Overload protection arrangement

A technology of overload protection and overvoltage protection, applied in the direction of protection switch operation/release mechanism, electrical components, sustainable manufacturing/processing, etc., can solve problems such as damaged materials and devices, fire hazards, damaged components, etc., to achieve simple and reliable separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

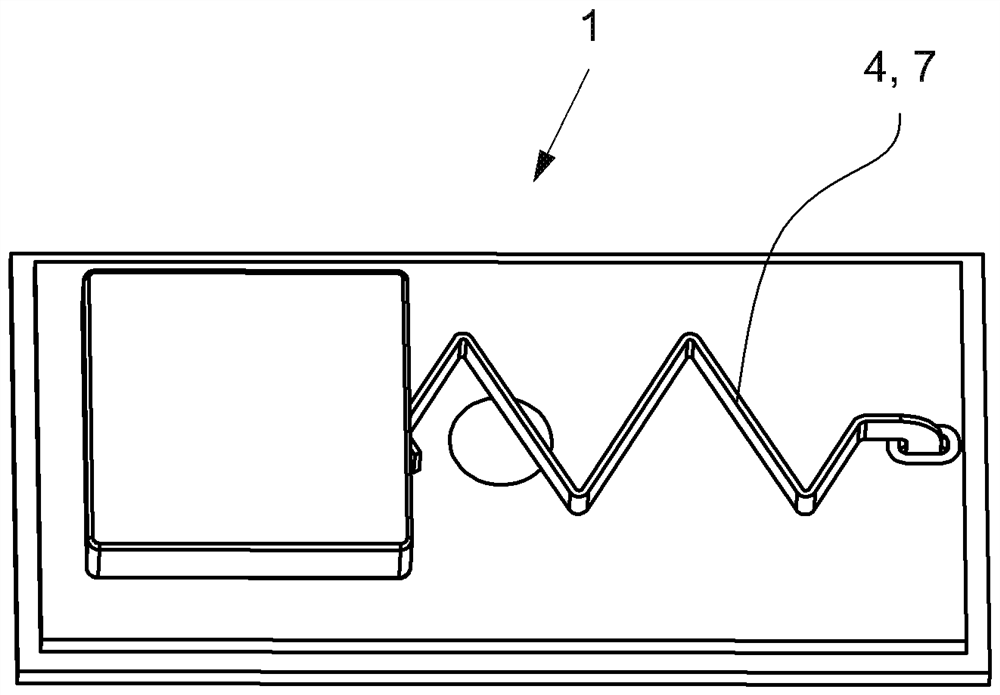

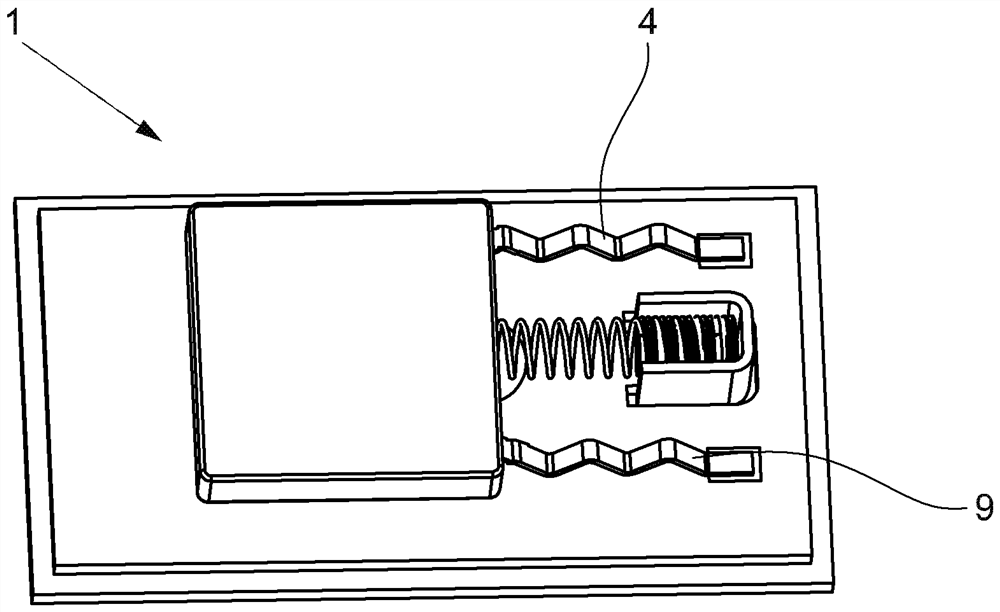

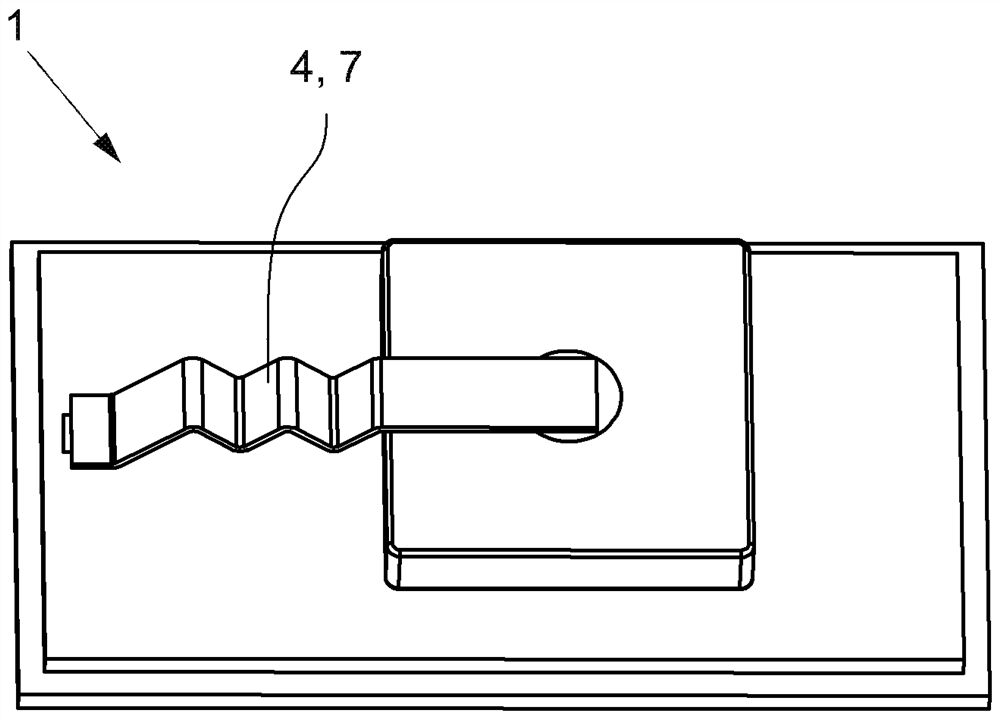

[0048] figure 1 A first exemplary embodiment of an overload protection arrangement 1 for protecting an overvoltage protection structural element 2 is shown in section. The overload protection assembly 1 comprises a structural overvoltage protection element 2 , which is electrically connected via a first connection element 3 and via a second connection element 4 to a current conducting element arranged on a carrier 5 , which is designed here as a printed circuit board.

[0049] The first coupling element 3 comprises a heat-sensitive contact element 6 in the illustrated embodiment. In detail, in figure 1 The heat-sensitive contact element 6 shown in is designed as a low-temperature solder and thus forms the thermal separation point of the overvoltage protection component 2 . In the event of a thermal overload, the heat-sensitive contact element 6 melts, thereby breaking the mechanical contact formed by the contact element 6.

[0050] connect.

[0051] Furthermore, there is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com