Composite-structure wind driven generator and power generation system

A technology for wind turbines and composite structures, which is applied in wind power generation, magnetic circuit shape/pattern/structure, and winding conductor shape/pattern/structure, etc., can solve problems such as hindering grid voltage recovery, and improve power density and power generation. Efficiency, safety improvement, effect of reducing excitation current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

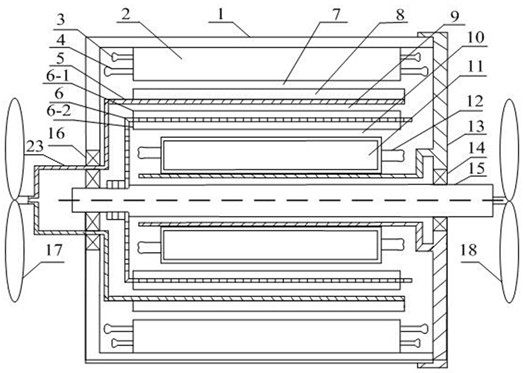

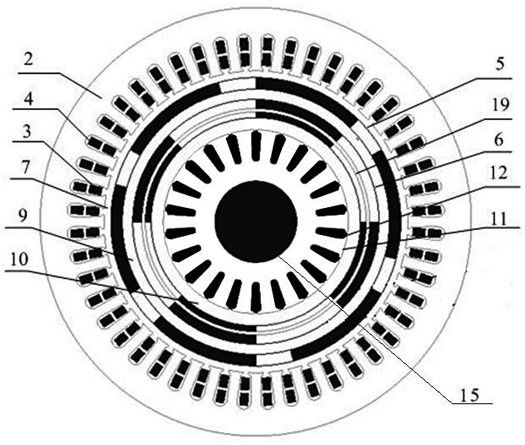

[0033] like Figure 1-2 As shown, a wind power generator with a composite structure includes a casing 1, one side of the casing 1 is fixedly provided with an end cover 13, and the end cover 13 is a part of the casing 1, and the casing 1 is rotatable A rotating shaft 15 is connected, and one end of the rotating shaft 15 is fixedly connected with a second wind turbine 18, and one end of the rotating shaft 15 connected to the second wind turbine 18 is rotationally connected with the end cover 13 through the first bearing 14, and in the casing 1, The outer side of the rotating shaft 15 is provided with an inner stator 11 , a permanent magnet rotor 6 , a magnetic ring rotor 5 and an outer stator 2 in sequence.

[0034] Between the outer stator 2 and the magnetic ring rotor 5 is the first air gap 7, between the magnetic ring rotor 5 and the permanent magnet rotor 6 is the second air gap 9, the permanent magnetic rotor 6 and the inner stator Between 11 is the third air gap 10 .

[...

Embodiment 2

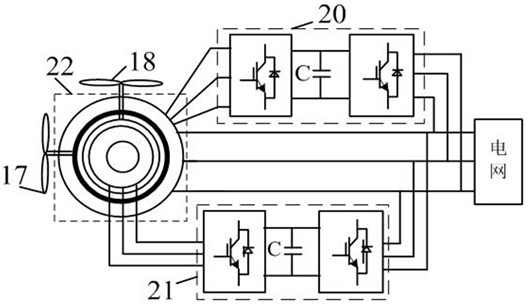

[0045] like Figure 1-3 As shown, a power generation system using a composite structure wind generator includes a composite structure wind generator 22 , an external brushless doubly-fed generator bidirectional converter 20 and an internal permanent magnet generator bidirectional converter 21 .

[0046]The composite structure wind power generator 22 includes a casing 1, one side of the casing 1 is fixedly provided with an end cover 13, the end cover 13 is a part of the casing 1, and the casing 1 is rotatably connected with a rotating shaft 15. One end of the rotating shaft 15 is fixedly connected to the second wind turbine 18, and one end of the rotating shaft 15 connected to the second wind turbine 18 is rotationally connected to the end cover 13 through the first bearing 14. In the casing 1, the rotating shaft The outer side of 15 is provided with an inner stator 11, a permanent magnet rotor 6, a magnetic ring rotor 5 and an outer stator 2 in sequence.

[0047] Between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com