Automatic packaging device for bread processing

An automatic and bread-based technology, applied in packaging, transportation packaging, food packaging, etc., can solve the problems of crowded production lines, low packaging efficiency, and single function, and achieve the effects of saving labor costs, improving packaging efficiency, and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

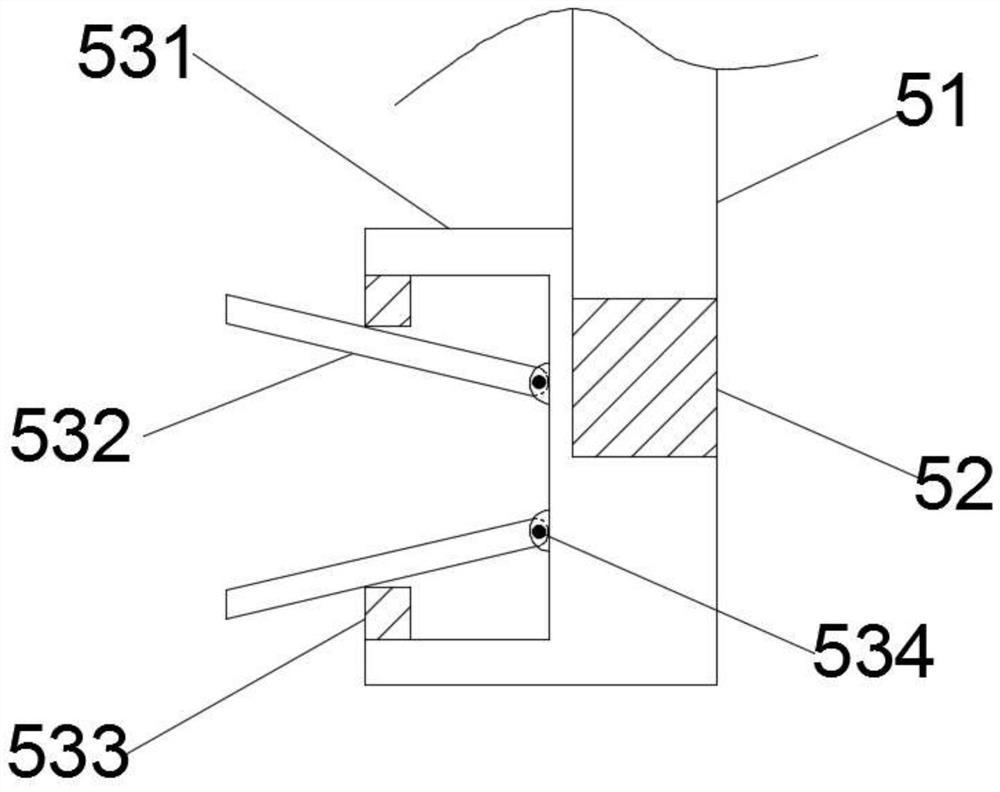

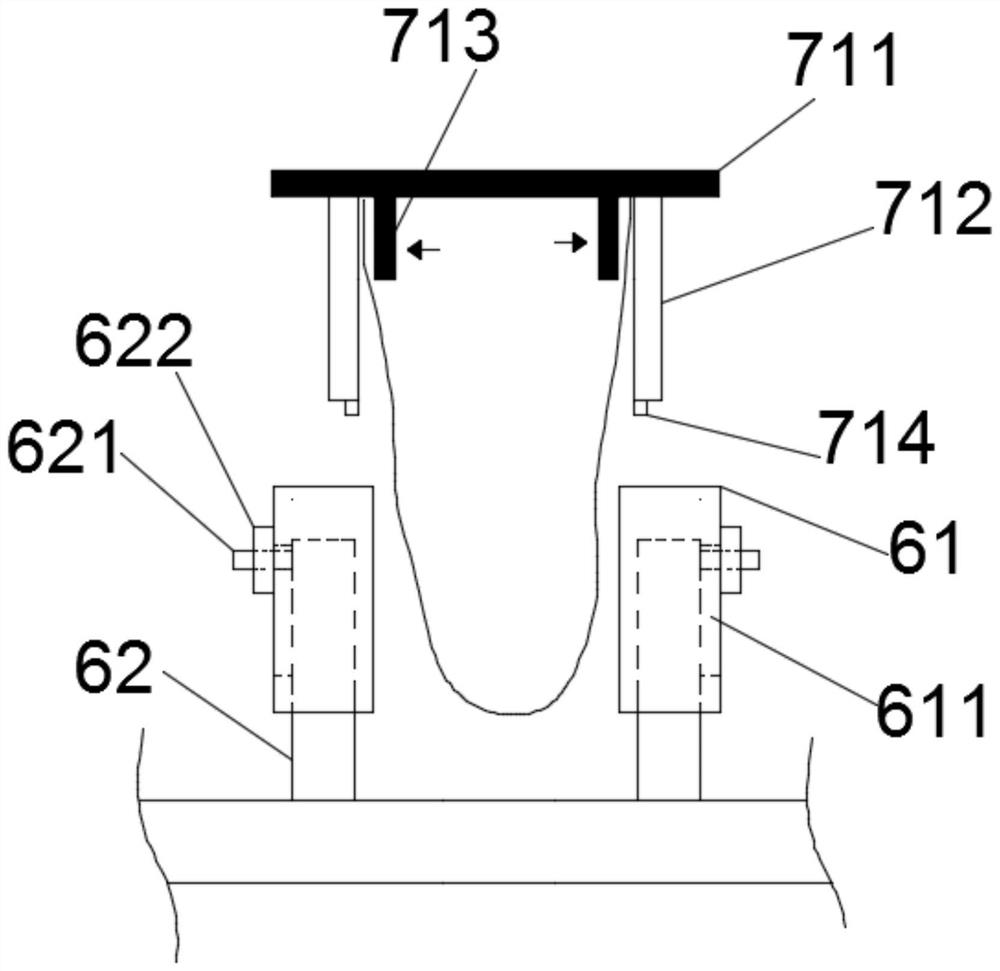

[0028] see figure 1 , figure 2 and Figure 5 , the present invention provides a technical solution: an automatic packaging device for bread processing, including No. 1 transmission line, No. 2 transmission line, bag stretching mechanism 7 and heat sealing mechanism, No. 1 transmission line and No. 2 transmission line both include support frame, driving roller 2 and a plurality of driven rollers 3, a transmission motor 1 is installed on the support frame, the output end of the transmission motor 1 is connected with the driving roller 2, and the driven rollers 3 are connected with the driving roller 2 through the transmission belt 4, the driving roller 2, the driving roller The moving rollers 3 are all connected to the support frame through bearings; the No. 1 transmission line is also provided with a grabbing manipulator 5, which includes a No. 1 horizontal electric telescopic rod 51, a No. 1 vertical electric telescopic rod 52 and a grabbing hand 53. The end of No. 1 horizo...

Embodiment 2

[0033] see figure 1 and image 3 , the present invention provides a technical solution: an automatic packaging device for bread processing, including No. 1 transmission line, No. 2 transmission line, bag stretching mechanism 7 and heat sealing mechanism, No. 1 transmission line and No. 2 transmission line both include support frame, driving roller 2 and a plurality of driven rollers 3, a transmission motor 1 is installed on the support frame, the output end of the transmission motor 1 is connected with the driving roller 2, and the driven rollers 3 are connected with the driving roller 2 through the transmission belt 4, the driving roller 2, the driving roller The moving rollers 3 are all connected to the support frame through bearings; the No. 1 transmission line is also provided with a grabbing manipulator 5, which includes a No. 1 horizontal electric telescopic rod 51, a No. 1 vertical electric telescopic rod 52 and a grabbing hand 53. The end of No. 1 horizontal electric ...

Embodiment 3

[0039] see figure 1 and Figure 4 , the present invention provides a technical solution: an automatic packaging device for bread processing, including No. 1 transmission line, No. 2 transmission line, bag stretching mechanism 7 and heat sealing mechanism, No. 1 transmission line and No. 2 transmission line both include support frame, driving roller 2 and a plurality of driven rollers 3, a transmission motor 1 is installed on the support frame, the output end of the transmission motor 1 is connected with the driving roller 2, and the driven rollers 3 are connected with the driving roller 2 through the transmission belt 4, the driving roller 2, the driving roller The moving rollers 3 are all connected to the support frame through bearings; the No. 1 transmission line is also provided with a grabbing manipulator 5, which includes a No. 1 horizontal electric telescopic rod 51, a No. 1 vertical electric telescopic rod 52 and a grabbing hand 53. The end of No. 1 horizontal electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com