Intelligent control system and method for cigarette silk making process

A control system and tobacco manufacturing technology, applied in the tobacco industry, can solve the problems of inability to realize process parameter prediction, early warning, recommendation and learning, inability to realize precise control of moisture in the entrance of dried shredded silk, and poor interaction of process parameters, etc., to achieve optimal intelligence Control method and ability, prevent tobacco moisture instability, increase the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

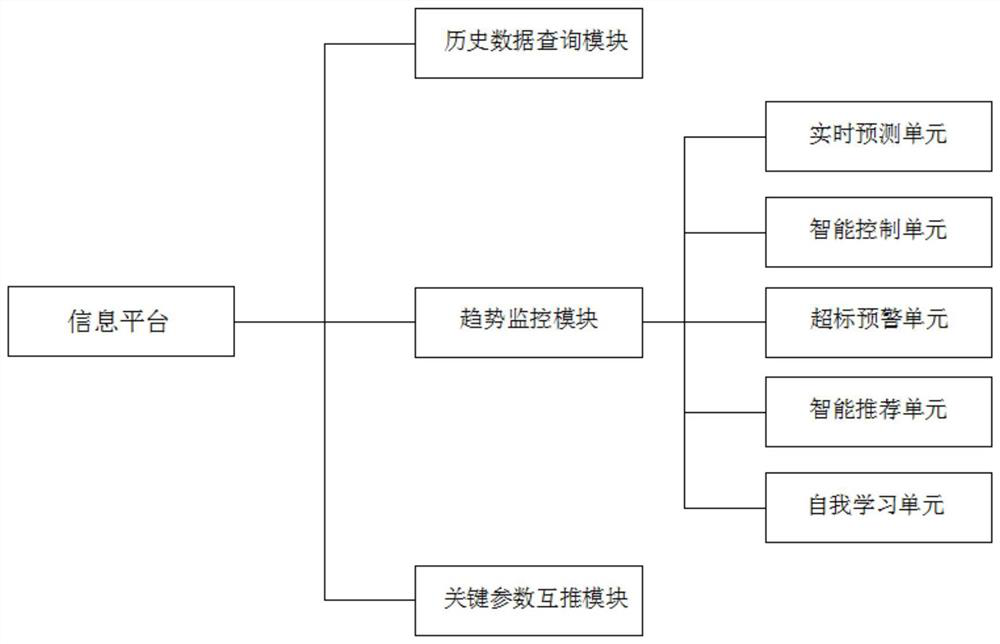

[0063] refer to figure 1 , the present embodiment is an intelligent control system for cigarette shreds, including an information platform, which stores historical production data: historical production data includes historical batch parameters, parameter relationships, key parameters (production key indicators, such as Moisture at the outlet of feeding and regaining moisture, moisture at the outlet of hot air moistening leaves, moisture at the inlet of dried silk, etc.) and historical forecast data, actual parameter data (measured data obtained through monitoring sensors, such as moisture meters, flow meters, electronic scales, etc.), time of day, season Influencing factors such as changing ambient temperature and humidity and other relevant historical production data that can be used in the intelligent control system.

[0064] The system also includes a trend monitoring module, a key parameter prediction module and a historical data query module connected to the information ...

Embodiment 2

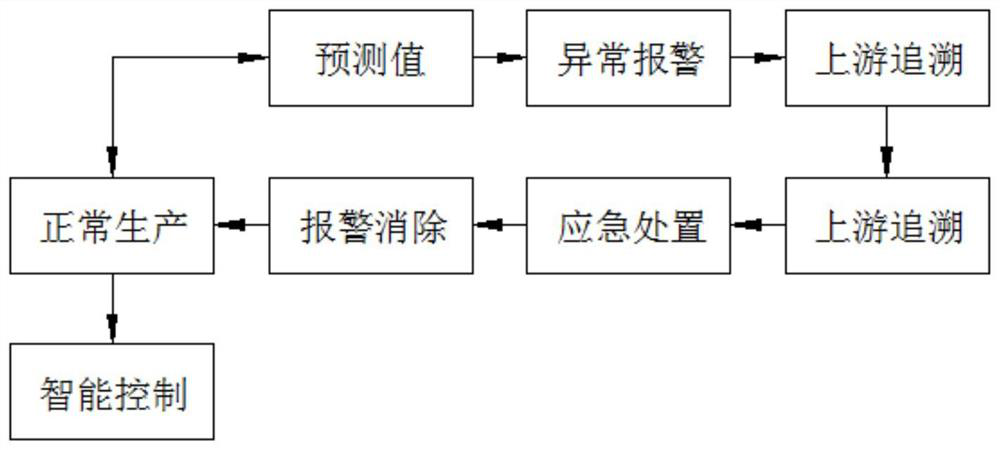

[0125] An intelligent control method for tobacco shredded process. This method is applied to the intelligent control system for tobacco shredded process described in Example 1, which includes the following steps:

[0126] Step 1, data collection

[0127] Data source: corresponding historical production data in the silk production line information management system;

[0128] Step 2: Predictive Model Establishment

[0129] Combining multiple regression analysis algorithms and neural network algorithms, a nested production parameter prediction model is established in stages according to the process sections to predict the production parameters of each section;

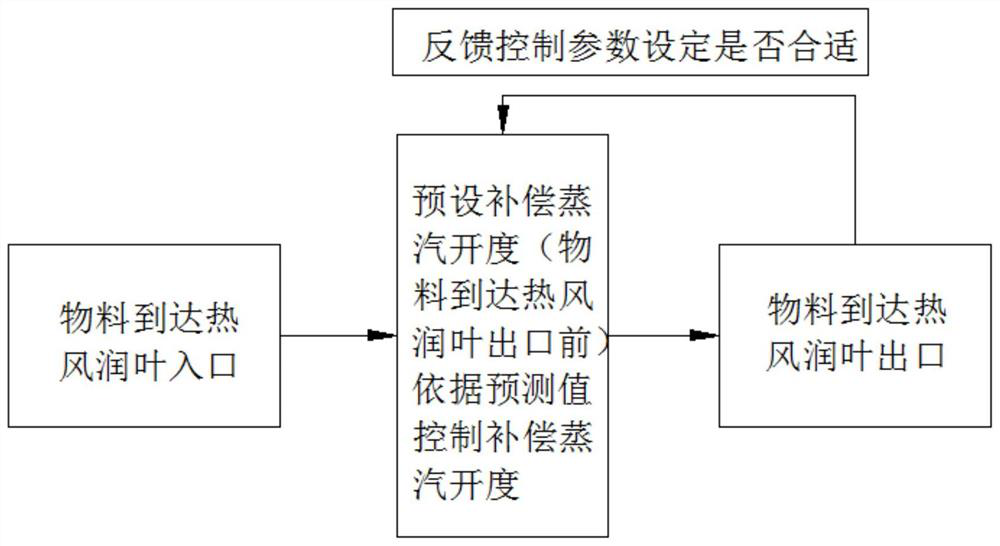

[0130] Step 3, control model establishment

[0131] Based on the predicted value of step 2, through the neural network algorithm, the intelligent control model is established in stages according to the process section, and the control parameters of each section are predicted, and the equipment in each process section is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com