Rotary mechanical arm of hydraulic manipulator

A technology of rotating machinery and manipulators, applied in the field of manipulators, can solve the problems of high maintenance technical requirements, limited range of activities, and increased purchase costs, and achieve the effect of low maintenance technical requirements, enhanced application scope, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

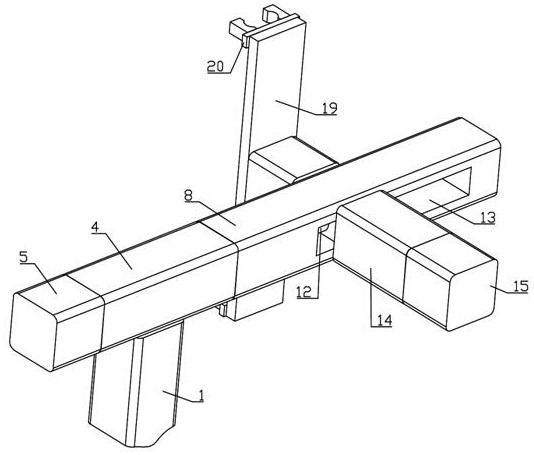

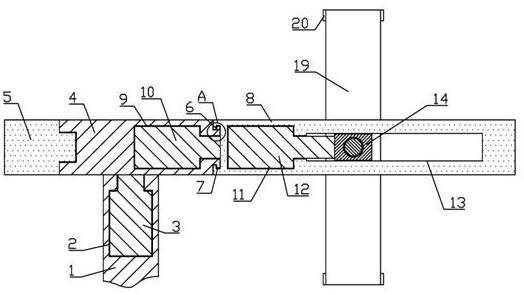

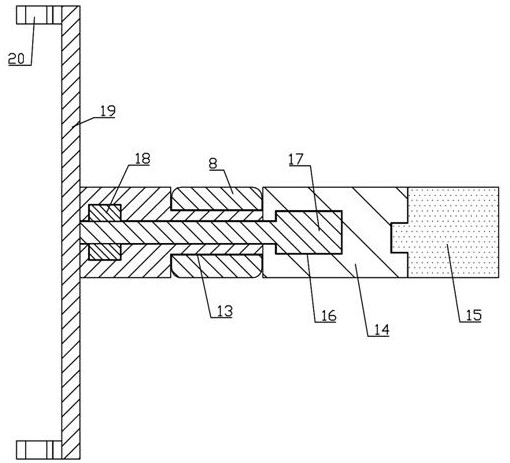

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a rotary mechanical arm of a hydraulic manipulator of the present invention includes a main arm 1, a first mounting groove 2 is arranged in the main arm 1, a first rotating motor 3 is installed in the first mounting groove 2, and a first rotating motor 3 is installed in the first mounting groove 2. The output end of the motor 3 is connected with a first support arm 4, one end of the first support arm 4 is threadedly connected with a first counterweight 5, and the other end is integrally connected with a T-shaped cylinder 6, and the T-shaped cylinder 6 is matched with a first bearing 7, T The font cylinder 6 is rotated and matched with a second arm 8, the first arm 4 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com