Non-contact online cleaning detection and analysis system, device and analysis method

A non-contact, analysis system technology, applied in the field of cleaning detection and analysis system, can solve the problems of harsh detection environment, low measurement accuracy, and long cleaning time of hot rolling transmission equipment, and achieve the effect of intelligent control and rapid adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

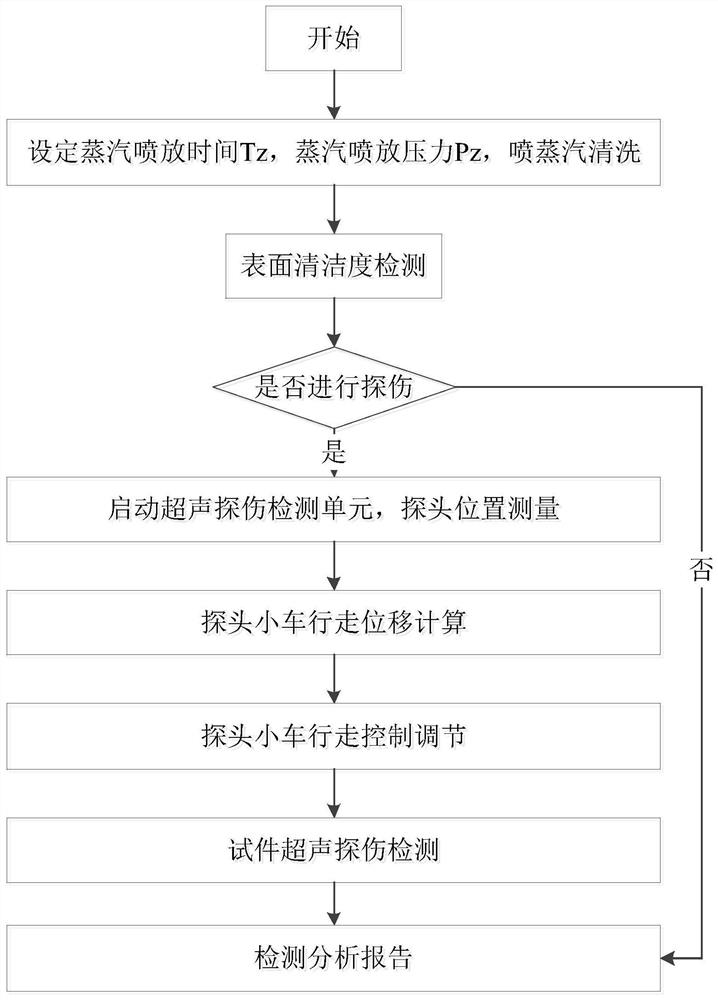

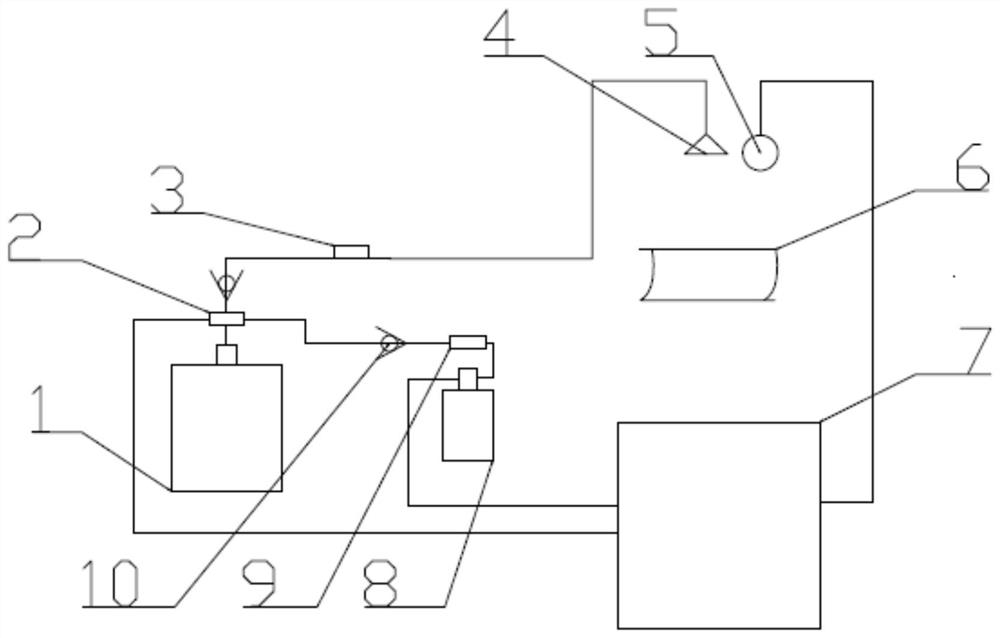

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

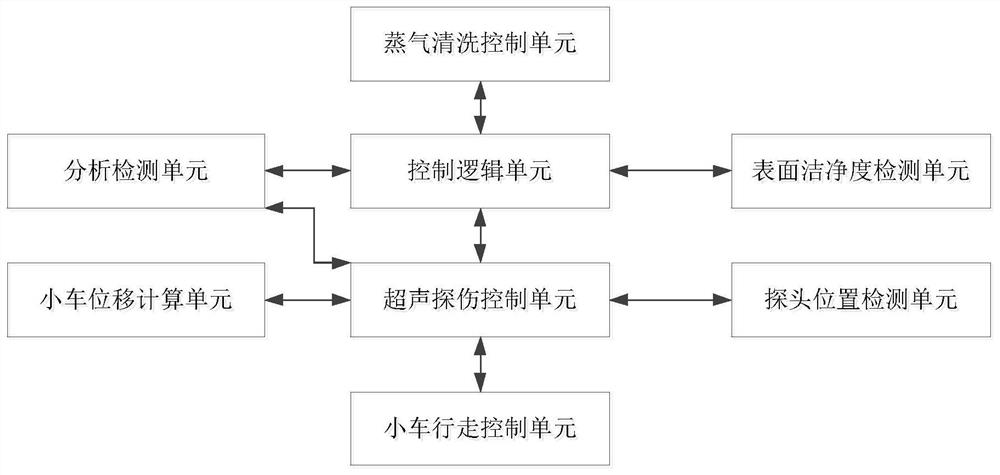

[0033] as attached figure 1 As shown, a non-contact online cleaning detection and analysis system includes a control logic unit, the control logic unit is connected with the steam cleaning control unit, the surface cleanliness detection unit, the ultrasonic flaw detection control unit, and the analysis and detection unit, and the ultrasonic flaw detection control unit is respectively It is connected with the probe position detection unit, the trolley walking control unit, the trolley displacement calculation unit, and the analysis and detection unit.

[0034] The output terminal of the control logic unit is connected with the signal input terminals of the steam cleaning control unit, the ultrasonic flaw detection control unit, and the flaw detection analysis and detection unit to realize data exchange between the surface cleanliness detection m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com