Polyester composite waterproof coiled material and preparation method thereof

A waterproofing membrane and polyester technology, which is applied in the direction of winding strips, packaging material feeding devices, packaging/bundling items, etc., which can solve the problems of dampness in the stacking of embedded paper tubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0037] As shown in the figure, a method for preparing a polyester composite waterproof membrane, the method includes the following steps:

[0038] Step 1. Composite polyester fiber cotton and PVC rubber to obtain polyester composite waterproof membrane;

[0039] Step 2, placing the paper tube on the polyester composite waterproof membrane preparation device;

[0040] Step 3, roll a layer of plastic film on the outer surface of the paper tube to obtain the tube core;

[0041] Step 4, winding the polyester composite waterproof membrane on the core;

[0042] The method for preparing polyester composite waterproof membrane also includes a preparation device for polyester composite waterproof membrane;

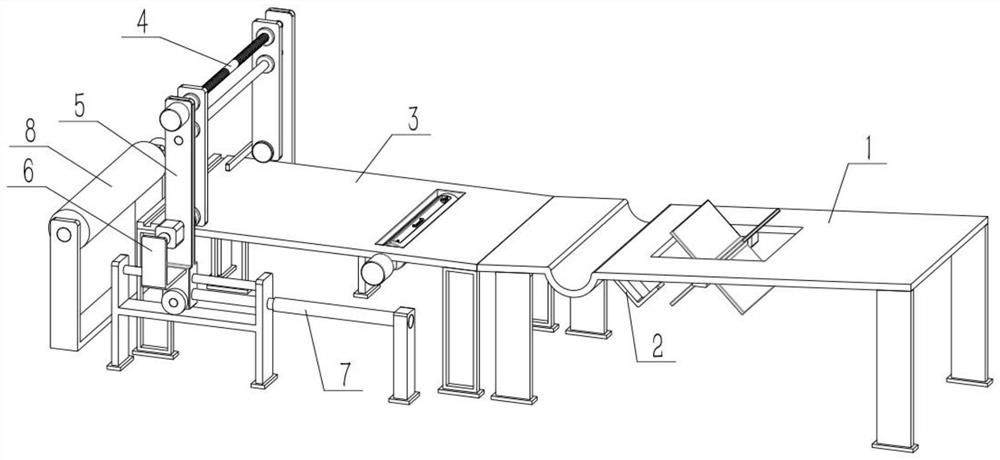

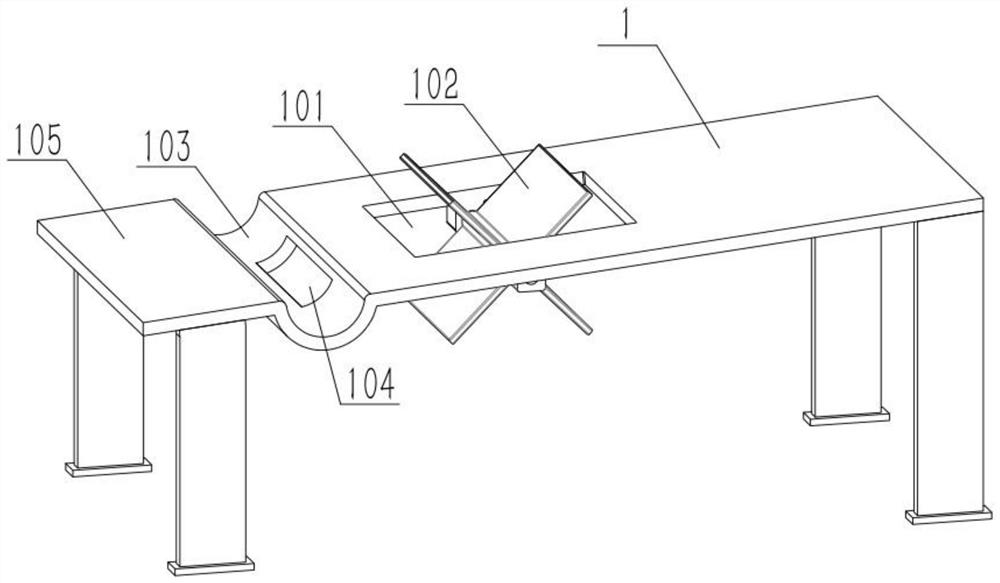

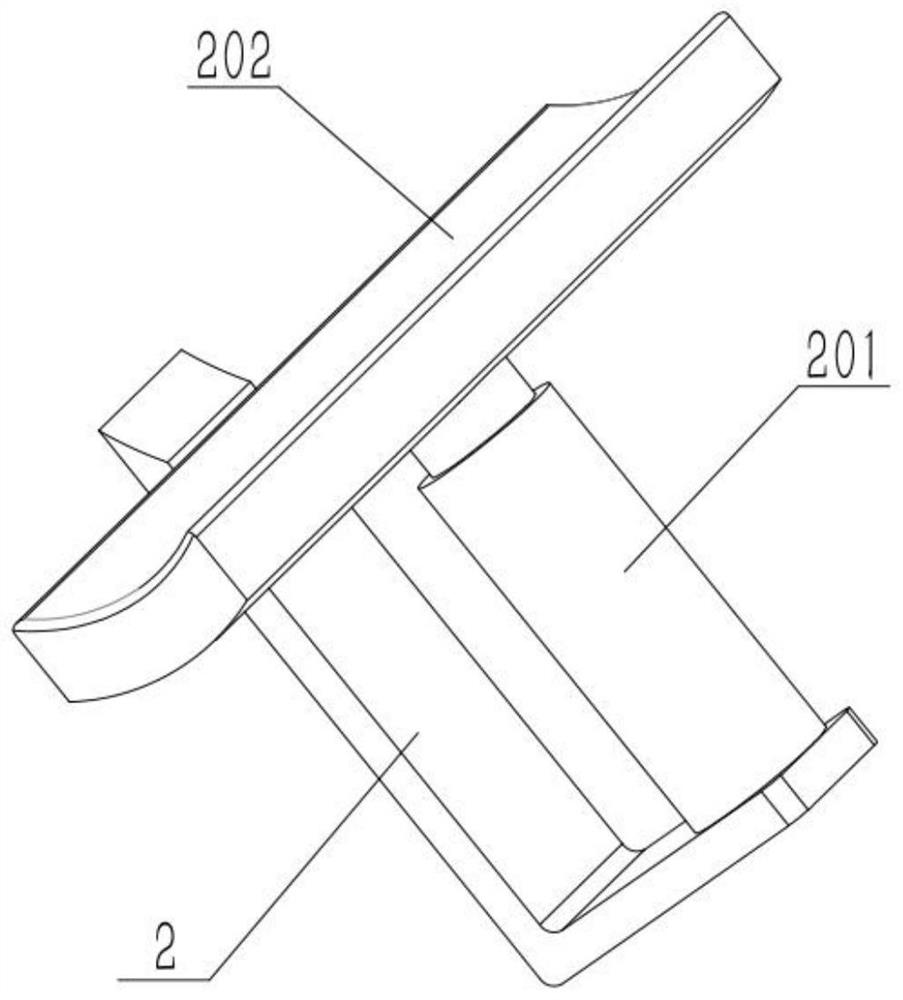

[0043] The polyester composite waterproof membrane preparation device includes an inclined table 1, a port I 101, a blade 102, an arc portion 103, an port II 104, a speeding table 105, a frame I2, an electric push rod I 201 and an arc pusher 202, and the inclined table 1 is prov...

specific Embodiment approach 2

[0045] As shown in the figure, the polyester composite waterproof membrane preparation device also includes a processing table 3, a two-way screw 4, a round steel I 401, a plate frame 402 and an adjusting frame 5, and the right end of the processing table 3 is connected to the left end of the inclined table 1, Two plate frames 402 are slidingly connected on the round steel I 401, and the two sides of the two-way lead screw 4 are threadedly connected with the two plate frames 402; The upper side of the upper side is fixed to the round steel II 502, the outer frame 503 is slidably connected to the round steel II 502, the wheel 504 is rotatably connected to the outer frame 503, the bottom of the wheel 504 is in contact with the horizontal end surface of the base 501, and the adjustment frame 5 is symmetrically provided with two , the two ends of the two-way lead screw 4 are rotatably connected to the two outer frames 503 respectively, and the two ends of the round steel I 401 are ...

specific Embodiment approach 3

[0047] As shown in the figure, a knife groove 305 is provided on the left side of the processing table 3 . The knife groove 305 is a cutting position, which is convenient for the operator to manually cut or for other cutting equipment to align with the cutting position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com