A kind of synthetic method of 1-(2-dimethylaminoethyl)-1h-5-mercapto-tetrazolium

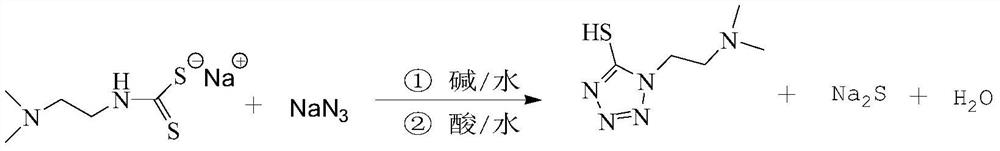

A technology of -1H-5-, dimethylaminoethyl, which is applied in the field of synthesis of 1--1H-5-mercapto-tetrazolium, can solve the problem of less introduction of synthesis process, low yield of production process and complex equipment and other problems, to achieve the effects of environmental protection and easy waste salt treatment, avoiding biodegradation, and simple and easy post-treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

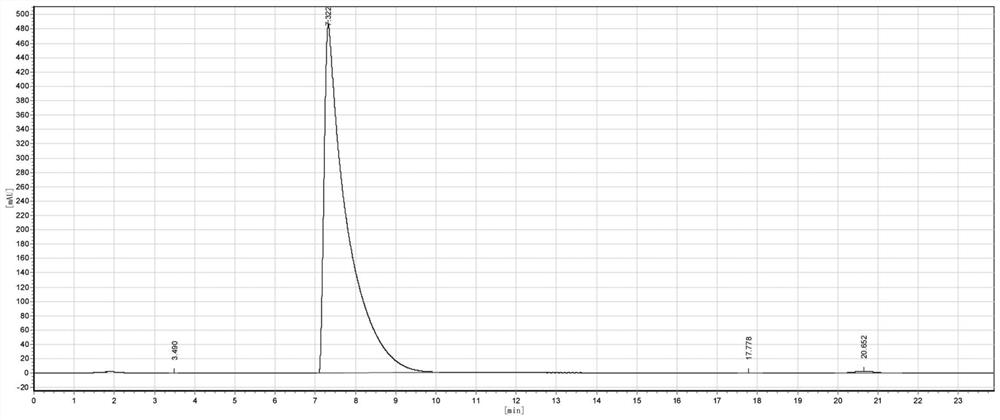

Embodiment 1

[0026] Add 40g of N,N-dimethylethylenediamine sodium dithiocarboxylate and 160g of reaction solvent water to a 500mL four-necked bottle in turn, mix them, and slowly add catalysts to the reaction system with stirring, that is, the mass fraction is 30% The concentration of sodium hydroxide solution is 57.3g, then 13g of sodium azide is added to the reaction system, the temperature is raised to 90°C and the temperature is kept for 16 hours. Afterwards, use 43.3g of hydrochloric acid with a mass fraction of 36% to neutralize the solution until the pH of the solution is 4, stir for 30 minutes evenly, then cool down to 8°C, filter with suction, and the filter cake is 1-(2-dimethylaminoethyl)-1H-5 -Mercapto-tetrazolium crude product, 1-(2-dimethylaminoethyl)-1H-5-mercapto-tetrazolium crude product with 3 times the volume of recrystallization solution, that is, the mass fraction is 30% toluene / 70% water recrystallization, the recrystallization process is to completely dissolve the c...

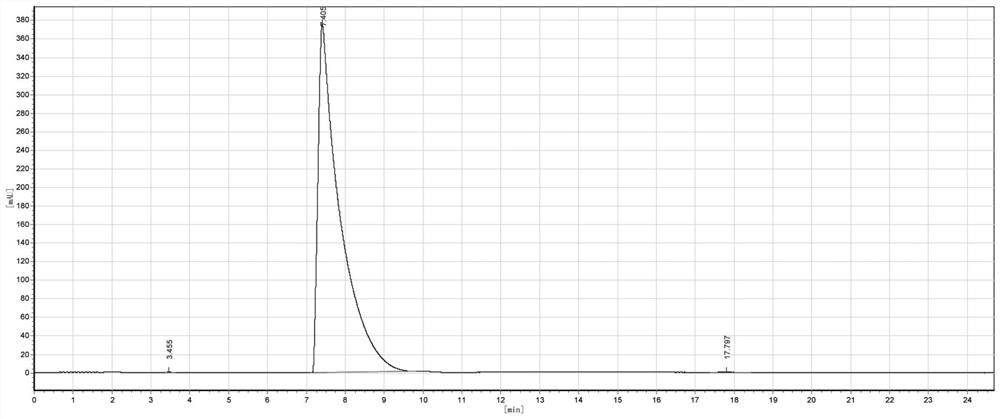

Embodiment 2

[0028] Add 42g of N,N-dimethylethylenediamine sodium dithiocarboxylate and 210g of reaction solvent water to a 500mL four-necked bottle in turn, mix them, and slowly add catalyst to the reaction system with stirring, that is, the mass fraction is 30% The concentration of sodium hydroxide solution is 60g, then 13g of sodium azide is added to the reaction system, the temperature is raised to 85°C and the temperature is kept for 16 hours. Use 45.8g of hydrochloric acid with a mass fraction of 36% to neutralize the solution until the pH of the solution is 5, stir for 30 minutes to be uniform, then cool down to 7°C, filter with suction, and the filter cake is 1-(2-dimethylaminoethyl)-1H-5- Mercapto-tetrazolium crude product, 1-(2-dimethylaminoethyl)-1H-5-mercapto-tetrazolium crude product with 4 times the volume of recrystallization solution, that is, the mass fraction is 35% toluene / 65 % water recrystallization, the recrystallization process is to completely dissolve the crude pro...

Embodiment 3

[0030] Add 44g of N,N-dimethylethylenediamine sodium dithiocarboxylate and 263g of reaction solvent water to a 500mL four-necked bottle in turn, mix them, and slowly add catalysts to the reaction system with stirring, that is, the mass fraction is 30% 63g of sodium hydroxide solution with a concentration of 63g, then add 13g of sodium azide to the reaction system, raise the temperature to 95°C and keep it warm for 17 hours. Afterwards, use 46.3g of sulfuric acid with a mass fraction of 50% to neutralize the solution until the pH of the solution is 5, stir for 30 minutes evenly, then cool down to 10°C, filter with suction, and the filter cake is 1-(2-dimethylaminoethyl)-1H-5 -Mercapto-tetrazolium crude product, 1-(2-dimethylaminoethyl)-1H-5-mercapto-tetrazolium crude product is 40% toluene / 60 with the recrystallization solution of 5 times volume % water recrystallization, the recrystallization process is to completely dissolve the crude product of 1-(2-dimethylaminoethyl)-1H-5-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com