Suspension connecting joint for large-span cantilever steel truss and construction method thereof

A technology of long-span cantilevering and connecting nodes, which is applied in the direction of load-bearing elongated structural members, special structures, buildings, etc., and can solve problems such as difficulty in guaranteeing construction accuracy, high cost of supporting tire frames, and complex node spaces. Achieve the effects of low design and construction difficulty, convenient pre-arching value, and high safety redundancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention are described in detail below through the examples, and the following examples are only exemplary, and can only be used to explain and illustrate the technical solutions of the present invention, but cannot be construed as limitations to the technical solutions of the present invention.

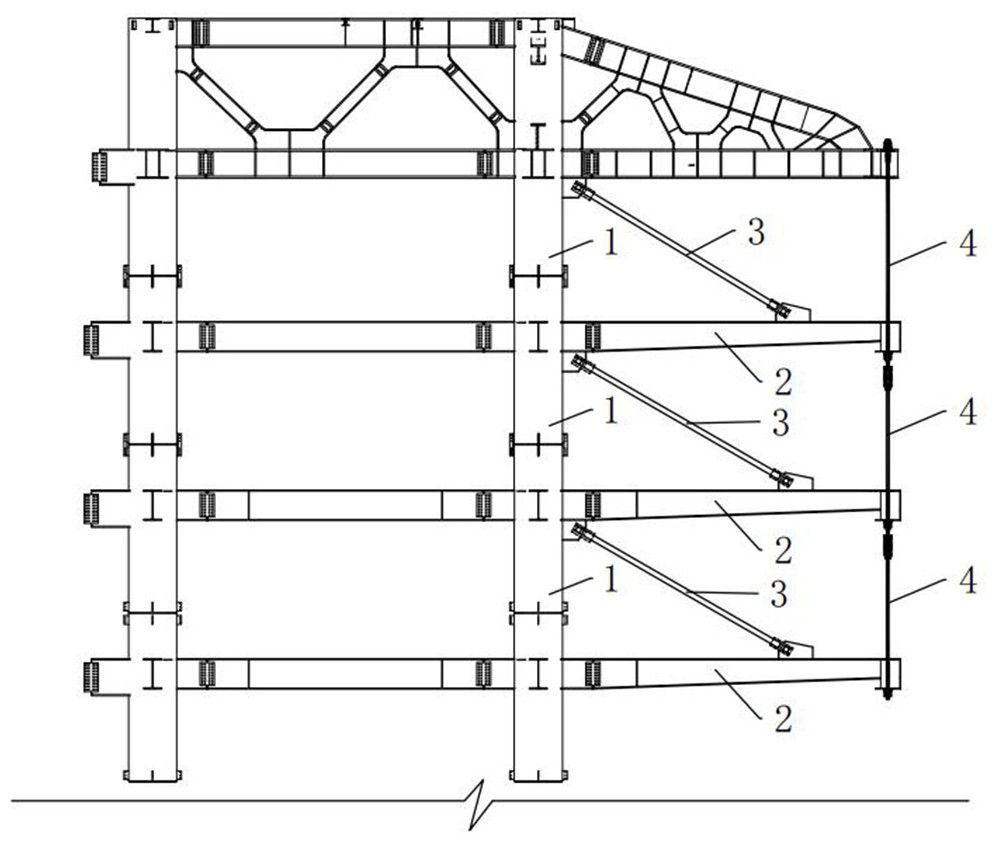

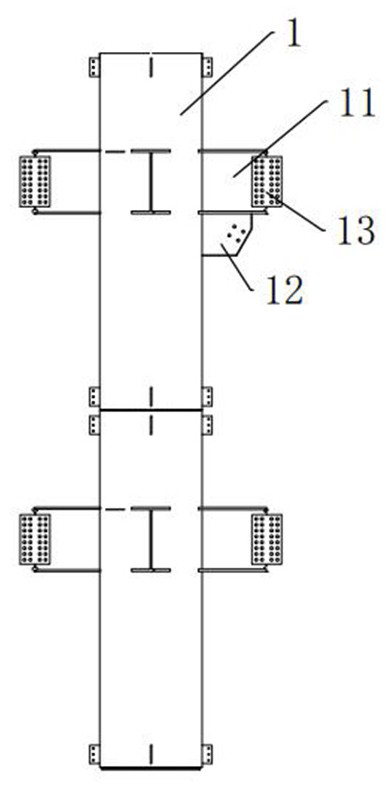

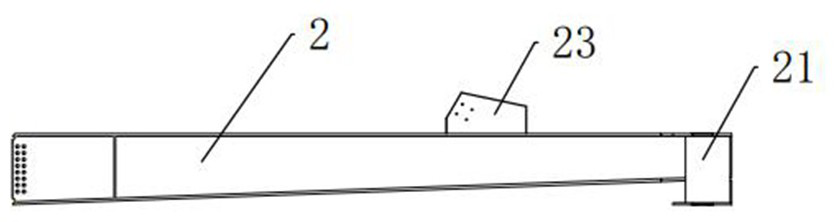

[0039] Such as figure 1 , a suspension connection node for a large-span cantilevered steel truss, including a steel pipe column 1, a cantilevered main beam 2, a temporary steel tie rod 3 and a fixed steel tie rod 4, such as figure 2 , the steel pipe column 1 is arranged vertically on the edge of the main structure, the side end of the steel pipe column 1 is fixedly welded with a steel corbel 11, and the bottom end of the steel corbel 11 is fixedly provided with a vertical column ear plate 12, and the column ear plate 12 is in the shape of a perforated plate, and the end of the steel corbel 11 away from the steel pipe column 1 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com