Automatic dust separation and purification control method and system

An automatic separation and dust technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as health hazards, easy deposition in human lungs, shortening the life of electronic equipment, etc., to achieve dynamic follow-up Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

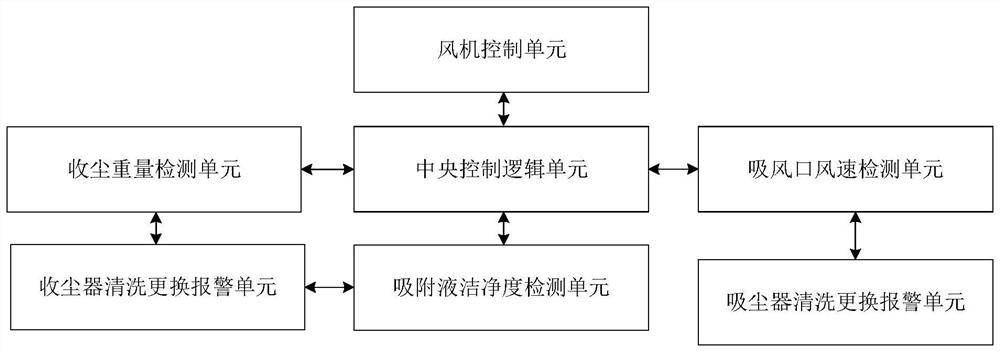

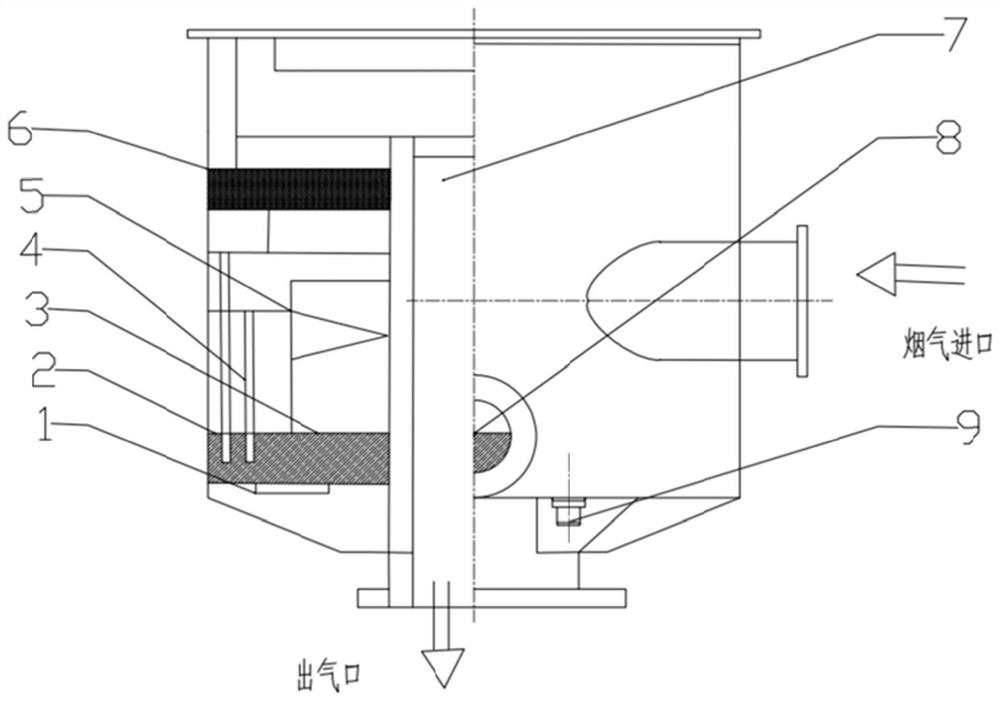

[0036] Such as figure 1 Shown is a schematic structural diagram of a dust automatic separation and purification control system provided by an embodiment of the present invention, including: a central control logic unit, a fan control unit, an adsorption liquid cleanliness detection unit, a dust collection weight detection unit, and a suction port wind speed detection unit , Dust collector cleaning and replacement alarm unit and vacuum cleaner cleaning and replacement alarm unit;

[0037] The output end of the central control logic unit is respectively connected with the signal input end of the fan control unit, the cleanliness detection unit of the adsorption liquid, the dust collection weight detection unit and the wind speed detection unit of the suction port; the dust collection weight detection unit is connected with the dust collector cleaning and replacement alarm unit Connection, the dust collector cleaning and replacement alarm unit is connected to the adsorption liqui...

Embodiment 2

[0048] Such as Figure 4 Shown is a schematic flowchart of a dust automatic separation and purification control method provided by an embodiment of the present invention, including:

[0049] The central control logic unit controls the fan control unit, and then the fan control unit controls the fan to start according to the set fan operating speed;

[0050] The wind speed of the suction port is detected by the wind speed detection unit of the suction port; the dust collection weight is detected by the dust collection weight detection unit; the cleanliness of the adsorption liquid is detected by the adsorption liquid cleanliness detection unit;

[0051] The central control logic unit judges whether it is necessary to clean and replace the dust collection device, clean and replace one or more of the dust collection device and the adsorption liquid according to the detected wind speed of the suction port, the dust collection weight and the cleanliness of the adsorption liquid, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com