Intelligent manufacturing method and system of terazosin hydrochloride capsules

A terazosin hydrochloride and intelligent manufacturing technology is applied in the field of intelligent manufacturing methods and systems of terazosin hydrochloride capsules, which can solve the problems of difficulty in detecting the purity of the main drug, inability to control the purity of the drug meticulously, etc. Content, guaranteed quality and yield, scientific and effective effect of quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The preparation method of embodiment 1 terazosin hydrochloride total mixture

[0063] formula

[0064] Main drug: Terazosin Hydrochloride Accessories: microcrystalline cellulose Magnesium stearate lactose Crospovidone

[0065] Predictive Model Establishment

[0066] Establish a predictive model for terazosin hydrochloride raw materials: 1) input the micrographs of standard terazosin hydrochloride raw materials into the matching subsystem for archiving as a subsequent comparison model. 2) Subsequent microphotography is performed on the extracted sample to obtain a micrograph of the sample. 3) The microphotograph of the sample is intelligently matched with the microphotograph of the archived standard model, and the matching parameters are the particle size and shape of the drug at the same fraction. 4) When the photo matching degree reaches 90% and above, the system can carry out the production operation of the next step of t...

Embodiment 2

[0072] Embodiment 2 produces the intelligent manufacturing system of terazosin hydrochloride capsule

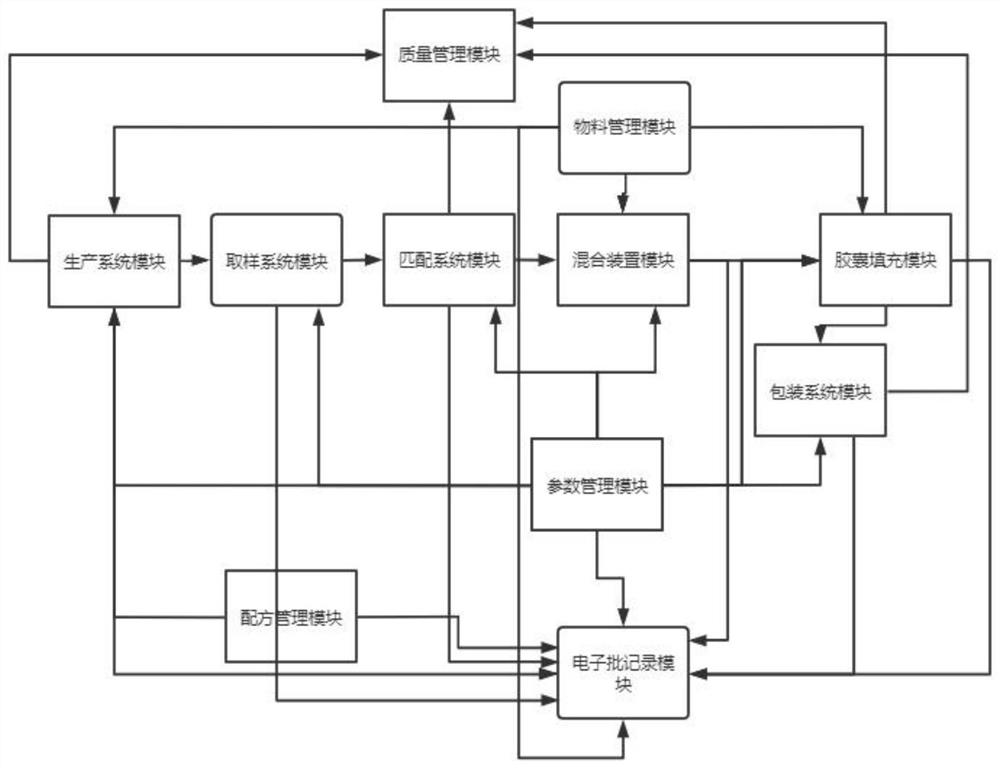

[0073] The invention focuses on improving the quality management subsystem, and introduces a matching subsystem to control the purity of raw materials, thereby improving the quality of medicines. Intelligent manufacturing system of the present invention such as figure 1 Shown include:

[0074] The production subsystem is used to produce terazosin hydrochloride raw material.

[0075] Sampling the subsystem to extract the raw material sample of terazosin hydrochloride in the production subsystem.

[0076] The matching subsystem matches the sample microphotographs extracted by the sampling subsystem with the pre-judgment model graphics, including a microscopic camera for taking the sample microphotographs; a graphic matching module for intelligently analyzing the The degree of matching between the micrograph of the sample and the figure of the pre-judged model.

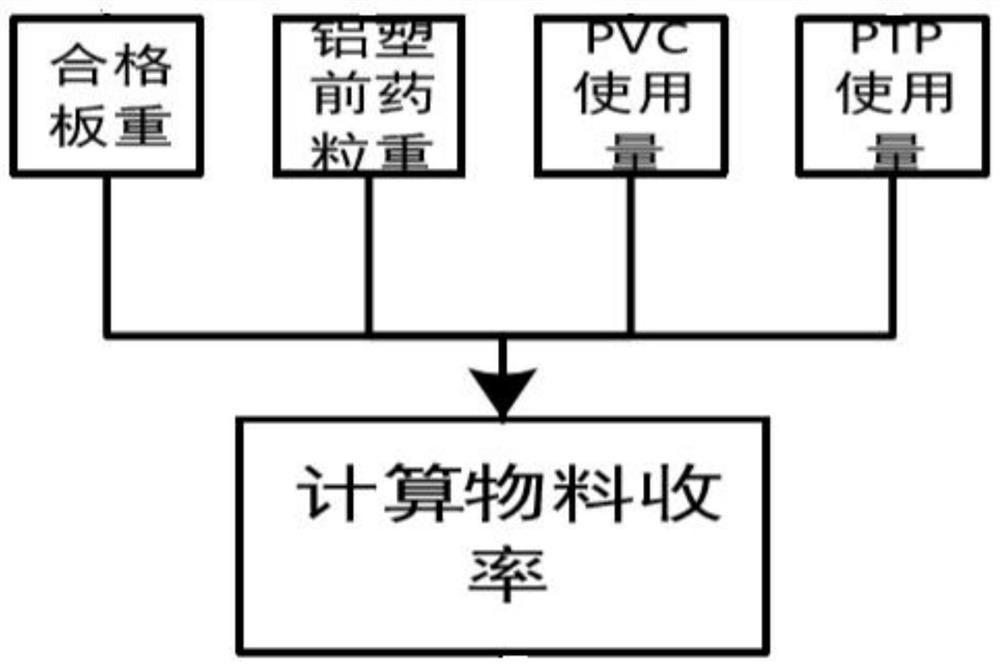

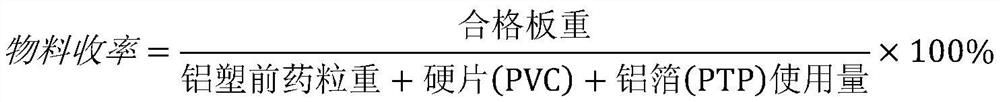

[0077] The ...

Embodiment 3

[0096] Embodiment 3 produces the intelligent manufacturing method of terazosin hydrochloride capsule

[0097] 1. Prediction model establishment

[0098] Establish the prediction model of terazosin hydrochloride raw material:

[0099] 1) Input the micrograph of the standard terazosin raw material into the matching subsystem for archiving as a follow-up comparison model.

[0100] 2) Subsequent photomicrographs of the extracted samples were taken to obtain microphotographs of the samples, and the resolution and magnification of the photos were consistent with those of the model pictures.

[0101] 3) Intelligent matching of sample microphotographs and archived standard model microphotographs.

[0102] 4) When the photo matching degree reaches 90% and above, the system can carry out the production operation of the next step of terazosin hydrochloride total mixture.

[0103] 2. Preparation of terazosin hydrochloride total mixture

[0104] After the matching is qualified, prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com