Double-micro-treatment process for treating oilfield produced water

A produced water and micro-treatment technology, applied in the field of water treatment, can solve the problem of unsatisfactory suspended solids content, median particle size of suspended solids and impurity content, aggravating the maintenance and operation burden of water injection station and post-treatment, water injection station and post-treatment Deal with problems such as fouling of equipment and pipes to achieve the effect of avoiding abnormal increase in filter resistance, good water treatment effect, and stable parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

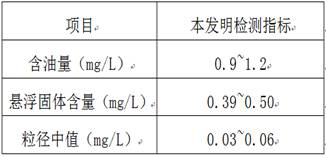

Examples

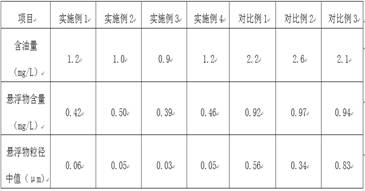

Embodiment 1

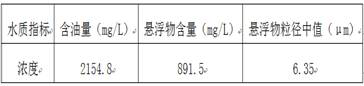

[0049] A double micro-treatment process for treating oilfield produced water, comprising: a pre-treatment step, a micro-swirl air flotation step, a water balance step, and a micro-filtration step.

[0050] The pretreatment step includes a settling step and a filtering step.

[0051] In the settling step, silicon dioxide particles are put into the produced water of the oil field, stirred and settled for 3 hours at a temperature of 50°C.

[0052] The stirring speed is 20 RPM.

[0053] The ratio of oilfield produced water: silicon dioxide particles in parts by weight is 1000:1.

[0054] The silica particles are silica particles immobilized with Pseudomonas aeruginosa and Bacillus subtilis, and the preparation method thereof comprises: treating the silica particles and immobilizing bacteria.

[0055] For the treatment of the silica granules, heat the 20-mesh silica granules to 110°C in a vacuum environment and keep them warm for 10 minutes; place the silica granules in 0.5% sodi...

Embodiment 2

[0080] A double micro-treatment process for treating oilfield produced water, comprising: a pre-treatment step, a micro-swirl air flotation step, a water balance step, and a micro-filtration step.

[0081] The pretreatment step includes a settling step and a filtering step.

[0082] In the settling step, silicon dioxide particles are put into the produced water of the oilfield, stirred and settled for 5 hours at a temperature of 60°C.

[0083] The stirring speed is 30 RPM.

[0084] The ratio of oilfield produced water: silicon dioxide particles in parts by weight is 1000:1.

[0085] The silica particles are silica particles immobilized with Pseudomonas aeruginosa and Bacillus subtilis, and the preparation method thereof comprises: treating the silica particles and immobilizing bacteria.

[0086] For the treatment of the silica particles, heat the 20-mesh silica particles to 130°C in a vacuum environment and keep the heat for 12 minutes; place the silica particles in 1% sodiu...

Embodiment 3

[0111] A double micro-treatment process for treating oilfield produced water, comprising: a pre-treatment step, a micro-swirl air flotation step, a water balance step, and a micro-filtration step.

[0112] The pretreatment step includes a settling step and a filtering step.

[0113] In the settling step, silicon dioxide particles are put into the produced water of the oil field, stirred and settled for 4 hours at a temperature of 55°C.

[0114] The stirring speed is 30 RPM.

[0115] The ratio of oilfield produced water: silicon dioxide particles in parts by weight is 1000:1.

[0116] The silica particles are silica particles immobilized with Pseudomonas aeruginosa and Bacillus subtilis, and the preparation method thereof comprises: treating the silica particles and immobilizing bacteria.

[0117] For the treatment of the silica particles, heat the 25-mesh silica particles to 120°C in a vacuum environment and keep the temperature for 12 minutes; place the silica particles in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com