Relay setting packer and method

A technology for packers and connecting pipes, which is applied in sealing/isolation, earthwork drilling, wellbore/well components, etc., and can solve the problems of increasing operating costs and development costs, easy failure of rubber cartridge seals, and failure of pipe strings, etc. problems, to achieve the effect of reducing operating costs and oil and gas production costs, and improving the production cycle of pipe strings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

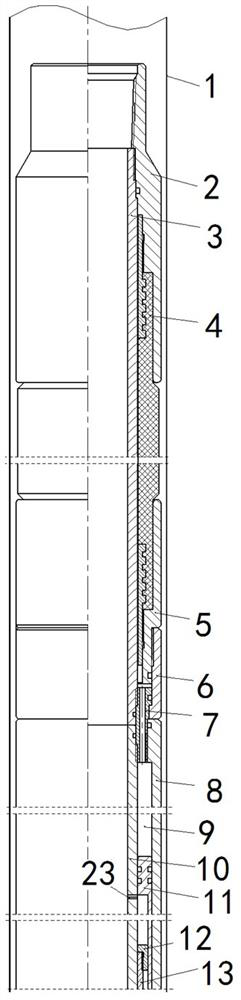

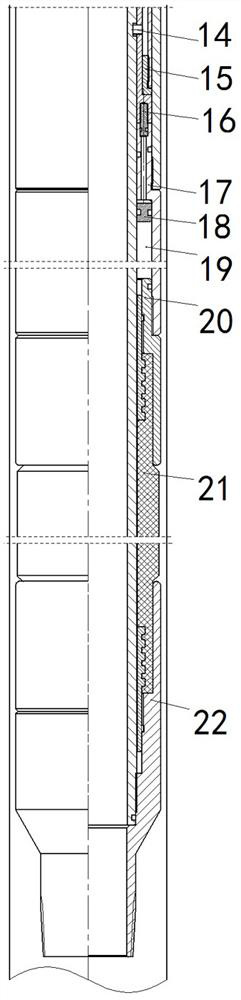

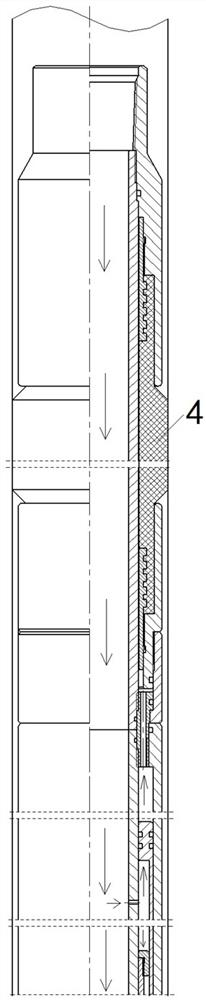

[0025] Example 1, refer to figure 1 and 2 , a relay setting packer mentioned in the present invention includes an upper joint 2, an upper central pipe 3, an upper rubber barrel 4, a pressure ring 5, a pull ring 6, a pressure transmission pipe 7, an upper cylinder liner 8, an upper Hydraulic cylinder 9, lower central pipe 10, upper piston 11, pressure cap 12, connecting pipe 13, shear nails 14, retaining ring 15, plunger 16, lower cylinder sleeve 17, lower piston 18, lower hydraulic cylinder 19, connecting sleeve 20 , the lower rubber cylinder 21, the lower joint 22, the upper end of the upper central tube 3 is provided with an upper joint 2, the lower outer wall of the upper central tube 3 is provided with a pressure ring 5 and a pull ring 6, and the upper joint 2 and the pressure ring 5 are provided with There is a gluing cylinder 4 in between, and the upper piston 11 moves up and pushes the gluing cylinder 4 to expand;

[0026] The lower end of the upper center pipe 3 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com