solve the problems of easy rusting of bearings, etc., and achieve the effects of reducing rust, reducing normal use, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

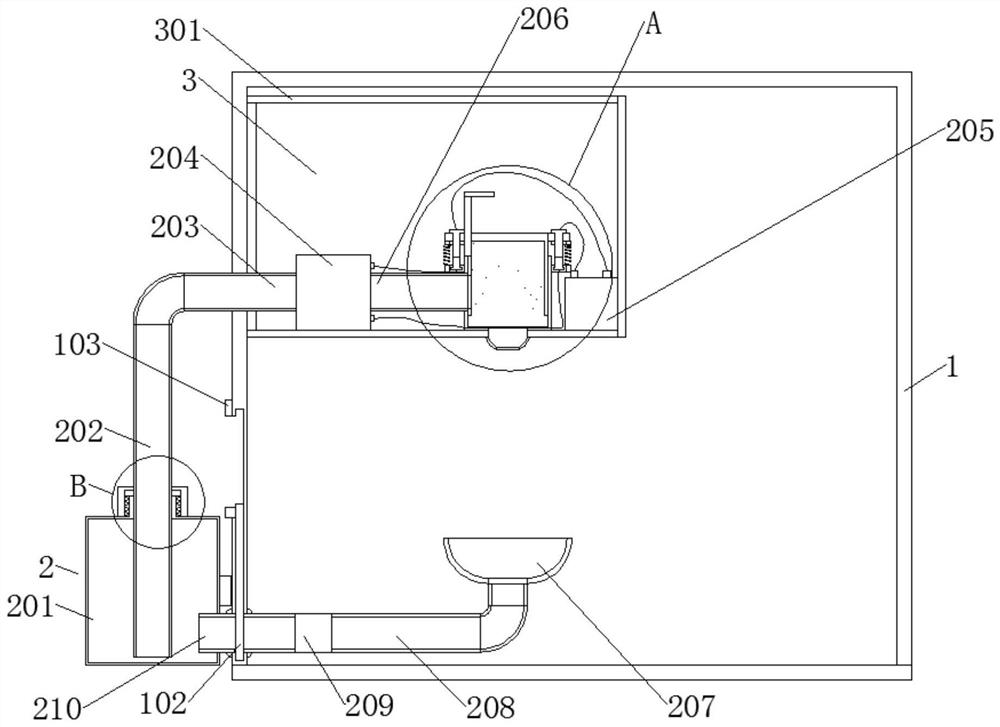

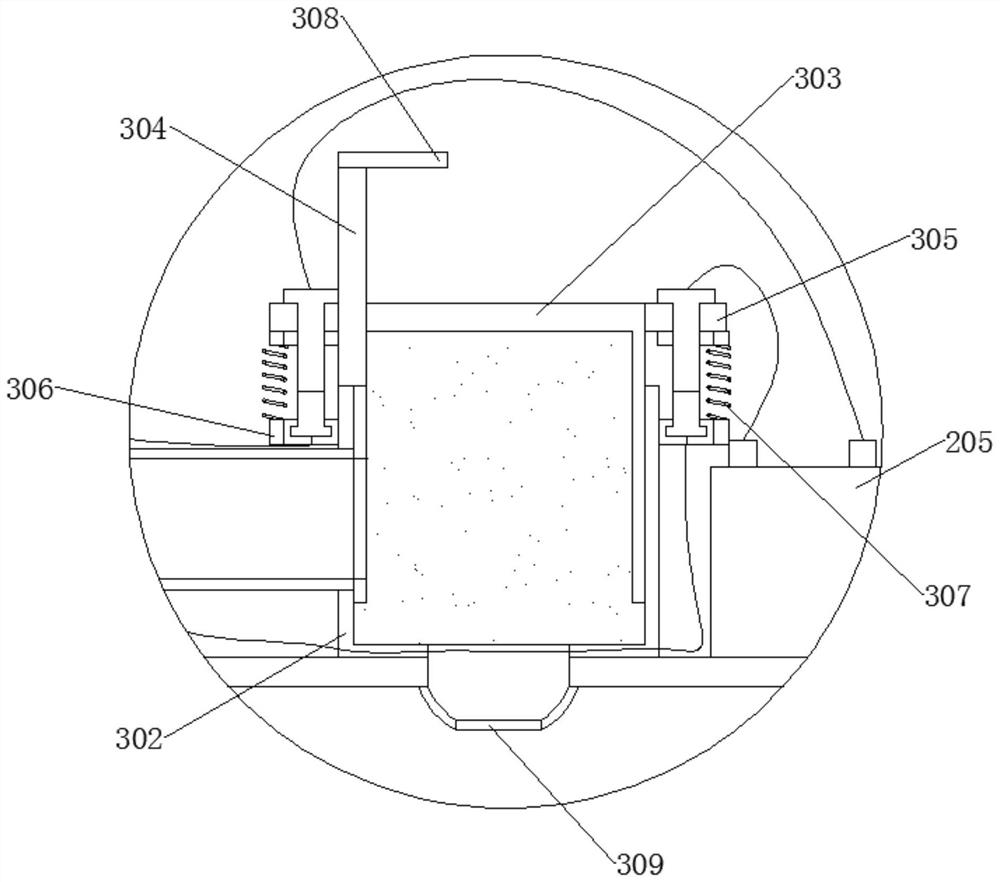

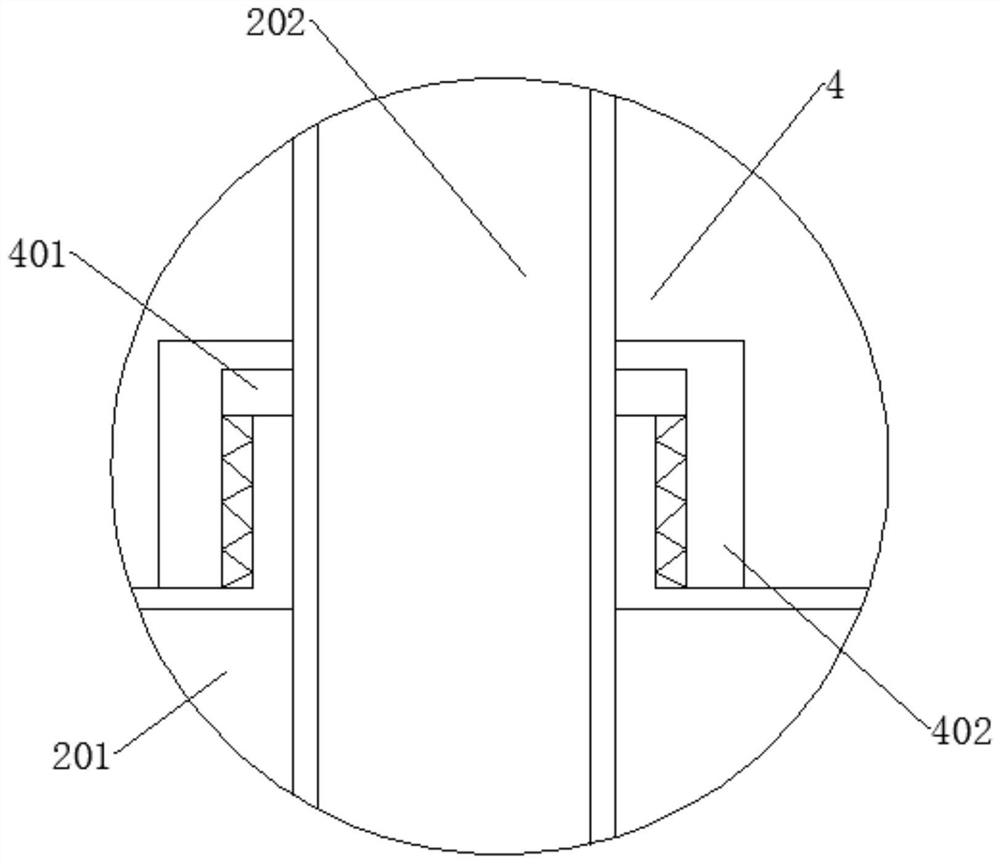

[0023] The invention discloses a bearing antirust device, referring to Figure 1-Figure 4 As shown, including the device body 1, the outer wall of the device body 1 is connected with an oil storage tank clamp 101, which is convenient for fixing the oil storage tank 201. The oil storage tank clamp 101 is provided with an oil delivery mechanism 2 connected with a drip The oil mechanism 3 and the oil delivery mechanism 2 are provided with a connecting mechanism 4. The oil dripping mechanism 3 includes a casing 301. The casing 301 is arranged on the inner side wall of the device body 1, which is convenient for placing the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com