Device for removing an end closure

A sealing part and removal technology, applied in packaging, transportation and packaging, envelope/bag manufacturing machinery, etc., can solve the problems of increasing dust formation, etc., and achieve the effect of simple and reliable opening, simple and reliable removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

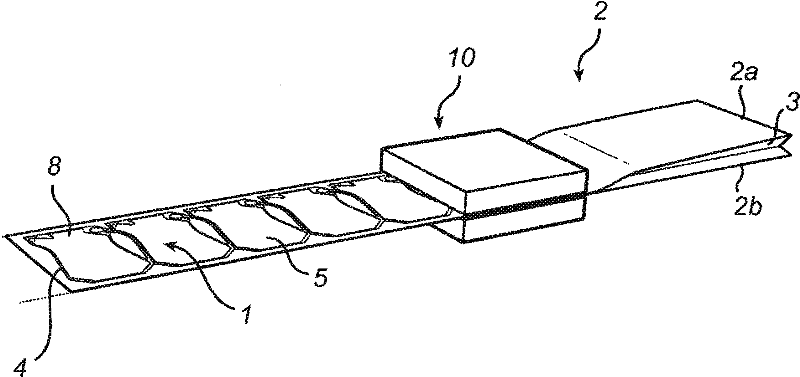

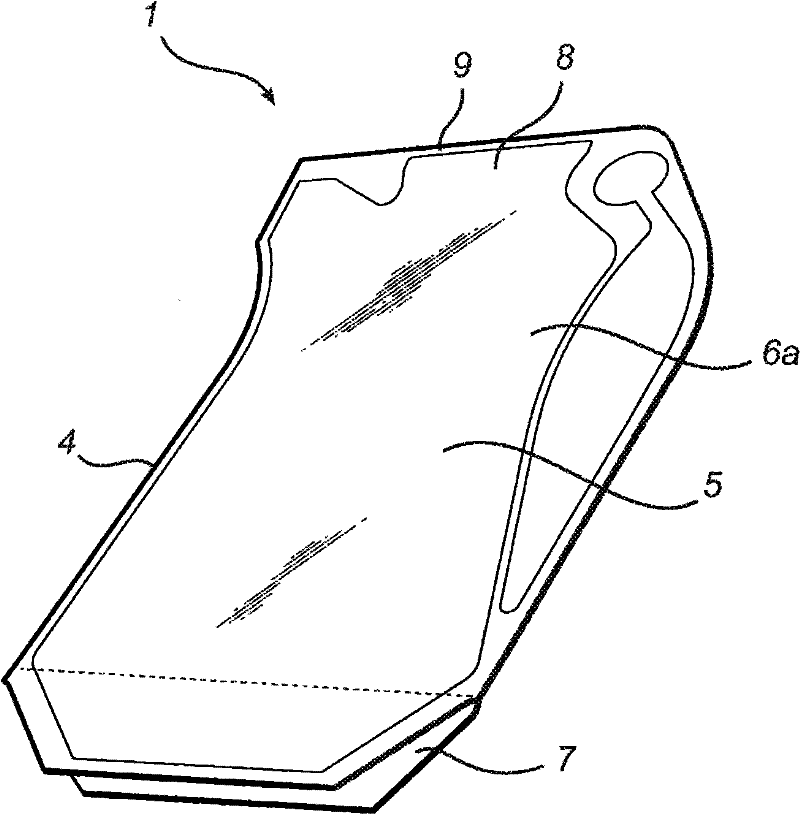

[0043] figure 1 An example of a method for manufacturing the pack 1 of the foldable type is illustrated, which is non-limiting for the present invention. The package 1 is manufactured from an M-folded packaging roll 2 comprising two opposing side wall-shaped parts 2a, 2b and a folded bottom wall-shaped part 3 arranged between the side wall-shaped parts 2a, 2b. The packaging roll 2 is preferably produced from a deformable layered packaging material. The packaging material may comprise a core layer of polyolefin material. The core layer may further comprise a filler of mineral material, which may advantageously consist of chalk (calcium carbonate).

[0044] To form the package 1 , the two side wall-shaped parts 2 a , 2 b and the bottom wall-shaped part 3 are brought together in a tool 10 . The tool 10 connects the parts 2 a , 2 b , 3 along a connecting part 4 for delimiting the cavity 5 . The tool 10 can connect the connection part 4 eg by means of heat, pressure, ultrasound...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com